Graphic Overlay Materials and Printing Methods for Membrane Switches: Complete Guide

Time:

2025-12-18

Expert guide to membrane switch overlay materials (polyester, polycarbonate) and printing methods (screen, digital) covering durability, surface finishes, and cost optimization.

Table of Contents

- Introduction

- Graphic Overlay Material Options

- Material Properties and Selection Criteria

- Printing Technologies Overview

- Screen Printing Methods

- Digital Printing Technologies

- Surface Finishes and Textures

- Durability and Wear Resistance

- Color Management and Consistency

- Embossing and Tactile Features

- Cost Optimization Strategies

- Quality Control and Testing

- Frequently Asked Questions

- Conclusion

Quick Answer: Graphic overlay materials for membrane switches primarily include polyester (PET, 0.125-0.25mm thickness, economical $0.80-2.50 per square foot, excellent chemical resistance, good outdoor durability), polycarbonate (PC, 0.25-0.50mm, premium $2.00-4.50 per square foot, superior impact resistance, flame retardant options), and specialty films—printed via screen printing (traditional method, vibrant colors, 1,000+ unit volumes economical) or digital printing (UV-curable or solvent inks, full-color capability, prototype-friendly low setup costs), finished with matte, glossy, or textured surfaces (anti-glare, anti-fingerprint treatments), and validated through abrasion testing (100,000+ cycles per ASTM D1044), chemical resistance testing, and UV aging confirming long-term appearance retention.

The graphic overlay represents the visible user-facing layer of membrane switches—the aesthetic and functional interface communicating brand identity, providing operational information, protecting underlying components, and withstanding environmental exposure throughout product life. Superior overlay design combines attractive appearance (professional graphics, brand-aligned colors, clear readable legends), functional durability (abrasion resistance surviving millions of actuations, chemical resistance withstanding cleaning agents, UV stability maintaining appearance outdoors), appropriate tactile characteristics (surface texture affecting finger grip and feel), and manufacturing practicality (materials and printing methods supporting cost-effective production at required volumes).

As a membrane switch manufacturer with over 15 years of experience at JASPER, I've observed how overlay material and printing selections profoundly impact product success and customer satisfaction. A medical device manufacturer initially specified glossy polycarbonate overlay for diagnostic equipment—attractive showroom appearance but field usage revealed severe fingerprint smudging, glare under clinical lighting, and user complaints about visibility. Switching to matte anti-glare polyester with anti-fingerprint coating improved usability dramatically while reducing material cost $0.85 per switch—users specifically praised improved readability in reviews. Conversely, an outdoor equipment builder selected economy polyester with solvent-based printing to minimize cost—within 18 months, field units exhibited severe UV fading, graphic degradation, and unprofessional appearance. Upgrading to UV-stabilized polyester with UV-curable inks added $1.20 per unit but eliminated fading complaints and preserved brand image throughout 5-year outdoor exposure.

This guide examines graphic overlay materials, material properties and selection criteria, printing technologies, surface finishes, durability optimization, color management, and cost-performance trade-offs ensuring overlay specifications deliver excellent appearance, functionality, and longevity matching application requirements and budget constraints.

Graphic Overlay Material Options

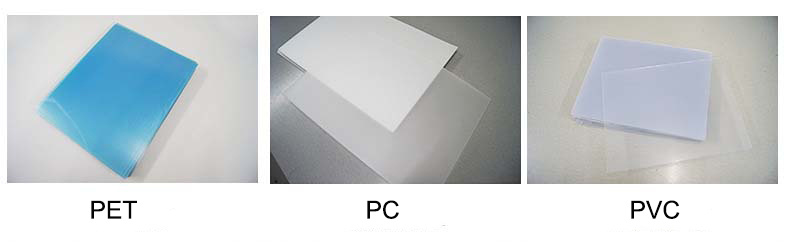

Understanding overlay material characteristics enables informed selection matching application requirements, environmental exposure, and cost constraints.

Polyester (PET) Films

Material Characteristics: Polyester (polyethylene terephthalate, PET) represents most common membrane switch overlay material offering excellent balance of performance, durability, and cost. Available thicknesses 0.075mm (3 mil), 0.125mm (5 mil, most common), 0.175mm (7 mil), 0.25mm (10 mil). Standard polyester provides good chemical resistance (resistant to alcohols, mild acids/bases, many solvents), excellent dimensional stability (minimal moisture absorption, low thermal expansion coefficient), superior outdoor weathering (UV-stabilized grades withstand years of sunlight exposure without significant degradation), and economical cost ($0.80-2.50 per square foot depending on thickness, finish, and volume). Polyester suits majority of membrane switch applications—indoor/outdoor equipment, industrial controls, consumer electronics, medical devices—where balanced performance and cost optimization desired.

