Table of Contents

Quick Answer: Waterproof membrane switches use multi-layer sealing, specialized adhesives, and sealed construction to achieve IP ratings from IP65 (water jet protection) to IP68 (continuous immersion). Key design elements include complete perimeter sealing with 2-3mm adhesive borders, tail sealing or overmolded connectors, pressure equalization vents for submerged applications, and materials resistant to water ingress—enabling reliable operation in outdoor equipment, marine electronics, medical washdown environments, and industrial controls exposed to liquids.

Designing waterproof membrane switches requires understanding both the IP (Ingress Protection) rating system and the specific environmental challenges your device faces. Over 15 years at JASPER, I've engineered waterproof switches for applications ranging from poolside controls (IP68) to outdoor kiosks (IP65) and medical washdown equipment (IP66).

The difference between a switch that survives occasional splashes and one that operates reliably underwater for years comes down to systematic design principles. This guide provides the technical knowledge to specify, design, and validate waterproof membrane switches that meet your exact environmental protection requirements.

Understanding the IP Rating System

The IP (Ingress Protection) rating is an international standard (IEC 60529) that classifies the degree of protection provided by mechanical casings and electrical enclosures against intrusion of solid objects (first digit) and liquids (second digit).

For membrane switches, we focus primarily on the second digit—liquid ingress protection—though dust protection (first digit) is equally important for outdoor and industrial applications.

IP Rating Structure

An IP rating consists of two digits: IP[First Digit][Second Digit]

- First digit (0-6): Protection against solid objects and dust

- Second digit (0-9): Protection against liquids

For example, IP65 means:

- 6 = Dust-tight (complete protection against dust)

- 5 = Protected against water jets from any direction

In our manufacturing experience, the most commonly requested IP ratings for membrane switches are IP65, IP66, IP67, and IP68. Each serves distinct application requirements and involves different design complexities and costs.

IP Rating Breakdown for Membrane Switches

Here's a comprehensive breakdown of IP ratings relevant to membrane switch applications:

| IP Rating | Solid Protection (1st Digit) | Liquid Protection (2nd Digit) | Typical Applications |

|---|---|---|---|

| IP54 | Dust protected (limited ingress) | Splashing water protection | Indoor equipment, light exposure |

| IP65 | Dust-tight (no ingress) | Water jets (12.5 L/min) from any direction | Outdoor kiosks, industrial controls, kitchen equipment |

| IP66 | Dust-tight | Powerful water jets (100 L/min) | Marine equipment, washdown areas, deck controls |

| IP67 | Dust-tight | Temporary immersion (1m depth, 30 min) | Portable meters, handheld devices, outdoor sensors |

| IP68 | Dust-tight | Continuous immersion (depth/time specified by manufacturer) | Underwater controls, submersible pumps, pool equipment |

| IP69K | Dust-tight | High-pressure, high-temperature steam cleaning | Food processing, automotive manufacturing, dairy equipment |

Choosing the Right IP Rating

The appropriate IP rating depends on your specific environmental exposure:

- IP65: Sufficient for most outdoor and industrial applications where equipment faces rain, splashing, or cleaning with standard pressure hoses

- IP66/IP67: Required for marine environments, medical washdown areas, or equipment exposed to direct high-pressure cleaning

- IP68: Essential for submerged applications or devices that may be accidentally dropped in water

- IP69K: Specialized rating for food processing or applications requiring high-temperature steam sterilization

In our experience, approximately 60% of outdoor/industrial membrane switches specify IP65, 25% require IP66/IP67, and 15% need IP68 for submersible applications. Over-specifying (e.g., choosing IP68 when IP65 is sufficient) increases costs by 30-50% without functional benefit.

Waterproof Design Requirements

Achieving high IP ratings requires systematic attention to every potential water entry point in the membrane switch assembly.

