Table of Contents

Quick Answer: Tactile membrane switches provide physical feedback through a metal dome that creates an audible click and tactile snap, while non-tactile switches offer smooth, silent operation without mechanical feedback. Tactile switches are ideal for applications requiring confirmation of key press (medical devices, industrial controls), while non-tactile switches suit environments needing quiet operation or flat surface designs (consumer electronics, public kiosks).

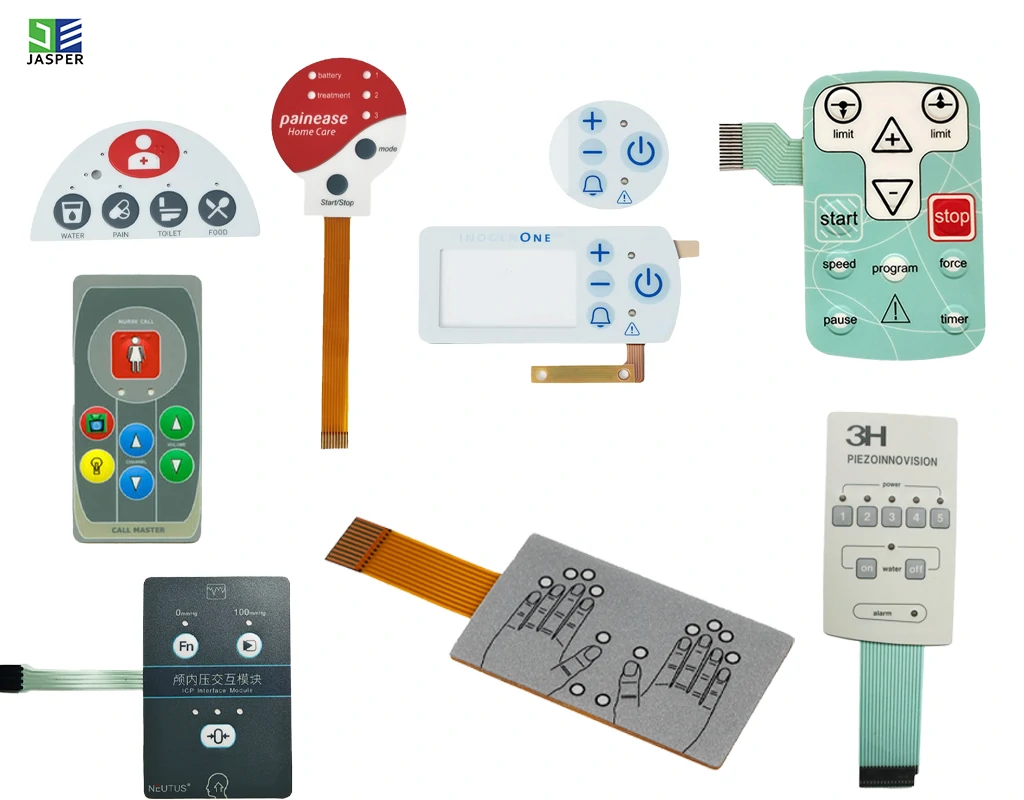

Choosing between tactile and non-tactile membrane switches is one of the most critical decisions in interface design. This choice directly impacts user experience, operational accuracy, and product satisfaction. With over 15 years of manufacturing experience at JASPER, I've helped hundreds of clients select the optimal feedback mechanism for their specific applications.

The fundamental difference lies in the user's sensory experience during operation. Tactile switches provide immediate physical confirmation that a key has been activated, while non-tactile switches rely on visual or auditory feedback systems. Understanding these differences ensures you select the right technology for your product's requirements, environment, and user expectations.

What Is Tactile Feedback in Membrane Switches?

Tactile feedback in membrane switches refers to the physical sensation and audible response a user experiences when pressing a key. This feedback is generated by a metal dome—a precisely engineered component that snaps from a convex to concave shape when sufficient force is applied.

The tactile dome creates three distinct sensory responses:

- Physical sensation: A crisp "snap" felt through the fingertip

- Audible click: A distinctive sound confirming actuation

- Force feedback: Resistance followed by sudden collapse at the actuation point

Non-tactile membrane switches, by contrast, operate without metal domes. They feature a smooth, linear actuation where the flexible circuit layers make contact through direct pressure without mechanical feedback. Users press the switch and receive confirmation only through visual indicators (LEDs) or system responses.