Specialty Polyester Grades: Hard-coated polyester incorporates abrasion-resistant surface layer (typically silica or silicone-based coating) improving scratch and wear resistance 2-5× versus uncoated polyester—ideal for high-wear applications (public access terminals, industrial equipment, portable devices subject to abrasion). UV-stabilized polyester formulations resist degradation from prolonged sunlight exposure—outdoor equipment, automotive, marine applications. Matte-finish polyester provides anti-glare surface reducing reflections under bright lighting—medical devices, outdoor equipment, applications in bright environments. Textured polyester offers tactile differentiation and fingerprint resistance—consumer electronics, touch-heavy interfaces. Specialty grades cost premium 20-60% versus standard polyester justified when specific properties required.

Polycarbonate (PC) Films

Material Characteristics: Polycarbonate offers superior impact resistance and specialty properties commanding premium cost. Standard thicknesses 0.25mm (10 mil), 0.375mm (15 mil), 0.50mm (20 mil). Polycarbonate advantages include exceptional impact resistance (virtually unbreakable under normal conditions—ideal for harsh-environment or vandal-resistant applications), flame retardant grades (UL94 V-0 or V-2 ratings for applications requiring flammability certification), excellent clarity and appearance (high gloss finish creating premium aesthetic), and good forming characteristics (thermoforming complex shapes for 3D overlays). Cost ranges $2.00-4.50 per square foot—substantially higher than polyester. Polycarbonate limitations include poorer chemical resistance (attacked by many solvents, alcohols, and cleaning chemicals—concern for medical or frequently-cleaned applications), scratching susceptibility (softer surface scratches more easily than hard-coated polyester), and potential UV yellowing (standard grades yellow under prolonged sunlight—UV-stabilized formulations address but add cost).

Application Suitability: Polycarbonate optimal for applications requiring impact resistance (portable equipment subject to drops, harsh industrial environments, public access devices requiring vandal resistance), flame retardant certification (medical devices, aviation, electrical equipment), or premium appearance (high-end consumer electronics, automotive luxury applications). However, polyester generally preferred when impact resistance unnecessary and chemical/abrasion resistance valued—industrial equipment frequently cleaned, medical devices disinfected regularly, outdoor applications demanding UV stability. Cost-benefit analysis weighs polycarbonate premium against genuine requirement for impact/flame properties versus polyester adequate performance at lower cost.

Specialty Films and Alternatives

Acrylic Films: Cast acrylic overlays provide ultimate clarity, hardness, and weathering resistance—premium aesthetic and extreme durability. However, brittleness (cracks under impact), high cost ($5-10+ per square foot), and limited availability restrict to specialized applications justifying investment (luxury products, architectural applications, permanent outdoor installations). Rarely specified for typical membrane switches—polycarbonate or hard-coated polyester delivers adequate performance at fraction of cost.

Vinyl Films: Calendered or cast vinyl offers low cost ($0.40-1.50 per square foot) and good conformability (complex curves, 3D forming). However, limited durability (scratches easily, UV degradation), dimensional instability (moisture absorption, thermal expansion), and professional appearance concerns limit vinyl to economy applications, temporary products, or decorative overlays not subjected to abrasion or environmental stress. Polyester preferred for professional durable products despite modest cost premium delivering far superior longevity and appearance retention.

Material Properties and Selection Criteria

Systematic material selection considers multiple properties ensuring overlay performance meets application demands throughout product life.

Chemical Resistance Requirements

Polyester Chemical Compatibility: Polyester resists wide range of chemicals making ideal for frequently-cleaned applications. Excellent resistance to alcohols (isopropanol, ethanol—common disinfectants), dilute acids and bases (pH 3-11 range typical), water and humidity, oils and greases, and mild solvents. Limited resistance to strong acids/bases (concentrated sulfuric acid, sodium hydroxide attack polyester), ketones (MEK, acetone dissolve polyester), and aromatic solvents (toluene, xylene). Polyester suits medical devices (alcohol disinfection), food processing equipment (sanitizer compatibility), industrial controls (chemical exposure), and general commercial applications cleaned with standard agents.

