Table of Contents

Quick Answer: Industrial control panel switches must withstand harsh factory environments including temperature extremes (-40°C to +85°C), vibration, dust, moisture, oils, and chemicals while providing reliable operation for 5-10 million actuations. Membrane switches are the preferred choice for 70% of industrial applications due to sealed construction (IP65-IP67), chemical resistance, tactile feedback with metal domes (250-450gf for gloved operation), clear graphics with backlighting, and competitive pricing ($8-25 per panel). Key selection criteria include environmental sealing, actuation force for gloved use, EMI/RFI shielding, safety certifications (UL, CE, ATEX for hazardous locations), and integration with PLCs and industrial protocols.

Industrial control panels are the command centers of modern manufacturing—controlling everything from assembly line robots to chemical processing systems. The switches that operators interact with must perform flawlessly under conditions that would destroy consumer-grade interfaces within weeks.

After 15 years at JASPER manufacturing control panel switches for automotive plants, food processing facilities, and heavy industry, I've learned that industrial switch selection requires balancing durability, usability, safety compliance, and cost. This guide provides systematic criteria to specify switches that deliver reliable performance in your specific industrial environment.

Industrial Environment Requirements

Industrial environments present unique challenges that distinguish them from commercial or consumer applications.

Physical Environment Challenges

Temperature Extremes

- Foundries and metalworking: Ambient temperatures regularly exceed 50°C near furnaces and casting operations

- Cold storage facilities: Control panels in freezer warehouses operate at -30°C to -40°C continuously

- Outdoor installations: Oil fields, mining equipment, agricultural machinery face -40°C to +85°C seasonal ranges

- Thermal cycling: Equipment near ovens or cooling systems experiences rapid temperature swings causing material stress

Vibration and Shock

- Heavy machinery: Presses, stamping equipment, and industrial mixers generate continuous vibration

- Mobile equipment: Forklifts, construction vehicles, agricultural machinery subject controls to constant shock

- Requirements: Switches must maintain electrical contact and structural integrity through vibration per IEC 60068-2-6 (10-150 Hz, 2g acceleration)

Contaminant Exposure

- Dust and particulates: Woodworking, mining, cement production generate heavy dust requiring IP65+ sealing

- Moisture and humidity: Food processing, beverage production, car washes involve frequent water exposure

- Oils and greases: Automotive manufacturing, machining operations coat equipment in cutting fluids and lubricants

- Chemicals: Chemical processing, pharmaceutical manufacturing expose panels to aggressive solvents and cleaners

Operator Considerations

Gloved Operation

- Safety gloves: Leather, Kevlar, or heavy cotton work gloves reduce tactile sensitivity by 60-80%

- Chemical protection: Thick nitrile or neoprene gloves in chemical handling require higher actuation forces

- Cold weather: Insulated winter gloves in outdoor applications need oversized button areas

- Design implications: Minimum button size 15mm, actuation force 250-450gf, definitive tactile feedback essential

Visual Conditions

- Poor lighting: Dimly lit factory floors, nighttime outdoor operations require backlit controls

- Bright sunlight: Outdoor equipment needs high-contrast graphics with anti-glare treatments

- Visibility distance: Machine operators may view panels from 2-3 meters requiring larger graphics (minimum 8mm text height)

Operational Demands

High Cycle Life

- Continuous operations: 24/7 manufacturing requires switches rated for 5-10 million actuations minimum

- Repetitive tasks: Assembly line operators may press the same button hundreds of times per shift

- Cost of downtime: Production line downtime costs $5,000-50,000 per hour—switch failures are unacceptable

Reliability Requirements

- MTBF expectations: 100,000+ hours mean time between failures for critical controls

- Mission-critical systems: Emergency stops, safety interlocks, process controls cannot fail

- Maintenance windows: Scheduled maintenance only during quarterly shutdowns—field failures require immediate response

Types of Industrial Control Switches

Membrane Switches

Membrane switches are the dominant choice for industrial control panels, accounting for approximately 70% of installations due to their sealed construction, durability, and flexibility.