Edge Sealing Techniques

The perimeter seal is the primary defense against water ingress. Proper edge sealing requires:

Adhesive Border Width

- IP65: Minimum 2mm continuous adhesive border

- IP67/IP68: 3-5mm adhesive border with dual-seal design

- No gaps or interruptions in the seal path

- Adhesive must bond to mounting surface with >1000 g/in peel strength

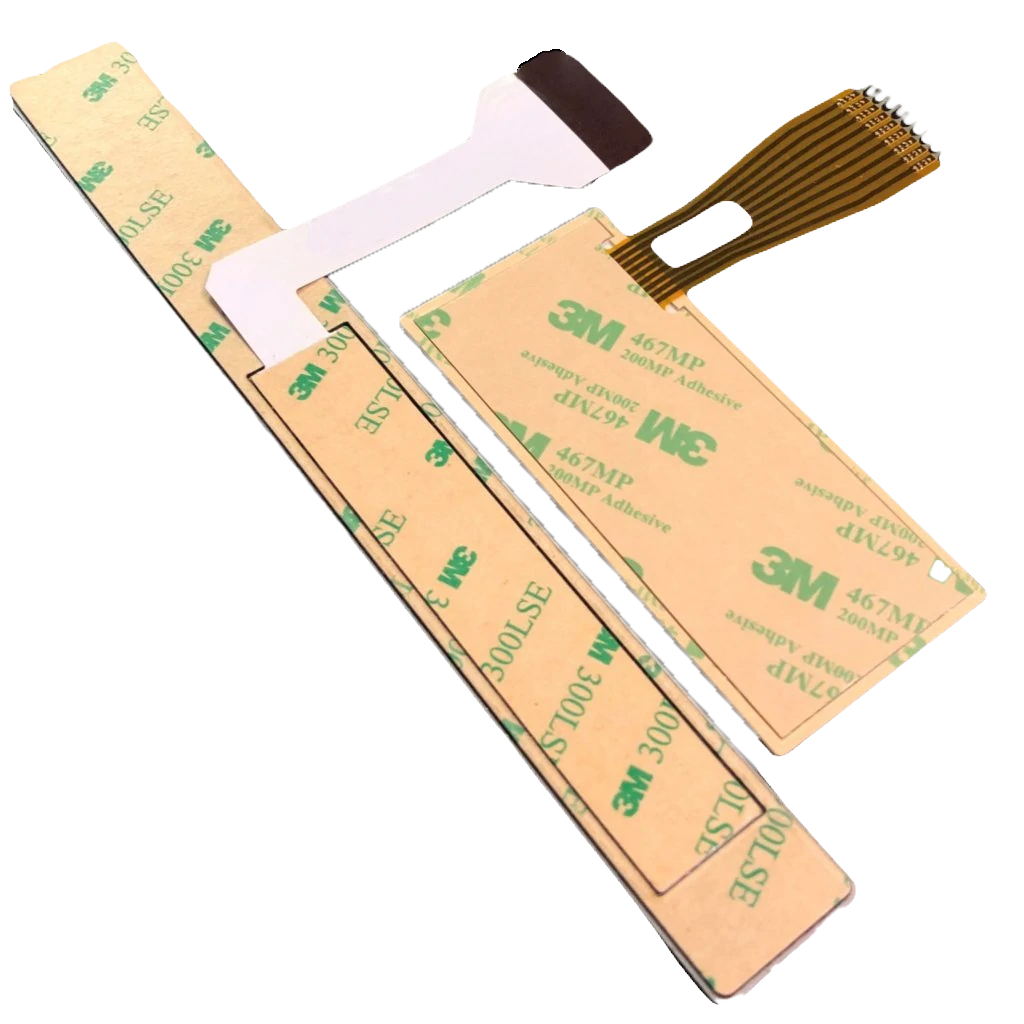

Sealing Adhesive Selection

- Acrylic foam adhesives (3M VHB): Excellent for IP65/IP66, conformable to irregular surfaces

- High-bond acrylic (3M 300LSE): Superior adhesion to low-surface-energy plastics

- Silicone gaskets: Best for IP68 applications, maintains seal under thermal cycling

Mounting Surface Preparation

- Surface must be clean, dry, and free from oils or contaminants

- Minimum surface energy: 38 dynes/cm (use surface preparation adhesion promoters if lower)

- Surface flatness: ±0.5mm across sealing area to prevent gaps

We've found that 80% of waterproofing failures result from inadequate surface preparation rather than switch design defects. Always provide detailed installation instructions emphasizing surface cleaning protocols.

