Table of Contents

- Introduction

- What Makes a Membrane Switch "Medical Grade"?

- Regulatory Compliance Requirements

- Material Selection for Medical Applications

- Critical Design Requirements

- Sterilization and Disinfection Compatibility

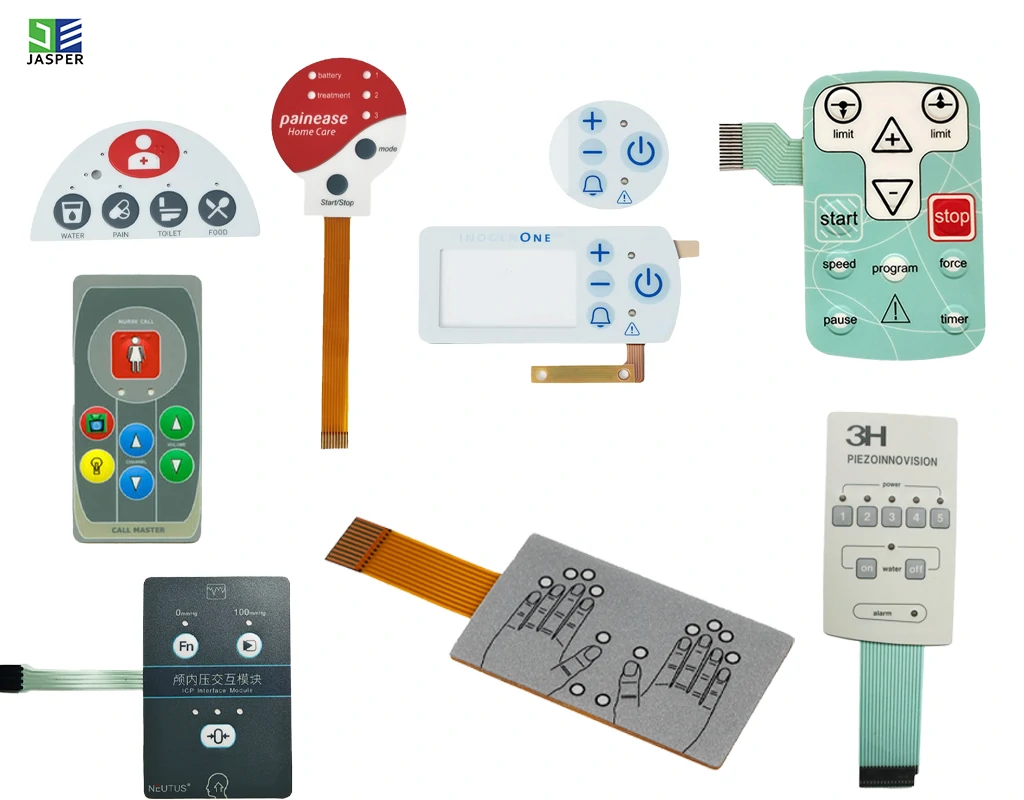

- Common Medical Device Applications

- Testing and Validation Process

- Cost Considerations

- Frequently Asked Questions

Quick Answer: Medical grade membrane switches are user interface components designed and manufactured to meet strict healthcare regulatory standards including ISO 13485, FDA 21 CFR Part 820, and biocompatibility testing (ISO 10993). They feature antimicrobial materials, chemical-resistant surfaces compatible with hospital-grade disinfectants, sealed construction (IP65-IP68), and materials that withstand repeated sterilization cycles—making them essential for patient monitors, infusion pumps, diagnostic equipment, and surgical devices.

Designing membrane switches for medical devices requires navigating complex regulatory landscapes while meeting demanding performance requirements. With over 15 years of experience manufacturing medical-grade interfaces at JASPER, I've worked with medical device OEMs worldwide to develop compliant, reliable switch solutions for life-critical applications.

The stakes in medical device manufacturing are uniquely high. A failed switch in a ventilator or infusion pump can directly impact patient safety. This guide provides comprehensive technical and regulatory insights to ensure your medical interface meets all compliance requirements while delivering reliable performance in demanding healthcare environments.

What Makes a Membrane Switch "Medical Grade"?

The term "medical grade" isn't merely marketing—it represents adherence to specific regulatory frameworks, material standards, and manufacturing controls that distinguish medical components from commercial or industrial equivalents.

