Car Seat Occupancy Sensor

keyword:

Product description

Automotive Seat Occupancy Sensors (OCS) Product Description

Product Overview

As automotive safety technology continues to innovate, automotive seat occupancy sensors (OCS) are becoming more and more important as a key component in enhancing the passive safety performance of automobiles, and Jasper, as an outstanding manufacturer of automotive seat occupancy sensors, provides critical data for automotive safety systems to safeguard drivers and passengers in all aspects of transportation.

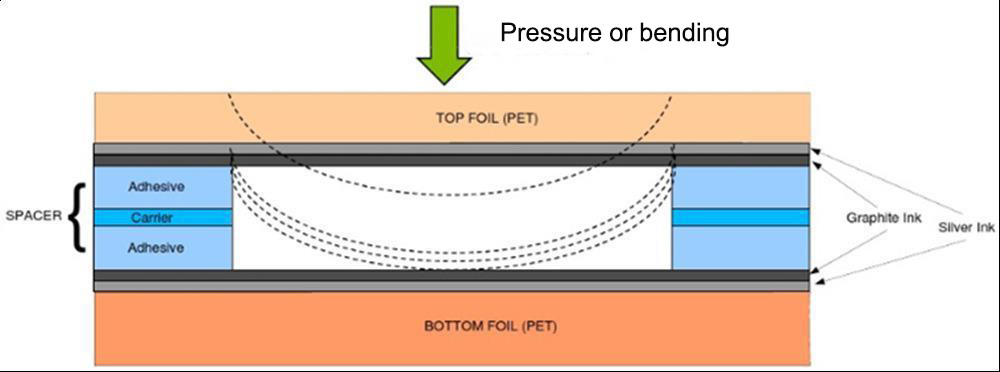

Working Principle

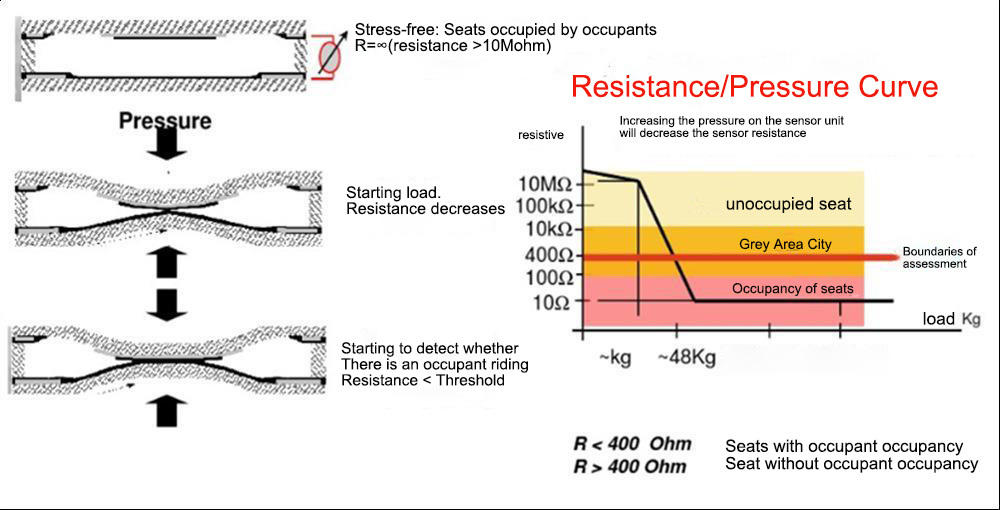

- Pressure Sensing: The high-performance pressure sensor inside the seat cushion can convert the pressure change generated by human body pressure or gravity into an electrical signal. Like capacitive through the capacitance value, resistive through the resistance value of the change in the determination of pressure, in order to determine whether the seat is occupied or not.

- Capacitive Sensor: Detects the change in capacitance value triggered by the change in electric field on the seat surface when a person approaches or touches the seat. Its high sensitivity can sense the passenger's approach in advance and provide support for the early response of vehicle-related functions.

- Infrared Sensor: Actively emits infrared rays, which are reflected back when they meet the human body. The sensor receives the reflected signal and converts it into an electrical signal to determine whether the seat is occupied. Thanks to this principle of operation, infrared sensors can reliably and efficiently detect seat occupancy.

- Ultrasonic Sensing: Based on the principle of ultrasonic propagation and reflection, it determines the position of the object by measuring the time and speed of the reflected wave, and the multiple sensor arrays can realize 360-degree detection.

Product Advantages

- Accurate Detection: Integrating multiple technologies, it accurately recognizes seat occupancy and passenger weight with minimal error.

- Rapid Response: Millisecond response, can instantly transfer the seat status information to the safety system.

- Stable and Reliable: It has been tested in extreme environments such as high and low temperatures, vibration, waterproof and dustproof, and can be adapted to a variety of harsh driving environments.