Connector and Tail Protection

The connector tail is the most vulnerable point for water ingress. Protection strategies include:

Tail Sealing Options

- Epoxy potting: Encapsulate exposed conductors in waterproof epoxy compound (most common for IP67+)

- Heat-shrink tubing: Multi-layer heat-shrink with adhesive lining (suitable for IP65)

- Overmolded connectors: Custom injection-molded seal around tail-to-connector interface (premium solution for IP68)

- Sealed connector housings: Use IP67-rated connectors with mating seals (flexible cable applications)

Connector Location Considerations

- Position connector exit on underside or protected edge to prevent direct water contact

- Provide strain relief to prevent flex-induced seal cracking

- Include drip loops in cable routing to direct water away from connection points

For marine and underwater applications, we recommend overmolded connectors despite the 40-60% cost premium. In submersible pool equipment we've manufactured, overmolded tails showed zero failures over 5 years, while epoxy-potted alternatives experienced 3-5% seal failures requiring warranty replacements.

Pressure Equalization

Sealed enclosures face pressure differential challenges during temperature changes or altitude shifts. For IP67/IP68 applications, pressure equalization becomes critical:

Why Pressure Equalization Matters

- Temperature drop creates negative pressure (vacuum) that can draw water through microscopic gaps

- Altitude changes (e.g., shipping by air) create similar pressure differentials

- Repeated thermal cycling accelerates adhesive fatigue and seal degradation

Solutions for Pressure Management

- Gore-Tex vents: Hydrophobic membranes that allow air passage while blocking water (standard for IP67/IP68)

- Pressure equalization valves: One-way valves that release pressure buildup

- Conformal coating: Apply waterproof coating to circuit layers as secondary protection

Devices operating in extreme temperature environments (-40°C to +85°C) should incorporate pressure equalization vents as standard practice. We've measured pressure differentials exceeding 20 kPa in sealed outdoor enclosures during winter-to-summer transitions—sufficient to compromise standard adhesive seals.

Material Selection for Waterproofing

Material choices directly impact waterproofing effectiveness and long-term seal integrity.

Graphic Overlay Materials

Polycarbonate (PC) - Recommended for IP67/IP68

- Excellent dimensional stability in wet environments

- Does not absorb water (0.1-0.2% water absorption vs. 0.6% for polyester)

- Superior edge seal compatibility (smoother edge surface)

- Chemical resistance to saltwater, chlorinated water, oils

Polyester (PET) - Suitable for IP65

- Lower cost than polycarbonate

- Acceptable water resistance for non-immersion applications

- Slight edge curling over time with moisture exposure (impacts seal integrity)

For marine and underwater applications, we exclusively use polycarbonate. In accelerated aging tests (1000 hours at 85°C/85% RH), polycarbonate switches maintained IP68 ratings while polyester switches degraded to IP55 equivalent due to edge delamination.

Circuit Layer Protection

Even with perfect external sealing, secondary circuit protection adds reliability:

- Conformal coating: Spray or dip-coat circuits with acrylic, urethane, or silicone coating (25-125 microns thick)

- Encapsulated circuits: Laminate circuit layers between polyester films for complete isolation

- Corrosion-resistant inks: Silver-polymer composite inks resist oxidation in humid environments

Adhesive System Design

Multi-layer adhesive systems provide redundant sealing:

- Layer 1 (internal): Standard acrylic adhesive for component bonding

- Layer 2 (perimeter): High-bond acrylic or silicone for primary water seal

- Layer 3 (mounting): VHB foam or LSE adhesive for device attachment

This redundant approach ensures that even if the outer seal is compromised, internal seals prevent water from reaching critical circuits.

Testing and Validation Methods

IP rating claims must be validated through standardized testing per IEC 60529. At JASPER, we perform comprehensive waterproofing validation on all high-IP-rated switches.

