What is a membrane switch?

Time:

2025-06-05

This article introduces what membrane switches are from the aspects of their principles, structures, application scenarios, some special membrane switches, and future trends.

Membrane switch principle

A membrane switch is an interface between the user and the machine, enabling the operator to communicate with a device, instrument or machinery. A membrane switch is a printed electronic circuit that uses pressure to open and close a circuit. Membrane switch circuits are typically screen printed using conductive inks, which are usually made of silver or carbon. Membrane switches, like touch screens and mechanical switches, belong to a family of devices that are considered user interfaces or human machine interfaces (HMIs).

Membrane Switch Construction

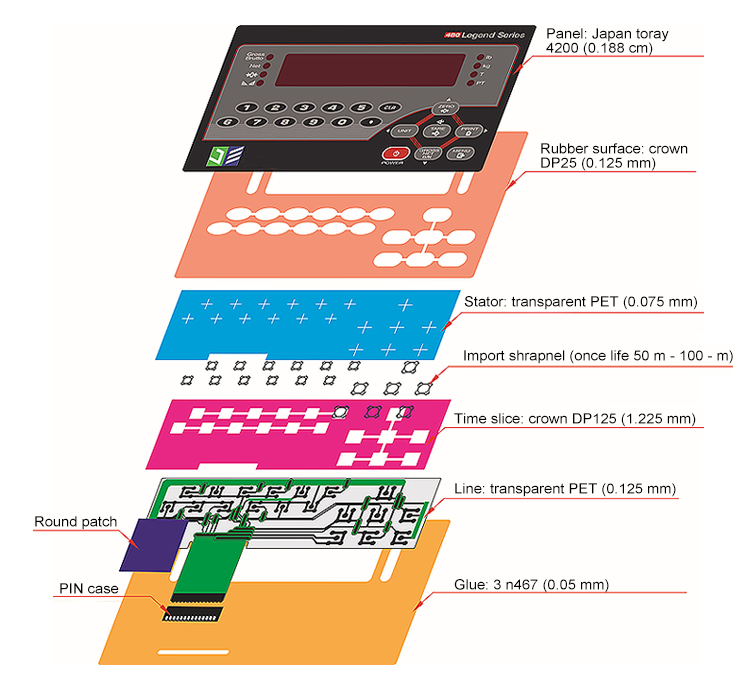

A typical membrane switch assembly is usually made up of six to seven main layers:

Graphic Overlay – Graphic overlays are typically made from polyester, which is the material of choice due to its superior chemical and flex resistance over polycarbonate. JASPER, as a professional membrane switch manufacturer, can use digital printing, screen printing, or a combination of both to ensure you get the color, texture, and finish you require for your Silver Flex membrane switch design.

Overlay Adhesive – The overlay adhesive bonds the graphic overlay to the top circuit layer. This overlay adhesive is usually an acrylic adhesive, which is selected for its durability and ability to maintain adhesion in atypical environments such as moisture.

Top Circuit Layer – Typically a 0.005" - 0.007" heat-stable polyester print layer with silver-filled conductive ink and dielectric ink. This layer can also encapsulate metal domes or integrate multiple domes for tactile feedback, an important design consideration for usability.

Circuit Isolation Layer – This layer separates the top circuit from the bottom circuit, allowing the switch to remain normally open until the key is pressed. The Circuit Isolation Layer is a polyester isolation layer with adhesive on both sides.

Lower Circuit Layer – Typically a 0.005" - 0.007" heat-stable polyester print layer with silver-filled conductive ink and dielectric ink. This layer ends in a flexible tail that serves as an interconnect to the controller PCB or other electronic device.

Back Adhesive Layer – This adhesive layer bonds the entire membrane switch package to the product housing, case, or rigid support board. JASPER can specify the appropriate adhesive type and thickness to bond your membrane keypad to the device.

Rigid Support Layer – This optional layer enhances the structural integrity of the membrane switch assembly. The material can be aluminum, FR-4, steel, etc. This layer can also use mounting hardware such as studs and brackets.

Several variants of membrane switches

Silver Flexible Membrane Switches

Silver flexible membrane switch panels feature screen-printed silver and carbon conductive inks printed onto a flexible polyester layer separated by adhesive spacers. This is the most common design used in flexible custom membrane keypads, providing a slim, space-saving design.

Silver flex circuits are also more cost-effective than electromechanical switch assemblies, and the process of screen-printing conductive silver ink onto a flexible film substrate is potentially less harmful to the environment than chemically etching copper.

Silver Flex membrane switches offer a variety of design options:

-Tactile and non-tactile, with a choice of metal or polyester tactile domes

-Embedded LEDs

-Fiber optic backlighting

-EL (electroluminescent) backlighting

-Hard backings such as aluminum and FR4

-EMI/RFI shielding

-Standard connectors on 0.100" centers, or for ZIF connections

Silver Flex membrane switches also offer a variety of design options with graphic overlays:

-Digital printing, screen printing, or a combination of both

-Pillow or edge embossing

-Clear and/or tinted display windows

-Optional textures

-UV hard-coat finish

Copper Flex membrane switches

The Copper Flex membrane switch construction is ideal for small designs with limited space, dense circuitry, or restricted routing. Copper Flex membrane keypads use silver or copper laminated to a dielectric layer and then etched away.

This switch technology combines the ability of FR4 rigid printed circuit boards to accommodate complex circuit patterns with the flexibility of a membrane switch. Copper flex keypads also offer the advantage of being able to "hard" solder active and passive components into the assembly, making them ideal for high vibration environments.

Copper flex membrane switch panels can be produced using either polyester or polyimide (Kapton) as the substrate, depending on your interface requirements. A very thin layer of copper is pressed onto the flexible film substrate, then chemically etched, leaving copper traces.