Advantages for Industrial Applications:

- Environmental sealing: IP65-IP68 ratings protect against dust, water, oils, and chemicals

- Customizable graphics: Full-color printing integrates branding, instructions, and color-coding directly on the switch

- Tactile feedback: Metal dome construction provides definitive actuation confirmation for gloved operation

- Flat profile: Smooth surface resists contamination buildup and simplifies cleaning

- Cost-effective: Lower per-unit cost than mechanical switches, especially for multi-button panels

- Design flexibility: Custom shapes, sizes, and layouts accommodate unique panel requirements

Industrial Membrane Switch Specifications:

- Overlay material: Polycarbonate (0.250-0.375mm) with hard coat for chemical resistance and abrasion

- Actuation force: 300-450gf for reliable gloved operation (vs 150-250gf for consumer applications)

- Tactile domes: Stainless steel, 10-12mm diameter for larger button areas and positive feedback

- Life cycle: 5-10 million actuations (some applications specify 20+ million)

- Temperature rating: -40°C to +85°C operating range standard

- IP rating: IP65 minimum, IP67 for washdown or outdoor applications

Limitations:

- Limited force feedback compared to mechanical switches (may not suit applications requiring 500gf+ actuation)

- Graphic overlay can fade with extreme UV exposure (mitigated with UV-resistant inks and coatings)

- Cannot be field-repaired—entire panel replacement required for failures

Mechanical Switches

Mechanical switches (pushbuttons, toggle switches, rotary selectors) remain preferred for applications requiring extreme durability, high actuation forces, or field serviceability.

When to Choose Mechanical Switches:

- Extreme force requirements: Safety interlocks, emergency stops requiring 500-1500gf deliberate actuation

- Ultra-high cycle life: Applications exceeding 10 million actuations (some mechanical switches rated for 50+ million)

- Field serviceability: Individual switch replacement without panel replacement

- Harsh chemical exposure: Stainless steel or chemical-resistant housings for extreme environments

- Visual/audible confirmation: Illuminated indicators, distinct mechanical click for positive feedback

Disadvantages:

- Higher cost per switch ($5-25 each vs $8-25 for complete membrane panel)

- Difficulty achieving IP67+ sealing (individual switch seals can fail)

- Complex installation requiring panel cutouts, wiring, and mounting hardware

- Contamination buildup in gaps around switches

- Limited graphic integration (requires separate labels or legends)

Capacitive Touch Interfaces

Capacitive touch technology is gaining adoption in industrial applications where flat, sealed surfaces and modern aesthetics are valued.

Industrial Capacitive Touch Advantages:

- Completely sealed: Glass or polycarbonate surface with no mechanical penetrations achieves IP68+ easily

- Unlimited graphics: Digital displays allow dynamic interfaces, multi-language support, and real-time data

- No moving parts: Eliminates mechanical wear—theoretically unlimited cycle life

- Easy cleaning: Smooth surface with no crevices simplifies sanitation

- Modern appearance: Premium aesthetic for customer-facing equipment or showcase installations

Industrial Capacitive Touch Challenges:

- Glove compatibility: Standard capacitive touch doesn't work with non-conductive gloves—requires special "industrial touch" technology or thick glove modes

- No tactile feedback: Lacks physical confirmation—requires audible/visual feedback which may be insufficient in noisy environments

- Accidental activation: Water, debris, or leaning on panel can trigger false inputs

- Higher cost: 2-5x more expensive than membrane switches for equivalent functionality

- Complex integration: Requires touchscreen controller, software development, and system integration

- Temperature sensitivity: Performance degrades at temperature extremes (especially <-20°C)

Recommendation: Capacitive touch suits clean-room environments, food processing (easy sanitation), and applications where operators remove gloves. For typical heavy industrial environments with gloved operators, membrane switches remain more practical.

Critical Features for Industrial Applications

Tactile Feedback Design

Proper tactile design is essential for industrial applications where operators cannot rely solely on visual confirmation.

Actuation Force Selection:

| Application Type | Recommended Force | Rationale |

|---|---|---|

| Light-duty, bare hands | 150-250gf | Standard tactile response for indoor control rooms |

| Standard gloved operation | 300-350gf | Most common industrial specification—leather, cotton, or thin nitrile gloves |

| Heavy gloves, vibration | 400-450gf | Chemical protection gloves, winter gloves, high-vibration environments |

| Emergency stops, critical controls | 500-1500gf (mechanical) | Deliberate activation to prevent accidental engagement |

Button Size and Spacing:

- Minimum button size: 15mm diameter for gloved operation (vs 10mm for bare fingers)

- Critical controls: 20-25mm diameter for emergency stops and frequently-used functions

- Button spacing: Minimum 5mm edge-to-edge to prevent accidental adjacent button presses

- Travel distance: 0.4-0.6mm actuation travel for definitive mechanical feedback through gloves

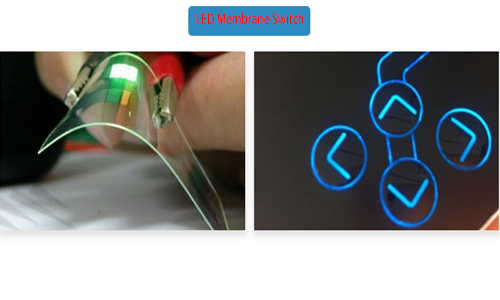

Backlighting and Visibility

Industrial environments often have poor or variable lighting conditions requiring integrated illumination.