Polycarbonate Chemical Limitations: Polycarbonate exhibits poorer chemical resistance—attacked by alcohols (isopropanol causes stress cracking), many solvents (ketones, aromatics, chlorinated solvents), ammonia-based cleaners, and some commercial disinfectants. Applications requiring frequent alcohol disinfection (medical devices) or exposure to harsh chemicals (industrial processes) better served by polyester despite polycarbonate impact advantages. Chemical compatibility testing validates material selection—expose sample to application-specific chemicals at expected concentrations and temperatures, evaluate surface appearance, mechanical properties, dimensional stability confirming adequate resistance.

Abrasion and Wear Resistance

Abrasion Testing Standards: ASTM D1044 Taber abraser test quantifies wear resistance—rotating abrasive wheels under specified load cycle across overlay surface, haze increase or weight loss after defined cycles (typically 100, 500, 1,000, 5,000 cycles) indicates wear susceptibility. Standard polyester exhibits moderate abrasion resistance (visible wear after 1,000-5,000 cycles), hard-coated polyester achieves 5,000-25,000+ cycles before significant wear, polycarbonate shows 500-3,000 cycles (softer surface wears faster than polyester). High-wear applications—public access terminals, industrial equipment with frequent button actuation, portable devices subject to abrasive contact—benefit from hard-coated polyester delivering extended appearance retention versus standard films.

Temperature and Environmental Stability

Operating Temperature Ranges: Polyester operates -40 to +150°C (brief exposure to +200°C) covering vast majority of applications including automotive engine compartments, outdoor winter conditions, and industrial high-temperature environments. Polycarbonate operates -40 to +120°C—adequate for most applications but less margin than polyester for extreme heat. Vinyl limited to -20 to +70°C—inadequate for demanding temperature exposure. Temperature selection considers both operational environment and manufacturing processes (forming, adhesive bonding temperatures must remain within material limits). UV stability critical for outdoor applications—UV-stabilized polyester maintains appearance and properties through years of sunlight exposure, standard polycarbonate yellows requiring UV-stabilized grades adding cost, vinyl degrades rapidly outdoors limiting to indoor protected installations.

Printing Technologies Overview

Multiple printing technologies suit membrane switch graphic overlay production—each offering distinct capabilities, cost structures, and application suitability.

Technology Comparison

Screen Printing: Traditional membrane switch printing method uses mesh screen transferring ink through open areas onto substrate. Advantages include vibrant opaque colors (excellent opacity even on dark substrates), thick ink deposits (durable wear-resistant graphics), proven reliability (billions of successful membrane switches produced via screen printing), and economical high-volume production (low per-unit cost at quantities >1,000 units). Limitations include setup costs ($150-300 per screen color requiring minimum volumes 500-1,000+ units for economic justification), lead time (screen fabrication 3-7 days), and design change inflexibility (new screens required for graphic modifications). Screen printing suits established designs with moderate-to-high production volumes requiring durable vibrant graphics.

Digital Printing: Inkjet-based digital printing deposits UV-curable or solvent inks directly on substrate without screens or tooling. Advantages include zero setup cost or tooling (ideal for prototypes and low volumes), fast turnaround (hours versus days for screen preparation), unlimited color capability (photo-quality full-color graphics), and design flexibility (graphic changes via file update without tooling). Limitations include higher per-unit cost versus screen printing at volume (digital cost-effective <500-1,000 units, screen printing more economical above), potentially limited opacity (may require white underprint for dark substrates), and printer availability (not all membrane switch manufacturers offer digital capability). Digital printing revolutionizes prototyping (enabling rapid iteration) and small-batch production (custom designs, limited editions, low-volume specialty products).

Hybrid Approaches

Combined Methods: Sophisticated overlays may employ multiple printing technologies leveraging respective advantages. Example: screen-printed white underprint (opaque background blocking substrate show-through) plus screen-printed spot colors (brand-specific Pantone colors requiring exact match) plus digital-printed photographic image (complex gradients or photos impractical via screen printing). Hybrid approach optimizes quality and cost—screen printing for elements benefiting from thick opaque inks, digital for complex multi-color content. Cost premium versus single-method approach justified when quality or capability requirements exceed single-technology limitations.

Screen Printing Methods

Screen printing remains dominant membrane switch graphic overlay printing technology—proven performance, vibrant colors, excellent durability, and economical high-volume production.

Screen Printing Process

Screen Preparation: Mesh screen (polyester or stainless steel) coated with photo-sensitive emulsion exposed through film positive creating stencil—UV light hardens emulsion in non-image areas, image areas wash away leaving open mesh. Screen mesh count (threads per inch) affects ink deposit thickness and detail capability—coarser mesh (110-160 tpi) deposits thick ink for opacity and durability, finer mesh (200-305 tpi) enables fine detail and thin deposits. Screen fabrication cost $150-300 per color amortizes over production run.