Copper flex membrane switches offer you a variety of design options:

-Single and double-sided designs

-Lower resistance and higher conductivity than traditional silver flex membrane switches

-Tight routing capabilities

-Silver flex membrane switches are thin and flexible

-Plating options include tin-lead, nickel, or gold

-Tactile and non-tactile, with metal or polyester tactile domes

-LED lights and other components can be soldered

PCB-based membrane switches

PCB membrane switch construction uses a printed circuit board (PCB) to do double duty in membrane switch design. PCB switches are generally more expensive than silver flex membrane keypads, but can accommodate denser circuit patterns and more complex circuit patterns than silver flex membrane keypads.

PCB membrane switches also allow electronic components to be "hard soldered" to the PCB, whereas membrane switch components are placed using a polymer thick film conductive paste. When using PCB membrane switches, the PCB acts as a rigid backplane and is a very durable and reliable method of integrating LEDs, resistors, LCDs, and other components.

PCB membrane keypads give you a variety of design options:

-Tactile and non-tactile, with metal or polyester tactile domes

-Pillow or edge embossed pattern overlays

-Embedded LEDs soldered directly to the PCB

-Fiber optic backlighting

-EL (electroluminescent backlighting)

-Rigid backplanes such as aluminum and FR4

-EMI/RFI shielding

-Unlimited connector options, soldered directly to the PCB

Of course there are many more, this article only gives examples of special ones. If you have questions or need custom membrane switches and graphic overlays, please contact us. We have 23 years of experience in custom membrane keyboards and are an excellent membrane keyboard manufacturer. Inquiry now to get the factory price.

Application scenarios of membrane switches

Medical devices: the perfect combination of precision and hygiene

In the field of medical devices, cleanliness, accuracy and reliability cannot be compromised. That's why membrane switches are a trusted choice in equipment such as portable ECG monitors, digital infusion pumps and ultrasound control panels. These interfaces must be sealed against contamination, easy to sterilize, and easy for medical staff to operate even under pressure.

To meet these high demands, medical device manufacturers often seek experienced tactile membrane switch manufacturers who understand the importance of meeting FDA and CE standards. At JASPER, we have 1,500 square meters of Class 50,000 cleanrooms, providing a controlled production environment, and each medical-grade switch is designed for safety, hygiene and consistent performance from day one.

Industrial automation: designed for harsh environments

In industrial environments, reliability is not optional, but critical. Membrane switches are an integral part of PLC terminals, robotic systems and factory control panels, which are exposed to dust, oil, moisture and constant vibration. These harsh applications require durable, sensitive and high-performance interfaces.

That’s why JASPER puts every switch through rigorous testing, including salt spray testing and key lifecycle assessments. Whether it’s a high-vibration assembly line or a dusty warehouse control panel, our custom membrane keypads are guaranteed to keep working day after day.

Consumer Electronics: Smart Design Meets Everyday Functionality

From microwaves and coffee makers to home gym equipment, today’s consumers expect tech products to be both stylish and functional. Membrane switches deliver on that, offering sleek, intuitive user interfaces with features like LED backlighting, integrated displays, and full brand customization.

At JASPER, we work closely with consumer electronics brands to develop personalized switch solutions that not only look great, but perform reliably in everyday use. It’s about beauty and reliability.

Instrumentation: Reliable interfaces for precise control

In instruments like signal analyzers, environmental monitors, and lab test systems, precision is critical. These tools require compact, high-performance input solutions that integrate seamlessly into complex PCBs while providing tactile feedback and long-term reliability.

Membrane switches are an ideal choice due to their electromagnetic shielding, wear resistance and user-friendly design. JASPER provides OEMs and engineers with keypads tailored to meet the control and clarity requirements of these critical applications.

Installation and maintenance of membrane switches

Membrane switches are widely favored by OEM manufacturers and equipment integrators for their easy installation and strong adaptability. JASPER's membrane switches are equipped with high-quality 3M adhesive. Simply peel off the release paper and stick directly to a variety of surfaces such as glass, metal or plastic without complicated tools or additional fixings. This self-adhesive installation method not only saves labor time and cost, but also effectively avoids mechanical structure interference, which is suitable for equipment with compact space or high structural requirements.

During installation, it is recommended to operate in a clean, dry and dust-free environment to ensure a firm and lasting bond. During the operation, slowly apply pressure from one end to the other end to fit, which can expel bubbles and improve the appearance texture.

For daily maintenance, membrane switches are waterproof and dustproof. Just wipe the surface gently with a soft damp cloth to restore cleanliness. Avoid using alcohol (unless your custom membrane switch material supports it), strong acids and alkalis, or sharp objects to clean, so as not to damage the printed layer or circuit structure. If the key fails or the response is delayed, it may be caused by circuit aging or material fatigue. You should contact a professional membrane switch manufacturer for inspection and replacement in time to ensure the safety of equipment operation and user operation experience.

At JASPER, our 12-person engineering and technical team provides free and permanent technical support.

Future trends of membrane switches

Membrane switches have shown strong adaptability and market competitiveness in various industries with their light and thin structure, high sealing, durability and cost-effectiveness. Whether it is the cleaning needs in medical equipment or the anti-interference performance in industrial control, membrane switches meet the diverse needs of different customers with their excellent stability and high customization capabilities.

With the continuous development of intelligent manufacturing and human-computer interaction technology, membrane switches will evolve in a smarter, more integrated and more environmentally friendly direction. For example, new designs that combine capacitive touch functions(Capacitive touch switch), LED backlights and flexible circuits will further enhance user experience. As an expert in manufacturing membrane switches, JASPER will continue to pay attention to industry trends, drive customer success with innovation and quality, and promote the continuous upgrading and widespread application of membrane switch technology in the global market.

Relevant news