LED Backlighting Options:

- Edge-lit LEDs: LEDs mounted on circuit edge illuminate entire panel through light guide—uniform illumination, lower cost

- Individual button LEDs: Dedicated LED per button for status indication—higher cost, enables per-button colors

- RGB LEDs: Multi-color capability for status indication (green=ready, yellow=warning, red=alarm)

- Brightness: Adjustable 10-1000 nits for operation from dark night shifts to direct sunlight

Graphic Design for Industrial:

- High contrast: Dark text/icons on light background or light on dark for maximum legibility

- Text size: Minimum 8mm character height for 2-3 meter viewing distance

- Color coding: Follow ISO 9355 and ANSI Z535 standards (red=stop, green=start, yellow=caution)

- Pictograms: Universal symbols reduce language barriers in multinational facilities

- Anti-glare: Matte or textured finishes reduce reflections under bright overhead lighting

EMI/RFI Shielding

Industrial environments contain high electromagnetic interference from motors, VFDs, welders, and RF equipment. Switches must not interfere with or be susceptible to EMI/RFI.

Shielding Methods:

- Conductive inks: Silver-filled or carbon-filled circuit traces provide inherent shielding

- Shielding layers: Metallized polyester film (aluminum or copper) between overlay and circuit

- Grounded construction: Shield layer connected to equipment ground through mounting hardware

- Cable shielding: Shielded ribbon cables or twisted-pair construction with drain wires

EMC Compliance:

- Emission standards: FCC Part 15 Class A (industrial), EN 55011 (European industrial equipment)

- Immunity standards: IEC 61000-4 series (ESD, radiated fields, electrical fast transients, surge)

- Testing levels: Industrial equipment typically requires Level 3 or Level 4 immunity (highest severity)

Environmental Protection Standards

IP Rating Selection

IP (Ingress Protection) ratings define the level of protection against solid and liquid ingress. Industrial control panels typically require IP65 minimum, with IP66-IP68 for demanding applications.

Industrial IP Rating Guide:

| IP Rating | Protection Level | Typical Industrial Applications |

|---|---|---|

| IP54 | Dust protected, splash resistant | Indoor control rooms, clean manufacturing areas |

| IP65 | Dust-tight, water jet resistant | General industrial, outdoor equipment, light washdown (most common specification) |

| IP66 | Dust-tight, powerful water jet | Food processing, beverage production, heavy washdown areas |

| IP67 | Dust-tight, temporary immersion | Marine equipment, outdoor mobile machinery, flood-prone areas |

| IP69K | Dust-tight, high-pressure high-temp | Food processing, dairy, pharmaceutical (steam cleaning) |

NEMA Enclosure Ratings

In North America, NEMA ratings are commonly specified instead of or in addition to IP ratings:

- NEMA 4/4X: Equivalent to IP66—weather-resistant, hose-down protection (4X adds corrosion resistance)

- NEMA 12: Indoor use, protection against dust, dripping liquids, light splashing

- NEMA 13: Indoor use, dust, spraying water, oil, and non-corrosive coolants

Chemical Resistance Requirements

Specify material compatibility with chemicals present in your environment:

- Automotive/machining: Cutting oils, hydraulic fluids, gasoline, diesel

- Food processing: Cleaning agents (alkaline, acidic), sanitizers (chlorine, quaternary ammonium)

- Chemical processing: Specific chemical exposure per MSDS—material testing required

- Standard industrial: Isopropyl alcohol, mineral spirits, general-purpose cleaners

Polycarbonate overlays with appropriate surface treatments provide broad chemical resistance suitable for most industrial environments. For extreme chemical exposure, consult material compatibility charts or conduct accelerated exposure testing.