A medical grade membrane switch must satisfy four fundamental criteria:

- Regulatory compliance: Manufactured in ISO 13485-certified facilities following FDA Quality System Regulations (QSR) or equivalent international standards

- Material biocompatibility: All patient-contact or near-contact materials tested per ISO 10993 for cytotoxicity, sensitization, and irritation

- Chemical resistance: Compatible with hospital-grade disinfectants (isopropyl alcohol, bleach solutions, quaternary ammonium compounds) without degradation

- Traceability and documentation: Complete material certificates, lot traceability, and design history files (DHF) for regulatory audits

At JASPER, approximately 35% of our production serves medical device manufacturers. We maintain ISO 13485:2016 certification and follow strict cleanroom protocols for medical assembly. Every medical-grade switch we produce includes complete documentation packages required for FDA 510(k) submissions or CE marking under the Medical Device Regulation (MDR).

The distinction between commercial and medical grade becomes critical during regulatory review. Using non-compliant components can delay product launches by 6-18 months while manufacturers scramble to validate replacement parts and update regulatory submissions.

Regulatory Compliance Requirements

ISO 13485 Certification

ISO 13485 is the international standard for quality management systems specific to medical device manufacturing. Unlike ISO 9001 (general quality management), ISO 13485 emphasizes risk management, design controls, and traceability throughout the product lifecycle.

For membrane switch manufacturers serving medical OEMs, ISO 13485 certification demonstrates:

- Process validation: Manufacturing processes are validated and consistently produce conforming products

- Design controls: Formal design and development procedures with verification and validation stages

- Risk management: Implementation of ISO 14971 risk management processes

- Supplier controls: Qualified supplier programs ensuring material consistency

- Traceability: Lot tracking from raw materials through finished goods

When evaluating membrane switch suppliers, request copies of their ISO 13485 certificates and ask about their audit history. Manufacturers with multi-year certification histories and clean audit records demonstrate consistent compliance.

FDA Requirements

For medical devices sold in the United States, manufacturers must comply with FDA 21 CFR Part 820 (Quality System Regulation). While the membrane switch itself isn't typically the "device," it becomes a critical component requiring full documentation.

Key FDA requirements affecting membrane switch procurement:

- Design History File (DHF): Comprehensive documentation of design inputs, outputs, verification, and validation

- Device Master Record (DMR): Complete manufacturing specifications, drawings, and procedures

- Component qualification: Suppliers must be qualified and monitored per the OEM's supplier control procedures

- Change control: Any design or material changes require formal change orders and impact assessment

From our experience at JASPER, medical device OEMs typically require 4-8 weeks for initial component qualification, including facility audits, first article inspection, and documentation review. Budget adequate time for this process when developing new medical products.

Biocompatibility Standards

ISO 10993 is the internationally recognized standard for biological evaluation of medical devices. Even though membrane switches rarely have direct patient contact, components on devices that touch patients or are in the patient environment require biocompatibility assessment.

The testing requirements depend on contact classification:

| Contact Type | Duration | Required Tests (ISO 10993) |

|---|---|---|

| Surface contact (skin) | Limited (≤24 hrs) | Cytotoxicity, Sensitization, Irritation |

| External communicating (indirect) | Prolonged (>24 hrs to 30 days) | Cytotoxicity, Sensitization, Irritation, Systemic toxicity |

| Non-contact (environmental) | Any | Typically cytotoxicity only |

Most membrane switches on medical equipment fall into the "non-contact" or "surface contact-limited" categories, requiring cytotoxicity testing at minimum. JASPER maintains biocompatibility test reports for standard medical-grade materials (polycarbonate overlays, medical-grade adhesives) to accelerate customer qualification timelines.

Material Selection for Medical Applications

Material selection for medical membrane switches requires balancing regulatory compliance, chemical resistance, and long-term reliability. The wrong material choice can result in switch failure, regulatory rejection, or patient safety issues.