In our manufacturing facility, we work with both types extensively. Tactile switches account for approximately 60% of our production because many industrial and medical applications require the certainty that tactile feedback provides. However, non-tactile switches have been gaining popularity in consumer products where aesthetics and silence are prioritized.

Technical Differences: Tactile vs Non-Tactile

Metal Dome Construction

The primary technical difference between tactile and non-tactile membrane switches is the presence or absence of metal domes in the switch assembly.

Tactile switches incorporate stainless steel domes, typically ranging from 6mm to 12mm in diameter. These domes are precision-formed with specific force ratings (150gf to 500gf being most common) and are positioned between the graphic overlay and the circuit layer. When pressed, the dome collapses and makes contact with the circuit below, completing the electrical connection while simultaneously providing the characteristic "snap" feedback.

Non-tactile switches eliminate the dome layer entirely. The circuit layer itself is flexible, and pressing the graphic overlay directly compresses the circuit layers together. This creates a simpler, thinner construction with typically 0.5-1.0mm less overall thickness compared to tactile assemblies.

We manufacture both types in our facility, and I can tell you that tactile switches require more precise assembly. The dome must be perfectly aligned with the circuit contact, and the adhesive must be carefully applied to prevent dome migration during the product's lifetime.

Actuation Mechanics

The actuation mechanics differ fundamentally between the two types:

Tactile actuation follows a non-linear force curve. As pressure increases, the dome resists until reaching its "snap point"—typically at 60-70% of the dome's rated force. At this point, the dome collapses suddenly, requiring minimal additional force to complete the actuation. This creates the distinctive tactile sensation and produces an audible click (typically 45-55 dB).

Non-tactile actuation follows a linear force progression. Pressure increases steadily until the circuit layers make contact. There's no sudden collapse or snap—just smooth, gradual compression. The switch actuates silently, typically at lower forces (50-150gf) compared to tactile switches.

From a reliability standpoint, tactile switches are rated for 1-5 million actuations, while non-tactile switches can achieve 10+ million actuations due to their simpler construction and lack of mechanical components that can fatigue.

Force-Displacement Curves

The force-displacement curve is the graphical representation of how much force is required at each point of the key press travel:

Tactile force curve: Shows a sharp peak followed by a sudden drop when the dome collapses. The peak force (actuation force) occurs at approximately 0.3-0.5mm travel, followed by minimal resistance for the remaining travel distance. This creates the "positive feedback" sensation that users can feel.

Non-tactile force curve: Displays a gradual, linear increase in force throughout the entire travel distance. There's no peak or sudden drop—just steady resistance until the circuit layers make contact, typically at 0.2-0.4mm travel depth.

In applications where users wear gloves or operate equipment in high-vibration environments, the pronounced force curve of tactile switches provides significantly better feedback and reduces input errors.

Performance Comparison

Here's a comprehensive comparison of key performance characteristics:

| Characteristic | Tactile Switches | Non-Tactile Switches |

|---|---|---|

| Actuation Force | 150-500gf (typical: 250-350gf) | 50-150gf (typical: 80-120gf) |

| Feedback Type | Physical snap + audible click | Visual/software confirmation only |

| Life Cycle | 1-5 million actuations | 5-10+ million actuations |

| Noise Level | 45-55 dB (audible click) | Silent operation |

| Switch Thickness | 2.0-3.5mm (includes dome) | 1.0-2.0mm (no dome layer) |

| Travel Distance | 0.3-0.6mm (to snap point) | 0.2-0.4mm (to contact) |

| Response Time | Instant physical confirmation | Depends on system response |

| Relative Cost | Baseline (100%) | 15-25% lower |

| Blind Operation | Excellent (physical feedback) | Poor (requires visual confirmation) |

| Gloved Use | Excellent (clear feedback) | Moderate (reduced sensation) |

This comparison reveals that neither type is universally superior—each excels in specific applications. Tactile switches provide certainty and durability for demanding environments, while non-tactile switches offer sleeker designs and longer operational life for high-frequency applications.