Standard IP Testing Protocols

IP65 Testing (Water Jets)

- Test duration: 3 minutes per square meter (minimum 15 minutes)

- Water flow rate: 12.5 liters/minute

- Nozzle distance: 2.5-3 meters

- Test pressure: 30 kPa (0.3 bar)

- Pass criteria: No water ingress causing harmful effects

IP67 Testing (Temporary Immersion)

- Immersion depth: 1 meter (measured to top of enclosure)

- Test duration: 30 minutes

- Water temperature: Room temperature (15-35°C)

- Pass criteria: No water ingress that could cause damage

IP68 Testing (Continuous Immersion)

- Test parameters defined by manufacturer (typically 2-3 meters, continuous operation)

- Extended duration: 2-24 hours depending on application

- Functional testing: Device must operate normally during and after immersion

- Pass criteria: Zero water ingress, maintained functionality

Accelerated Life Testing

Standard IP testing validates momentary performance. Accelerated life testing predicts long-term reliability:

- Thermal cycling: -40°C to +85°C, 100+ cycles (tests seal integrity through expansion/contraction)

- UV exposure: 1000+ hours under UV-B lamps (validates outdoor graphic overlay and adhesive stability)

- Chemical resistance: Exposure to saltwater, chlorine, oils, detergents

- Mechanical stress: Vibration and shock testing while wet

In our experience, switches that pass accelerated life testing (equivalent to 5-7 years field exposure) show 95%+ survival rates in actual deployments. Switches validated only through basic IP testing experience 10-15% field failures within 3 years.

Quality Control Testing

Production-level testing ensures consistent waterproofing:

- 100% electrical testing: Verify circuit integrity (no shorts from moisture)

- Sample immersion testing: Random samples from each production batch undergo full IP testing

- Visual inspection: Check seal continuity, adhesive coverage, tail sealing quality

- Leak detection: Helium leak testing for critical IP68 applications (detects micro-leaks)

Common Waterproof Applications

Waterproof membrane switches serve diverse industries where moisture exposure is unavoidable:

Marine and Boating

- Boat control panels: IP66 minimum for deck-mounted controls, IP68 for submerged components

- Fish finders and navigation: IP67 for portable units, IP68 for permanently mounted displays

- Dock equipment: IP66 for above-waterline controls exposed to waves and spray

- Key challenges: Saltwater corrosion, constant moisture, thermal cycling, UV exposure

Outdoor Equipment

- Public kiosks: IP65 for rain protection, touchscreen overlays, vandal resistance

- Parking meters: IP67 for complete weather protection

- Outdoor ATMs: IP65 minimum, often IP66 for exposed locations

- Key challenges: Temperature extremes, direct sunlight, precipitation, dust

Industrial and Manufacturing

- Food processing controls: IP69K for steam cleaning environments

- Beverage equipment: IP66/IP67 for wet production areas

- Chemical processing: IP67 with chemical-resistant materials

- Key challenges: Aggressive chemicals, washdown procedures, contamination prevention

Medical and Laboratory

- Surgical equipment: IP67 for sterilization compatibility

- Lab instruments: IP65 for splash protection during sample processing

- Dental equipment: IP66 for patient area washdown

- Key challenges: Disinfectant compatibility, biocompatibility, frequent cleaning

Consumer Products

- Pool and spa controls: IP68 for submerged operation

- Outdoor appliances: IP65 for grills, outdoor refrigerators

- Fitness equipment: IP65 for sweat and cleaning spray protection

- Key challenges: Cost sensitivity, aesthetic requirements, consumer expectations

Design Best Practices

Based on 15 years of waterproof switch development, these practices maximize reliability:

Design Phase

- Specify IP rating early: Define requirements before schematic design to avoid costly redesigns

- Design for assembly: Ensure mounting surface is flat, accessible, and compatible with adhesive bonding

- Minimize penetrations: Each additional penetration (mounting hole, LED window) increases failure risk

- Plan for drainage: Orient device so water naturally drains away from seals

- Select proven materials: Use material combinations with documented waterproof performance

Prototyping Phase

- Test early and often: Validate waterproofing in functional prototypes, not just production units

- Real-world exposure: Field test prototypes in actual operating environments

- Thermal cycling: Test seal integrity through temperature extremes before production

- Document failures: Analyze any prototype failures to identify design weaknesses

Production Phase

- Implement process controls: Monitor adhesive application, cure times, seal inspection

- Qualify suppliers: Ensure material suppliers provide consistent, certified waterproof materials

- Sample testing: Random IP testing of production samples (1-5% depending on volume)

- Traceability: Maintain lot traceability for adhesives, coatings, and sealing materials

Installation Phase

- Clear instructions: Provide detailed installation procedures emphasizing surface prep and torque specs