Graphic Overlay Materials

Polycarbonate (PC) - Most Common Choice

- Excellent chemical resistance to alcohols, bleach solutions, and disinfectants

- Superior durability (scratch-resistant, impact-resistant)

- Available in medical-grade formulations with biocompatibility certifications

- Typical thickness: 0.175mm - 0.375mm for medical applications

- Withstands autoclaving (limited cycles, up to 121°C)

Polyester (PET) - Budget Alternative

- Lower cost than polycarbonate

- Good chemical resistance (but degrades faster with repeated bleach exposure)

- Less impact-resistant (can crack with aggressive cleaning)

- Suitable for non-critical, single-patient devices

For life-critical devices (ventilators, infusion pumps, patient monitors), we recommend polycarbonate overlays with hard-coat treatments for extended service life. We've seen polyester overlays fail within 6-12 months in high-traffic hospital environments due to aggressive cleaning protocols.

Adhesive Selection

Medical-grade adhesives must provide reliable bonding while resisting chemical degradation:

- 3M 467MP/468MP: Medical-grade acrylic adhesives with skin contact biocompatibility

- 3M 9731/9832: High-performance acrylic for demanding environmental exposure

- Silicone adhesives: Excellent biocompatibility but lower initial tack (requires precise assembly)

Standard commercial adhesives often contain additives that fail cytotoxicity testing. Always specify medical-grade adhesives and request material safety documentation.

Circuit Materials

Conductive inks for medical circuits must maintain stable resistance across temperature ranges and resist oxidation:

- Silver ink: Standard choice, excellent conductivity, cost-effective

- Silver-carbon blends: Better resistance stability over time

- Copper circuits: Used in high-current applications (defibrillators), requires protective coatings

All circuit materials should be RoHS-compliant and free from prohibited substances under EU MDR Annex I.

Critical Design Requirements

Medical membrane switches face unique design challenges beyond standard commercial applications. These requirements directly impact patient safety and device usability in high-stress clinical environments.

Cleanability and Surface Design

Hospital-acquired infections (HAIs) are a critical concern. Medical device surfaces must be cleanable without degradation:

- Smooth, non-porous surfaces: Avoid textured finishes that trap bacteria or fluids

- Sealed edges: Complete perimeter sealing prevents fluid ingress during cleaning

- Chemical-resistant coatings: Hard-coat or anti-microbial treatments extend service life

- Minimal crevices: Avoid deep embossing or design features that complicate cleaning

In our testing, membrane switches with smooth polycarbonate surfaces and IP65+ sealing maintained functionality after 500+ cleaning cycles with 10% bleach solution—far exceeding typical device service life.

Environmental Sealing

Medical environments expose devices to blood, saline, cleaning chemicals, and bodily fluids. Proper sealing is essential:

- IP65 minimum: Protection against water jets (for washdown cleaning)

- IP67/IP68 preferred: Immersion protection for surgical or procedural devices

- Sealed connectors: Tail sealing or overmolded connectors prevent fluid wicking

Tactile Feedback Requirements

Healthcare professionals often operate medical equipment without direct visual attention while focusing on patients. Tactile feedback is critical:

- Metal dome switches: Provide definitive actuation confirmation (250-350gf typical for medical)

- Consistent actuation force: ±50gf tolerance across all keys for predictable operation

- Glove-compatible operation: Higher actuation forces and larger button areas accommodate latex/nitrile gloves

For emergency stop functions or critical medication delivery controls, we recommend 350-450gf tactile domes to prevent accidental activation while ensuring deliberate presses are unmistakable.

Backlighting and Visibility

Medical devices operate in diverse lighting conditions—from darkened patient rooms to brightly-lit surgical suites:

- LED backlighting: Adjustable brightness for day/night operation

- High-contrast graphics: Clearly visible under all ambient lighting

- Color-coding: Red for alerts/stops, green for confirms, following IEC 60601 guidance

- Anti-glare treatments: Reduce reflections under surgical lights

Sterilization and Disinfection Compatibility

Medical devices undergo various sterilization and disinfection processes depending on their use classification. Membrane switches must withstand these processes without functional or cosmetic degradation.

