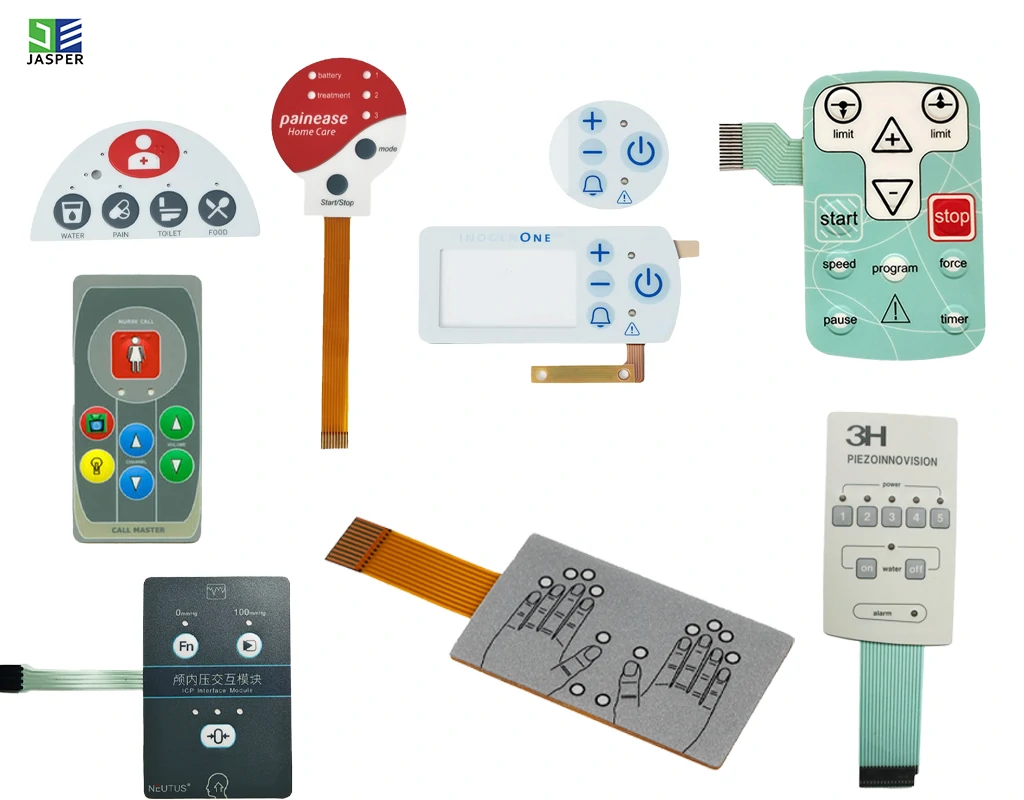

Custom Membrane Switch Manufacturer | ISO, Backlit

Time:

2025-10-27

We design and manufacture custom membrane switches for medical and industrial HMIs — tactile/non-tactile, LED/EL/LGF backlighting, EMI/ESD shielding, IP65–IP67 sealing, and ZIF/FFC connectors. Upload drawings to get a fast quote.

Capabilities at a Glance

- Form factors: flat or embossed keys; tactile (metal dome/polydome) & non-tactile

- Backlighting: LED, EL, LGF light guide; windows & indicators

- Materials: PET/PC overlays; silver/carbon inks; optional FPC/Cu circuits

- Adhesives: 3M 200MP family (e.g., 467MP/468MP) for overlay/rear bonding

- Connectors: ZIF/FFC tail with common pitches; custom pinouts

- Protection: IP65–IP67 sealing; EMI/ESD shielding; UV/chemical resistance

- Quality: ISO-based QMS, RoHS/REACH materials, reliability testing

Typical Stack-Up & Options

- Graphic overlay (PET/PC; textures, windows, color matching)

- Overlay adhesive (selective)

- Top circuit (silver/carbon; optional metal domes/polydomes)

- Spacer (normally-open separation)

- Bottom circuit (silver/carbon/FPC)

- Rear adhesive (3M 467MP/468MP)

Design note: Use 468MP (thicker) where better wet-out on textured powder-coat is needed; 467MP suits smoother, high-energy substrates. Always validate on your substrate.

Design Options & Materials

- Tactile feel: dome shape/diameter/actuation force; pillow vs rim emboss

- Backlighting: LED (bright, efficient) / EL (ultra-thin, even glow; needs inverter) / LGF (thin light guide)

- Optics: hard-coat, anti-glare/UV; clear/tinted windows

- Circuits: printed PET vs FPC; define tail pitch & length for ZIF spec

- Shielding: printed carbon ground or metallic foil for EMI/ESD

Environmental & IP Ratings

We design for dust/water ingress (gaskets, edge-sealing, venting) and UV/chemical exposure in outdoor/industrial conditions. Typical targets: IP65–IP67. See our Adhesives and Waterproof Design guides for details.

Electrical Interface (ZIF/FFC)

Define pin count, pitch (e.g., 0.5/1.0/1.27 mm), tail thickness for ZIF spec, and key matrix/commons. Provide the controller connector part number when available to avoid re-spins.

Quality, Compliance & Testing

- Regulatory: RoHS/REACH materials; ISO-based production; optional ISO 13485 for medical lines

- Mechanical: actuation life (typically millions of cycles), peel/shear, abrasion/UV

- Electrical: contact resistance, insulation, ESD robustness

- Documentation: PPAP on request; lot/material traceability

From Prototype to Production

- Rapid prototypes (functional, color-matched overlays)

- Panelization to improve yield and reduce cost

- Lead time & MOQ tuned to stack-up complexity and tooling

- Change control and engineering reviews at each phase

Industries & Applications

- Medical devices (cleanability, ISO 13485 option, backlit icons)

- Industrial controls (glove operability, EMI/ESD, IP sealing)

- Outdoor/marine (UV/salt-mist; reinforced edge sealing)

Internal Links

FAQ

What’s the difference between tactile and non-tactile designs?

Tactile versions use metal domes or polydomes to provide a click feel; non-tactile versions rely on audio/visual feedback and enable ultra-thin profiles.

How do I choose between LED, EL and LGF backlighting?

LED is bright and efficient; EL is ultra-thin and provides even glow but requires an inverter; LGF is thin and guides light to icons/logos.

Which adhesive should I specify?

Start with 3M 200MP family. 467MP suits smoother/high-energy substrates; 468MP (thicker) helps wet-out on textured/powder-coat surfaces. Validate on your substrate.

What tail pitch should I use for ZIF/FFC?

Common pitches: 0.5/1.0/1.27 mm. Match the connector on your controller; provide part number if possible.

Typical lead time and MOQ?

Depends on stack-up and tooling. Prototypes in weeks; production after DFM & first-article approval. See Lead Time & MOQ.

Relevant news