Application Scenarios

Best Applications for Tactile Switches

Tactile membrane switches are the preferred choice in scenarios where operational certainty and user confidence are paramount:

Medical devices: Hospital equipment, patient monitors, infusion pumps, and diagnostic machines benefit from tactile feedback because healthcare professionals often operate controls without looking directly at them. The physical confirmation reduces input errors in critical situations. We've manufactured tactile switches for ventilators where every button press must be unmistakably confirmed.

Industrial control panels: Factory automation, machine controls, and process monitoring systems operate in noisy, high-vibration environments. The tactile snap provides confirmation that can be felt even when wearing thick gloves or when ambient noise makes audible feedback unreliable. One of our automotive manufacturing clients specifically requires 350gf tactile switches for their assembly line controls.

Test and measurement equipment: Oscilloscopes, multimeters, and laboratory instruments require precise input. Tactile feedback helps technicians navigate menus and enter data accurately without repeatedly checking the display.

Emergency response systems: Fire alarm panels, security systems, and emergency shutdown controls benefit from the definitive "I pressed this" confirmation that tactile switches provide. In high-stress situations, this physical feedback is crucial.

Military and aerospace: Rugged environments with extreme temperatures, vibration, and pressure on operators to make accurate inputs make tactile switches the standard choice. The positive feedback reduces training requirements and operational errors.

Best Applications for Non-Tactile Switches

Non-tactile membrane switches excel in applications prioritizing aesthetics, silence, or high-frequency operation:

Consumer electronics: Home appliances, remote controls, and consumer gadgets often use non-tactile switches for their sleek, flat appearance and silent operation. A coffee machine or microwave oven in a residential kitchen benefits from quiet button presses that don't disturb the household.

Public kiosks: Information terminals, ticketing machines, and self-service kiosks handle thousands of daily activations. The extended life cycle of non-tactile switches (10+ million actuations) reduces maintenance costs. The flat, smooth surface is also easier to clean in high-traffic public spaces.

Point-of-sale systems: Retail environments benefit from silent operation during transactions. Non-tactile switches eliminate the clicking sound that can be perceived as annoying by customers during peak hours.

Audio/video production: Recording studios, broadcast facilities, and production environments require silent control surfaces. Non-tactile switches allow operators to make adjustments without creating noise that might be captured by sensitive microphones.

Hospitality and spa equipment: Hotel room controls, spa equipment, and wellness devices prioritize quiet, relaxing environments where the clicking sound of tactile switches would be inappropriate.

Gaming peripherals: While some gaming applications prefer tactile feedback, many modern gaming interfaces use non-tactile switches with RGB backlighting for aesthetic appeal and rapid, silent input during competitive play.

Cost Considerations

The cost difference between tactile and non-tactile membrane switches stems from materials and manufacturing complexity:

Material costs: Tactile switches require metal domes (stainless steel), which add approximately $0.05-$0.20 per switch depending on dome size and force rating. For a 12-key panel, this represents $0.60-$2.40 in additional component costs. While this may seem modest, it becomes significant in high-volume production.

Assembly complexity: Tactile switches require an additional manufacturing step—dome placement and adhesive application. This increases labor costs by approximately 15-20% and introduces additional quality control requirements to ensure proper dome alignment.

Tooling: Both types use similar tooling for die-cutting and printing, so tooling costs are comparable. However, tactile switches may require specialized fixtures for dome placement, adding $200-$500 to initial setup costs.

Testing: Tactile switches require force testing to verify actuation force meets specifications. Non-tactile switches need simpler resistance testing. This adds minimal cost but extends production time slightly.

Lifecycle cost: While tactile switches cost more initially, their shorter lifecycle (1-5 million vs. 10+ million actuations) may increase replacement costs in high-frequency applications. For a public kiosk with 5,000 daily activations, a tactile switch might require replacement in 1-2 years, while a non-tactile switch could last 5+ years.

In our experience at JASPER, clients should budget approximately 15-25% more for tactile switches when comparing equivalent specifications. However, this premium is often justified by the improved user experience and reduced input errors in critical applications.