Printing Process: Substrate (polyester or polycarbonate film) positioned on vacuum table maintaining flatness. Screen lowered into contact with substrate, squeegee forces ink through open mesh areas onto substrate, screen lifts leaving ink deposit. Ink cures via air-dry (solvent evaporation), UV exposure (UV-curable inks), or thermal bake (heat-cure inks). Multi-color graphics require sequential printing—each color printed and cured before next color, registration accuracy ±0.1-0.3mm typical maintaining color alignment. Production rates 200-600 prints per hour depending on ink cure method, color count, and handling automation.

Ink Systems for Screen Printing

UV-Curable Inks: UV inks cure via ultraviolet light exposure creating cross-linked polymer film. Advantages include instant cure (seconds of UV exposure versus minutes air-dry), excellent adhesion to polyester and polycarbonate, superior durability and chemical resistance, low VOC emissions (environmentally friendly), and fast production (no dry time enables immediate handling). UV inks dominate modern membrane switch production—vibrant colors, proven reliability, production efficiency. Cost moderate—$40-80 per kilogram (covering 300-600 square feet depending on deposit thickness and coverage).

Solvent-Based Inks: Traditional inks cure through solvent evaporation and oxidation. Lower material cost ($25-50 per kilogram) but slower production (dry time 10-30 minutes), VOC emissions (environmental and regulatory concerns), and potential solvent retention (residual odor or outgassing). Solvent inks declining in favor of UV systems despite cost advantage—production efficiency and environmental benefits justify UV premium. Solvent inks remain in some applications requiring specific properties (extreme flexibility, very thick deposits) or when equipment investment in UV curing not justified for low-volume specialized production.

Screen Printing Quality Factors

Opacity and Coverage: Ink opacity critical for vibrant appearance—adequate coverage blocks substrate color show-through creating uniform graphic appearance. First-surface printed graphics (ink on viewer side) require single pass opacity, second-surface printing (ink on rear, viewed through clear overlay) demands complete coverage preventing backlight or substrate visibility. Opaque white underprint provides base for transparent or translucent colors ensuring consistent appearance regardless of substrate or lighting. Screen printing excels at opacity—thick ink deposits (8-25 micron typical) create excellent coverage in single pass (first-surface) or double-pass (second-surface requiring maximum opacity).

Detail and Resolution: Screen printing achieves 0.15-0.30mm minimum line width and gap depending on mesh count and ink properties. Fine detail (small text, intricate logos) requires high mesh count (230-305 tpi), precise screen tension, and appropriate ink viscosity. Typical membrane switch graphics (buttons 8mm+ diameter, text 8-point+, logo detail >0.25mm) readily achievable with standard screen printing. Extremely fine detail (<0.15mm features, photo-quality images) may exceed practical screen printing capability suggesting digital printing alternative.

Digital Printing Technologies

Digital printing enables low-volume production, rapid prototyping, and full-color graphics without tooling investment—transforming membrane switch development and specialty production.

UV-Curable Digital Printing

Technology and Capabilities: UV-curable inkjet printers deposit UV-curing inks directly on substrate, inline UV exposure instantly cures printed image. Industrial flatbed or roll-to-roll UV printers handle polyester and polycarbonate films—resolution typically 600-1440 dpi enabling photo-quality output. Advantages include full-color capability (CMYK plus white creates unlimited color combinations), no setup cost (design files directly drive printer), fast turnaround (hours for digital versus days for screen preparation), and design flexibility (customization, versioning, variable data printing). Digital printing cost structure favors low volumes—economical for 1-500 units, screen printing more cost-effective above 1,000+ units. Digital prototyping accelerates development—iterating overlay designs without screen costs enabling rapid refinement before production tooling commitment.

Solvent and Eco-Solvent Digital Printing

Outdoor and Specialty Applications: Solvent-based digital printers use solvent or eco-solvent inks offering superior outdoor durability and substrate compatibility. Advantages include excellent UV resistance (outdoor graphics maintain appearance years longer than some UV-curable inks), substrate versatility (adheres to wide material range including untreated films), and vibrant saturated colors. Limitations include slower production (solvent evaporation requires dry time), VOC emissions (ventilation requirements), and potential odor. Eco-solvent inks reduce environmental impact while maintaining outdoor durability. Solvent digital suits outdoor equipment overlays, specialty materials, or applications prioritizing extreme UV resistance over production speed.