Safety and Compliance Requirements

Safety Standards and Certifications

UL/CSA Certification (North America)

- UL 508: Industrial control equipment standard

- UL 61010: Safety requirements for electrical equipment for measurement, control, and laboratory use

- CSA C22.2: Canadian electrical equipment standards (often combined with UL as UL/CSA)

CE Marking (European Union)

- Low Voltage Directive (LVD): Electrical safety for equipment 50-1000V AC or 75-1500V DC

- EMC Directive: Electromagnetic compatibility requirements

- Machinery Directive: Safety requirements for machinery and control systems

IEC Standards (International)

- IEC 61010: Safety requirements for electrical equipment (harmonized with UL 61010)

- IEC 60204: Safety of machinery - electrical equipment of machines

- IEC 60947: Low-voltage switchgear and controlgear

Hazardous Location Classifications

Equipment used in explosive atmospheres requires special certification:

ATEX (Europe)

- Zone 1/21: Areas where explosive atmosphere present occasionally during normal operation

- Zone 2/22: Areas where explosive atmosphere unlikely or only for short periods

- Requirements: Intrinsically safe design, energy limitation, ignition source elimination

NEC/CEC Classifications (North America)

- Class I Division 1: Flammable gases/vapors present continuously or frequently

- Class II Division 1: Combustible dust present continuously or frequently

- Class III: Easily ignitable fibers or flyings

Membrane switches for hazardous locations require certification from accredited bodies (CSA, UL, FM Approvals for North America; ATEX notified bodies for Europe).

Functional Safety (Safety-Critical Applications)

Safety-critical applications (emergency stops, safety interlocks) may require functional safety compliance:

- ISO 13849 (Machinery Safety): Defines Performance Levels (PLa to PLe) for safety-related control systems

- IEC 61508 (Functional Safety): Safety Integrity Levels (SIL 1 to SIL 4) for electrical/electronic systems

- Requirements: Fault detection, redundancy, proven-in-use components, systematic failure prevention

While membrane switches themselves aren't typically SIL-rated components, they can be integrated into SIL-rated safety systems with proper design (redundant switches, diagnostics, etc.).

Industry-Specific Applications

Automotive Manufacturing

- Assembly line controls: IP65, 350gf tactile, 0.250mm PC, hard coat, -10°C to +50°C, LED backlighting

- Robot teach pendants: IP67, rubber overmold, ergonomic handheld, emergency stop button

- Paint booth controls: ATEX Zone 2 certified, sealed construction, glove-compatible

Food and Beverage Processing

- Production line HMI: IP66/IP69K, 0.375mm PC, antimicrobial coating, chemical-resistant, smooth surface for cleaning

- Packaging equipment: IP65, multi-language graphics, color-coded zones, sanitary design

- Temperature control: Washdown-compatible, -20°C to +60°C rating for cold storage to cooking areas

Oil and Gas

- Wellhead controls: IP67, -40°C to +85°C, UV-resistant, stainless steel backer, Class I Div 2 when required

- Pipeline monitoring: Solar-powered, low-power LED indicators, extreme weather resistance

- Refinery control stations: ATEX/IECEx certified, chemical-resistant, high-visibility graphics

Pharmaceutical Manufacturing

- Clean room controls: IP65, smooth surfaces, antimicrobial treatment, low particulate generation

- Process equipment: GMP-compliant materials, 21 CFR Part 11 audit trail integration, validation documentation

- Packaging lines: IP66, high-speed operation compatibility, batch number integration

Heavy Equipment and Construction

- Crane controls: IP67, vibration-resistant, large buttons, emergency stop, -30°C to +70°C

- Excavator panels: Outdoor UV protection, glove-friendly, shock-resistant mounting

- Generator controls: Ignition-protected, weather-sealed, long cable runs with shielding

Selection Framework

Use this systematic approach to specify industrial control panel switches:

Step 1: Environmental Assessment

- ☐ Operating temperature range (ambient and panel surface temperature)

- ☐ Humidity exposure (continuous, intermittent, condensing)

- ☐ Chemical exposure (list specific chemicals and concentrations)

- ☐ Dust/particulate level (clean room to heavy industrial)

- ☐ Water exposure (none, splash, washdown, immersion)

- ☐ UV exposure (indoor, indirect sunlight, direct outdoor)

- ☐ Vibration/shock levels (stationary, mobile equipment, high-vibration)

Step 2: Operational Requirements

- ☐ Operator glove type and thickness

- ☐ Viewing distance and lighting conditions

- ☐ Expected cycle life (actuations per day × service years)

- ☐ Number of buttons/functions required

- ☐ Backlighting requirements (yes/no, color, adjustable)

- ☐ Status indicators needed (LEDs, multi-color)

- ☐ Mounting method (surface mount, panel cutout, hinged door)

Step 3: Compliance and Safety

- ☐ Geographic markets (determines UL/CSA, CE, other certifications)

- ☐ Hazardous location classification (if applicable)

- ☐ Industry-specific standards (FDA, GMP, automotive, food safety)

- ☐ EMI/RFI requirements

- ☐ Safety functions (emergency stops, safety interlocks)

- ☐ Functional safety levels (SIL, Performance Level if applicable)