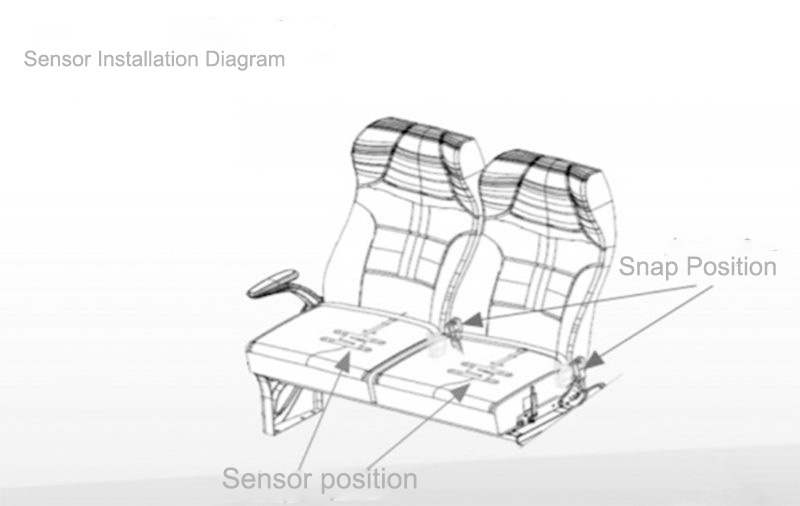

- Strong Compatibility: It can be seamlessly connected with most of the automobile safety systems on the market, and is easy to install.

Application Scenarios

- Airbag Control: In case of a collision, adjust the airbag ejection force according to the weight of the passenger monitored by OCS to ensure safety.

- Seat Belt Reminder: Detecting passengers not fastening seat belts, triggering timely reminder to avoid ineffective prompts.

- Child Seat Protection: Works with ISOFIX device to recognize the state of child seat use and adjust the safety system settings.

- Pre-Tensioned Seat Belt Adjustment: Optimize the pre-tensioning strength according to the passenger's weight and sitting position, and collaborate with other safety devices for protection.

Technical Specifications

| Item | Parameter |

|---|---|

| Maximum Operating Voltage | 5V |

| Insulation Resistance | ≥100MΩ |

| Maximum Operating Current | 20mA |

| Base Material Voltage | <12DC |

| Contact Resistance | 2K DVC |

| Response Time | ≤1S |

| Insulation Leakage Voltage | 1VDC |

| Power-On Time | ≤50MΩ |

| Key Lifetime | ≥1,000,000 times |

| Key Travel | 0.30-0.88mm |

| Contact Pressure | 60g (customizable) |

| Key Sensitivity | 40% (CF/CR) |

| Operating Temperature | -30°C ~ +70°C |

| Storage Temperature | -40°C ~ +85°C |

| Salt Spray Test | 48 hours |

| UV Aging | 24 hours |

| Thickness/Outer Size | Customizable |

Conclusion

With superior performance, reliable quality and wide applicability, as well as customizable car seat occupancy sensors, JASPER OCS has become a trusted name in automotive travel safety.

More seat sensor standard products see PDF : Jasper-seat-sensor-catalogue

your supplier of user interface products

Car Occupancy Seat Sensor FAQs

1. How does JASPER's OCS improve the return on investment of automotive safety systems?

Our OCS can improve the response accuracy of safety systems and effectively reduce false triggering rates and rework costs. Its integrated piezoresistive, capacitive, infrared and ultrasonic technologies ensure high-precision recognition of different body shapes and child seats, thereby improving the safety assessment (NCAP) of vehicle brands by reducing safety insurance compensation rates and improving user satisfaction.

2. Can OEM/ODM or JDM customized development be supported?

Yes. We provide three modes:

OEM: Produce standard sensors according to customer specifications;

ODM: Adjust size, sensitivity, and output protocol according to customer needs;

JDM: Provide an integrated solution from design to vehicle-level matching, and jointly develop with customer ECU/E-box ports and signal interfaces to shorten development cycles and reduce system risks.

3. What models or system platforms does JASPER OCS adapt to?

Widely compatible with airbag and seat control modules from mainstream vehicle manufacturers in Europe, the United States, Japan and China. It can output analog voltage, CAN signal, and LIN protocol to meet the access requirements of master control units such as Bosch, Continental, Denso, and Autoliv.

4. Certification and quality management?

International certification: ISO 9001, IATF 16949, RoHS, and TUV certifications;

Test approval: high/low temperature cycle testing, salt spray, vibration shock, and UV aging, all meet and exceed IATF standards;

Independent intellectual property rights: 10+ industry patents to improve product stability and repeatability.

5. Production capacity and production capacity guarantee?

Production capacity scale: Up to 6,000 pieces can be printed per hour, and the monthly output reaches millions;

Delivery time controllable: standard products are generally delivered in 7-14 days, and customized products are delivered in 4-6 weeks;

Quality control: full-process SPC, FMEA, and 100% final inspection are adopted to eliminate batch defects.

6. Who is responsible for system integration?

We can provide end-to-end support from hardware to software, including prototype test installation, vehicle warehouse adjustment and signal output debugging configuration. Our engineering team will guide customers to complete DFMEA/DTM/DP tests to ensure that the sensor meets the vehicle safety system acceptance.

7. Do you provide after-sales support and emergency response to faults?

Warranty period: Provide 12-month warranty and irregular after-sales support based on component quality;

Fault response mechanism: Respond within 24 hours and provide fault analysis report within 72 hours;

Training support: Customers can apply for 1 free engineering training/on-site support service (2 people/2 days).

8. Can you provide POC or small batch testing for specific projects?

Support. We provide preliminary samples for pilot projects (minimum order quantity 100 pieces), and support vehicle environmental testing, TÜV project certification, NCAP simulated collision testing, etc.

Related products

Online Message