Common Sterilization Methods

Chemical Disinfection (Most Common)

- Isopropyl alcohol (70-90%): Daily cleaning—all medical switches must withstand

- Sodium hypochlorite (bleach, 0.5-10%): High-level disinfection—requires polycarbonate or treated surfaces

- Quaternary ammonium compounds: Routine surface disinfection

- Hydrogen peroxide vapor: Room-level decontamination—materials must resist oxidation

Autoclave Sterilization (Limited Applications)

- Steam at 121°C or 134°C: Surgical instruments and reusable devices

- Membrane switches: Special medical-grade polycarbonate and high-temp adhesives required

- Cycle limitations: Typically 10-50 cycles before adhesive degradation

- Alternative: Removable/replaceable membrane overlays for long-term surgical equipment

Ethylene Oxide (EtO) Sterilization

- Low-temperature sterilization for sensitive electronics

- Material compatibility: Most membrane materials tolerate EtO

- Outgassing requirements: 24-48 hour degassing period post-sterilization

Antimicrobial Treatments

Some medical applications benefit from antimicrobial coatings or materials:

- Silver-ion additives: Embedded in polycarbonate for continuous antimicrobial effect

- Surface treatments: Photocatalytic coatings (titanium dioxide) that actively kill bacteria

- Effectiveness: Reduces bacterial load by 99.9% in standardized testing (JIS Z 2801)

While antimicrobial treatments provide added protection, they don't replace proper cleaning protocols. We recommend them for high-touch devices in infectious disease units or immunocompromised patient environments.

Common Medical Device Applications

Medical grade membrane switches serve diverse healthcare equipment across clinical, diagnostic, and therapeutic categories:

Critical Care Equipment

- Ventilators: IP68 sealing, high-reliability tactile switches, autoclaving compatibility for reusable components

- Infusion pumps: Glove-compatible operation, drug library access controls, alarm acknowledgment

- Patient monitors: Multi-parameter displays, alarm management, parameter adjustment controls

- Defibrillators: Emergency-accessible controls, high-contrast graphics, sealed against bodily fluids

Diagnostic Equipment

- Ultrasound systems: Membrane keypads for data entry, probe controls, imaging parameter adjustment

- Blood analyzers: Sample processing controls, cleanroom-compatible materials

- ECG/EKG machines: Lead selection, test initiation, report printing controls

Surgical and Procedural Devices

- Electrosurgical units: Power level controls, mode selection, safety interlocks

- Surgical lights: Intensity adjustment, focus controls, sterilizable touchpoints

- Endoscopy equipment: Camera controls, light source adjustment, image capture

Home Healthcare and Patient Monitoring

- Glucose meters: Simple interface, low power, clear visual feedback

- CPAP machines: Sleep apnea therapy controls, ramp functions, humidity adjustment

- Blood pressure monitors: Start/stop controls, memory recall, user selection

Each application category has unique regulatory pathways. Class III devices (life-sustaining equipment like ventilators) face the most stringent requirements, while Class I devices (manual surgical instruments) have simpler regulatory paths.

Testing and Validation Process

Comprehensive testing validates that medical membrane switches meet design specifications and regulatory requirements. At JASPER, our medical validation process includes:

Design Verification Testing

- Actuation force testing: Verify tactile domes meet specified force ±10% tolerance across production lots

- Environmental sealing: IP rating validation per IEC 60529 (water immersion, dust exposure)

- Electrical testing: Circuit resistance, contact bounce, switch life cycle (1-5 million actuations)

- Dimensional verification: Ensure assembly fits within device envelope with proper tolerances

Chemical Resistance Testing

- Disinfectant exposure: 100+ cleaning cycles with specified hospital disinfectants

- Functional verification: Actuation force stability, graphic integrity, adhesion retention

- Accelerated aging: Elevated temperature exposure to simulate 5-year service life

Biocompatibility Testing

- Cytotoxicity (ISO 10993-5): Cell culture testing for toxic extract leachables

- Sensitization (ISO 10993-10): Guinea pig testing for allergic potential (if skin contact)

- Irritation (ISO 10993-10): Rabbit testing for acute irritation response

Design Validation (User Testing)

- Usability testing: Healthcare professional evaluation under simulated clinical conditions

- Gloved operation: Validation with latex, nitrile, and surgical gloves

- Cleaning protocols: Hospital staff demonstration of cleaning procedures

Documentation from all testing activities becomes part of the Design History File (DHF) submitted to regulatory agencies. Plan 8-16 weeks for complete testing and documentation depending on device classification.