How to Choose: Decision Framework

Use this decision framework to determine which type best suits your application:

Step 1: Assess Operating Environment

- Will users operate the switch without looking? → Tactile

- Is the environment noisy or high-vibration? → Tactile

- Will users wear gloves? → Tactile

- Is quiet operation essential? → Non-tactile

- Is the environment temperature-extreme? → Tactile (domes perform better across temperature ranges)

Step 2: Consider Usage Patterns

- Frequency: High-frequency (>1 million/year) → Non-tactile for longer life

- Criticality: Safety-critical inputs → Tactile for confirmation

- User expertise: Trained professionals → Tactile; General public → Either (depends on other factors)

Step 3: Evaluate Design Priorities

- Thin profile required (<2mm)? → Non-tactile

- Premium feel desired? → Tactile

- Minimalist aesthetic? → Non-tactile

- Industrial/rugged appearance? → Tactile

Step 4: Budget Constraints

- Cost-sensitive project? → Non-tactile

- Willing to pay 15-25% premium for better UX? → Tactile

- High replacement costs concern? → Non-tactile (longer life)

Step 5: Regulatory Requirements

- Medical device standards requiring confirmed input? → Tactile

- Accessibility requirements? → Tactile (better for visually impaired users)

- IP rating requirements? → Both can achieve IP65+, but non-tactile slightly easier to seal

Based on 15 years of manufacturing experience, I recommend tactile switches when operational certainty is the primary concern, and non-tactile switches when aesthetics, cost, or lifecycle are the driving factors. When in doubt, consider building prototypes of both types for user testing—the feedback from actual users in your target environment is invaluable.

What is the main difference between tactile and non-tactile membrane switches?

The main difference is the presence of a metal dome in tactile switches that creates physical and audible feedback when pressed, versus non-tactile switches that operate smoothly and silently without mechanical feedback. Tactile switches provide a distinctive "snap" sensation and click sound, while non-tactile switches rely on visual or software confirmation of activation.

Which type of membrane switch lasts longer?

Non-tactile membrane switches typically last longer, rated for 5-10+ million actuations compared to 1-5 million for tactile switches. This is because non-tactile switches have simpler construction without metal domes that can fatigue over time. For high-frequency applications like public kiosks or point-of-sale terminals, non-tactile switches offer better lifecycle value.

Are tactile membrane switches better for medical devices?

Yes, tactile membrane switches are generally preferred for medical devices because they provide immediate physical confirmation of input, which is critical in healthcare environments. Medical professionals often operate equipment without direct visual attention, and the tactile feedback reduces input errors in critical situations. Many medical device standards also favor interfaces that provide positive feedback confirmation.

Can non-tactile switches work with gloves?

Non-tactile switches can work with gloves, but the user experience is reduced because there's no physical feedback to confirm the button press through the glove material. Tactile switches are strongly preferred for gloved operation because the user can feel the distinctive snap even through thick gloves. For industrial environments where glove use is standard, tactile switches provide significantly better usability.

How much more do tactile membrane switches cost?

Tactile membrane switches typically cost 15-25% more than equivalent non-tactile switches. The additional cost comes from the metal domes (approximately $0.05-$0.20 per switch), more complex assembly requirements, and additional quality control testing. For a 12-key panel, expect to pay $0.60-$2.40 more in component costs. While this premium may seem modest, it becomes significant in high-volume production.

Which type is better for consumer products?

Non-tactile membrane switches are often preferred for consumer products because they offer silent operation, sleeker aesthetics, and lower cost—all important factors in consumer markets. They create flatter, more modern-looking interfaces and eliminate clicking sounds that might be perceived as annoying in home environments. However, some premium consumer products use tactile switches to provide a higher-quality feel and better user experience, so the choice depends on your product positioning and target market.

References

- ASTM F1545 - Standard Test Method for Measurement of Switch Actuation Force

- IEC 60529 - Degrees of Protection Provided by Enclosures (IP Code)

- ISO 13485 - Medical Devices Quality Management Systems

- JASPER Internal Testing Data - Quality Assurance Labs (2010-2025)

- Industry Standards for Tactile Dome Specifications - Snaptron Corporation