- Installation verification: Include visual inspection checklist for installers

- Service accessibility: Design for seal replacement without complete disassembly

Common Design Mistakes to Avoid

- Insufficient adhesive border: Using less than 2mm seal width

- Sharp corners: 90° corners concentrate stress and cause seal failure—use 2mm+ radius corners

- Exposed circuit tails: Leaving conductors unprotected from moisture wicking

- Over-specifying: Designing for IP68 when IP65 is sufficient (adds 40-60% cost)

- Inadequate strain relief: Cable flexing causes seal cracking at connector interface

- Ignoring thermal expansion: Material mismatch causes seal gaps during temperature cycling

In our quality audits of failed waterproof switches, we found that 65% of failures stemmed from installation errors (improper surface prep, incorrect mounting), 25% from design flaws (inadequate sealing borders, material incompatibility), and only 10% from manufacturing defects. This emphasizes the importance of comprehensive installation documentation.

Frequently Asked Questions

What IP rating do I need for outdoor membrane switches?

For most outdoor applications, IP65 provides adequate protection against rain, splashing, and dust. IP65 protects against water jets from any direction, making it suitable for outdoor kiosks, parking meters, and equipment exposed to weather. If the device faces high-pressure washdown or frequent heavy rain exposure, consider IP66. For outdoor equipment that might be accidentally dropped in water or faces flooding, IP67 is recommended.

Can membrane switches be fully submersible?

Yes, membrane switches can achieve IP68 rating for continuous submersion. This requires complete perimeter sealing with 3-5mm adhesive borders, overmolded or fully potted connector tails, polycarbonate overlay materials, and pressure equalization vents to prevent seal failure from thermal cycling. Submersible switches successfully operate in pool controls, underwater sensors, and marine equipment. The specific immersion depth and duration must be defined during design and validated through testing.

How do you seal the connector tail on waterproof membrane switches?

Tail sealing methods include: 1) Epoxy potting—encapsulating exposed conductors in waterproof epoxy (most common for IP67+), 2) Heat-shrink tubing with adhesive lining (suitable for IP65), 3) Overmolded connectors with injection-molded seals (premium solution for IP68), and 4) IP67-rated sealed connectors with mating gaskets. For marine and underwater applications, overmolded connectors provide the most reliable long-term protection despite higher cost.

What materials are best for waterproof membrane switches?

Polycarbonate graphic overlays are strongly recommended for IP67/IP68 applications due to minimal water absorption (0.1-0.2%), excellent dimensional stability, and superior edge sealing. Use high-bond acrylic adhesives (3M 300LSE) or silicone gaskets for perimeter sealing. Circuit layers should have conformal coating (acrylic, urethane, or silicone) for secondary moisture protection. For marine applications, specify materials with saltwater and UV resistance.

How much does waterproofing add to membrane switch cost?

Waterproofing adds 20-30% cost for IP65, 40-60% for IP67, and 60-100% for IP68 compared to standard non-sealed switches. Cost increases come from specialized adhesives, tail sealing processes, conformal coating, waterproof testing, and premium materials. Overmolded connectors add $3-8 per unit. While waterproofing increases upfront costs, it prevents expensive field failures, warranty claims, and product recalls that can cost 10-50x the initial savings.

How do you test waterproof membrane switches?

Waterproof testing follows IEC 60529 standards. IP65 testing uses water jets (12.5 L/min at 30 kPa) for 15+ minutes. IP67 requires 30-minute immersion at 1-meter depth. IP68 testing uses extended immersion at manufacturer-specified depths (typically 2-3 meters for 2-24 hours). Accelerated life testing includes thermal cycling (-40°C to +85°C), UV exposure (1000+ hours), and chemical resistance testing. Production samples undergo random testing to ensure consistent waterproof performance.

References

- IEC 60529 - Degrees of Protection Provided by Enclosures (IP Code)

- ISO 20653 - Road Vehicles - Degrees of Protection (IP Code) - Protection of Electrical Equipment

- MIL-STD-810G - Environmental Engineering Considerations and Laboratory Tests

- NEMA 250 - Enclosures for Electrical Equipment (1000 Volts Maximum)

- ASTM D3359 - Standard Test Methods for Measuring Adhesion by Tape Test