Step 4: Specification Summary

Based on assessments above, compile specifications:

| Specification | Recommended Value |

|---|---|

| Switch Type | Membrane / Mechanical / Capacitive Touch |

| Overlay Material | Polycarbonate 0.250mm with hard coat (typical) |

| Actuation Force | 300-350gf (gloved), 400-450gf (heavy gloves) |

| IP Rating | IP65 (standard), IP66/IP67 (washdown/outdoor) |

| Temperature Range | -40°C to +85°C (outdoor/extreme), -20°C to +60°C (indoor) |

| Life Cycle | 5 million minimum, 10+ million preferred |

| Backlighting | LED (white or RGB), adjustable brightness |

| Certifications | UL/CSA, CE (minimum), ATEX/IECEx if hazardous location |

Step 5: Supplier Evaluation

- Request samples for gloved operation testing in actual environment

- Verify certifications and compliance documentation

- Review quality control procedures and testing capabilities

- Evaluate lead times, MOQs, and scalability for production volumes

- Assess technical support and engineering assistance availability

Frequently Asked Questions

What IP rating do I need for industrial control panels?

Most industrial applications require IP65 minimum, providing dust-tight sealing and protection against water jets from any direction. Choose IP66 for food processing or heavy washdown environments with high-pressure cleaning. Select IP67 for outdoor mobile equipment or applications with potential temporary water immersion. Indoor control rooms in clean environments may use IP54. Always consider the harshest conditions the panel will encounter, not just typical operating conditions.

What actuation force is needed for gloved operation?

Standard work gloves (leather, cotton, thin nitrile) require 300-350gf actuation force for reliable tactile feedback. Heavy chemical protection gloves or thick winter gloves need 400-450gf. Button size should be minimum 15mm diameter (vs 10mm for bare finger operation) with 5mm spacing between buttons to prevent accidental adjacent activations. Metal dome tactile switches are strongly preferred over non-tactile for gloved applications.

Are membrane switches better than mechanical switches for industrial applications?

Membrane switches are preferred for 70% of industrial applications due to superior environmental sealing (IP65-IP68), lower cost, custom graphics integration, and flat contamination-resistant surfaces. Choose mechanical switches when you need: 1) actuation forces >500gf for deliberate activation (emergency stops), 2) field serviceability with individual switch replacement, 3) ultra-high cycle life (20+ million actuations), or 4) extreme chemical environments requiring stainless steel construction. Many panels use both—membrane switches for standard controls with mechanical emergency stop buttons.

What certifications are required for industrial control panels?

North American markets typically require UL 508 or UL 61010 certification plus CSA approval. European markets require CE marking demonstrating compliance with Low Voltage Directive, EMC Directive, and Machinery Directive. Hazardous location applications need ATEX (Europe) or Class/Division certifications (North America) from accredited bodies. Industry-specific requirements may include FDA (pharmaceutical/medical), GMP compliance (food/pharma), or automotive quality standards (IATF 16949). Consult your target markets and applications early in design to ensure proper certification path.

How long should industrial membrane switches last?

Industrial membrane switches should be rated for minimum 5 million actuations, with 10+ million preferred for continuous operations. For 24/7 manufacturing running 3 shifts with 100 button presses per shift, 5 million cycles provides approximately 45 years of service life—far exceeding typical equipment lifespan. In practice, environmental factors (temperature cycling, chemical exposure, UV degradation) often limit service life to 5-10 years before cosmetic or seal degradation necessitates replacement. High-quality industrial switches from reputable manufacturers typically exceed their rated cycle life in field applications.

Can I use capacitive touch instead of membrane switches in industrial applications?

Capacitive touch can work in specific industrial applications but has significant limitations. It struggles with thick non-conductive gloves (standard work gloves), provides no tactile feedback (problematic in noisy environments), experiences false activation from water or debris, and costs 2-5x more than membrane switches. Capacitive touch suits: 1) clean room environments where operators can remove gloves, 2) food processing applications prioritizing easy sanitation, 3) applications requiring dynamic displays or multi-language interfaces. For typical heavy industrial environments with gloved operators, tactile membrane switches remain more reliable and cost-effective.

References

- IEC 60529 - Degrees of Protection Provided by Enclosures (IP Code)

- NEMA 250 - Enclosures for Electrical Equipment

- IEC 60204 - Safety of Machinery - Electrical Equipment of Machines

- ISO 13849 - Safety of Machinery - Safety-Related Parts of Control Systems

- ANSI Z535 - Safety Colors, Signs, Symbols, and Tags

- UL 508 - Industrial Control Equipment