Cost Considerations

Medical grade membrane switches typically cost 40-80% more than equivalent commercial switches due to regulatory compliance, material requirements, and documentation overhead.

Cost Breakdown (Typical Medical Switch)

| Cost Component | Commercial Grade | Medical Grade |

|---|---|---|

| Base materials | Baseline | +20-30% (certified materials) |

| Manufacturing overhead | Standard | +15-25% (cleanroom, validation) |

| Testing & validation | Basic QC | +$2,000-5,000 (biocompat, validation) |

| Documentation | Minimal | +$1,000-3,000 (DHF, traceability) |

| Unit price (1000 pcs) | $8-15 | $12-25 |

Cost Optimization Strategies

- Standardize materials: Use pre-qualified material combinations across product lines

- Volume commitments: Annual purchase agreements reduce per-unit costs by 15-25%

- Design for manufacturability: Simpler designs with fewer custom features reduce tooling and assembly costs

- Supplier partnerships: Long-term relationships with ISO 13485 suppliers streamline qualification

While medical switches cost more upfront, the investment in compliance prevents costly recalls, regulatory delays, or patient safety incidents that can cost millions in remediation and reputation damage.

Frequently Asked Questions

What certifications are required for medical grade membrane switches?

Medical grade membrane switches require manufacturing in ISO 13485-certified facilities. Materials must meet biocompatibility standards (ISO 10993) appropriate to their contact classification. Manufacturers must also comply with FDA 21 CFR Part 820 (US) or EU Medical Device Regulation (MDR) depending on target markets. Complete documentation including Design History Files (DHF), material certificates, and lot traceability is essential for regulatory submissions.

Can membrane switches be sterilized in an autoclave?

Yes, but with limitations. Medical-grade polycarbonate overlays with high-temperature adhesives can withstand autoclave sterilization at 121°C for limited cycles (typically 10-50 cycles). However, repeated autoclaving causes adhesive degradation and material stress. For devices requiring frequent sterilization, consider removable/replaceable membrane overlays or alternative sterilization methods like ethylene oxide (EtO) or chemical disinfection.

What's the difference between medical grade and commercial grade membrane switches?

Medical grade switches use certified biocompatible materials, are manufactured in ISO 13485-certified facilities with full traceability, and include comprehensive documentation (DHF, material certificates). They feature superior chemical resistance to hospital disinfectants, higher IP ratings for fluid protection, and undergo rigorous biocompatibility and chemical resistance testing. Commercial switches lack these certifications and may use materials that fail cytotoxicity testing or degrade under medical cleaning protocols.

How long does it take to qualify a medical membrane switch supplier?

Supplier qualification for medical components typically takes 4-8 weeks for established ISO 13485-certified manufacturers with existing medical product lines. This includes facility audits, documentation review, first article inspection, and initial production validation. New suppliers without medical certification may require 6-12 months to establish compliant manufacturing processes and complete certification before qualification can begin.

What materials are best for medical membrane switches?

Polycarbonate (PC) is the preferred graphic overlay material for medical applications due to excellent chemical resistance, durability, and availability of biocompatibility-certified grades. Use medical-grade acrylic adhesives (3M 467MP/468MP series) with documented biocompatibility. Silver conductive inks provide reliable circuit performance. For critical applications, specify hard-coat polycarbonate with antimicrobial treatments for extended service life in high-cleaning environments.

Do all medical membrane switches require biocompatibility testing?

Biocompatibility requirements depend on patient contact classification per ISO 10993-1. Direct skin contact devices require cytotoxicity, sensitization, and irritation testing. Non-contact devices (environmental exposure only) typically require cytotoxicity testing at minimum. Implantable or blood-contact devices need comprehensive testing including systemic toxicity and hemocompatibility. Most membrane switches fall into non-contact or limited surface contact categories, requiring basic cytotoxicity validation.

References

- ISO 13485:2016 - Medical Devices - Quality Management Systems

- FDA 21 CFR Part 820 - Quality System Regulation

- ISO 10993 Series - Biological Evaluation of Medical Devices

- IEC 60601-1 - Medical Electrical Equipment Safety Standards

- EU Medical Device Regulation (MDR) 2017/745

- ISO 14971:2019 - Application of Risk Management to Medical Devices