Backlighting Options for Membrane Switches (LED / EL / LGF) | JASPER

Time:

2025-10-31

This guide by JASPER explains three major backlighting solutions for membrane switches — LED, EL, and LGF — detailing their working principles, advantages, limitations, and design recommendations for achieving optimal brightness, thickness, power efficiency, and reliability in industrial and medical HMI applications.

Why Backlighting Matters

In applications where equipment operates in low light or critical conditions, operators must quickly locate controls. Effective backlighting not only enhances readability and usability but also contributes to branding through illuminated icons and color cues.

Three Common Backlighting Technologies

JASPER offers three proven backlighting methods — each with its own cost, thickness, and performance profile:

- LED Backlighting – High brightness, long lifetime, and color flexibility.

- EL (Electroluminescent) Backlighting – Ultra-thin and uniform glow, ideal for compact devices.

- LGF (Light Guide Film) Backlighting – Thin, evenly distributed lighting using edge-mounted LEDs.

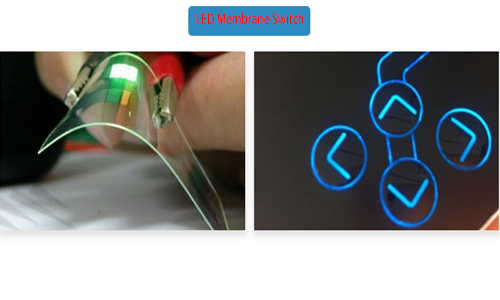

LED Backlighting

Light-Emitting Diodes (LEDs) are the most widely used method for backlighting membrane switches today. They offer excellent brightness, long service life, and wide color selection.

- Advantages: High brightness, long lifespan (50k+ hrs), customizable colors (RGB), low power.

- Limitations: Requires precise light diffusion and spacing; slightly increases total thickness.

- Best for: Industrial panels, outdoor controls, medical equipment.

EL Backlighting

Electroluminescent (EL) panels emit uniform light when driven by AC voltage. They are exceptionally thin (≤0.2 mm) and can cover large areas evenly.

- Advantages: Ultra-thin, uniform illumination, minimal heat.

- Limitations: Needs inverter, limited lifetime (~3–5k hrs), brightness declines over time.

- Best for: Compact devices or when even glow is required.

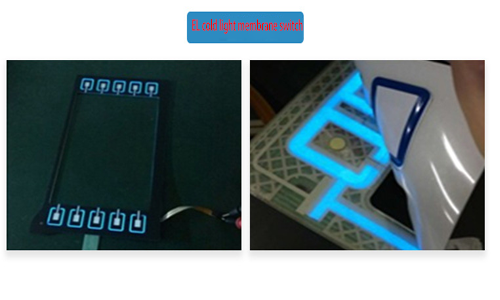

LGF (Light Guide Film) Backlighting

Light Guide Film (LGF) technology distributes light from edge-mounted LEDs through optical micro-patterns, achieving thin and even illumination with minimal energy consumption.

- Advantages: Thin (<0.4 mm), uniform lighting, flexible design geometry.

- Limitations: Slightly higher tooling cost, requires optical patterning.

- Best for: Devices demanding thin profile and multiple icon lighting zones.

Design Considerations for Backlighting

- Use diffusers and light-blocking inks to improve uniformity.

- Check thermal management for high-brightness LED designs.

- Consider IP rating sealing requirements; backlighting may affect venting.

- Ensure power budget and connector pinout accommodate illumination lines.

How Backlighting Affects Cost

Adding backlighting increases material and assembly costs by 10–25%, depending on technology and complexity. EL and LGF are more expensive than LED but may save space and assembly time. JASPER’s DFM team can optimize panel design and reduce cost through smart LED placement and optical simulation.

Choosing the Right Option

When selecting a backlight solution, balance brightness, uniformity, thickness, and lifetime requirements. For outdoor or high-brightness needs, choose LED. For compact, thin designs, EL or LGF may be more suitable. JASPER engineers can provide prototypes for evaluation before final production.

FAQ

Which backlight is brightest?

Which backlight is thinnest?

Can backlighting affect IP rating?

What is the lifetime difference?

Relevant news