Digital Printing Limitations and Solutions

Opacity Challenges: Digital inks deposit thin layers (2-8 micron) versus screen printing (8-25 micron)—reduced opacity requiring multiple passes or white underprint for dark substrates. Solutions include white underprint (digital white ink layer behind colors providing opaque base), multiple color passes (2-3 passes building opacity at expense of production speed), or hybrid approach (screen-printed white underprint plus digital colors optimizing opacity and color flexibility). Opacity critical for backlit applications—thin digital inks may allow excessive light transmission requiring opaque blocking layers.

Durability Optimization: Digital inks may exhibit less abrasion resistance than thick screen-printed deposits. Enhancement strategies include protective overlaminate (clear polyester film over printed graphics adding scratch resistance and durability), UV-curable coating (liquid coating flood-coated over digital print creating protective layer), or hard-coat treatments (abrasion-resistant coatings improving wear resistance). Protective layers add cost ($0.30-0.80 per switch) but extend digital-printed overlay life matching screen-printed durability for demanding applications.

Surface Finishes and Textures

Surface finish selection affects appearance, functionality, and user experience—matching finish to application requirements optimizes usability and aesthetic appeal.

Gloss and Matte Finishes

Glossy Finishes: High-gloss overlay surfaces provide brilliant color saturation, premium appearance, and easy cleaning. Gloss enhances color vibrancy—smooth surface reflects light uniformly maximizing perceived color intensity and creating showroom-quality aesthetic. However, gloss disadvantages include glare under bright lighting (reflections obscure graphics reducing readability), fingerprint visibility (skin oils show prominently on glossy surfaces creating smudged appearance), and scratch visibility (surface damage more apparent on high-gloss finish). Glossy overlays suit indoor controlled-lighting applications emphasizing appearance—retail displays, consumer electronics in moderate use, applications where visual appeal outweighs glare concerns.

Matte Finishes: Matte (satin, velvet) finishes diffuse light reducing reflections and glare. Matte advantages include excellent readability in bright environments (minimal glare under overhead lights or sunlight), reduced fingerprint visibility (textured surface masks skin oils), and sophisticated appearance (professional aesthetic versus consumer-oriented gloss). Matte disadvantages include slightly reduced color vibrancy (textured surface scatters light reducing perceived saturation), potential dirt accumulation in texture (versus smooth gloss easily wiped clean), and printing considerations (matte surface may affect ink adhesion or color consistency requiring process optimization). Matte finishes optimal for medical devices (clinical lighting environments), outdoor equipment (sunlight exposure), industrial controls (shop floor overhead lighting), and applications prioritizing function over showroom appeal.

Anti-Glare and Anti-Fingerprint Treatments

Optical Coatings: Specialized surface treatments enhance functionality beyond standard finishes. Anti-glare (AG) coatings use fine surface texture or chemical etching creating light diffusion—reduces reflections 80-95% versus untreated gloss dramatically improving readability in bright environments. Anti-fingerprint (AF) coatings employ oleophobic (oil-repelling) chemistry preventing fingerprint adhesion—smudges wipe away easily versus untreated surfaces accumulating visible oils. Anti-reflective (AR) coatings use optical interference films minimizing surface reflections for maximum clarity—critical for display windows or applications demanding zero glare. Treatment costs $0.30-1.20 per square foot adding to base material cost but delivering functional benefits justifying investment for demanding applications. Medical devices, outdoor equipment, public-access terminals, and high-end consumer electronics commonly specify treated surfaces improving usability and maintaining clean professional appearance.

Textured Surfaces

Embossed and Formed Textures: Physical surface textures created through embossing, forming, or material inherent structure provide tactile differentiation and functional benefits. Fine leather-grain, linen, or geometric patterns create visual interest, reduce glare/fingerprints through light diffusion, and provide tactile feedback communicating premium quality. Coarser textures improve grip (portable equipment, handheld controls) and hide scratches/wear (textured surfaces mask damage better than smooth finishes). Texture implementation includes embossed polyester (roller or plate embossing creating permanent texture), textured polycarbonate (material formulated with surface structure), or applied texture films (adhesive-backed textured overlays). Design consideration: texture affects graphic quality—fine detail may be obscured by coarse texture, smooth areas often incorporated for critical graphics/legends while textured borders provide functional benefits.

Durability and Wear Resistance

Overlay longevity critically affects product appearance and user satisfaction—systematic durability optimization ensures graphics withstand operational life without premature degradation.

Abrasion Resistance Testing

Taber Abraser Validation: ASTM D1044 Taber test quantifies abrasion resistance—CS-10F abrasive wheels under 500g or 1000g load cycle across overlay surface. Testing protocol: measure initial haze or appearance, apply defined abrasion cycles (100, 500, 1,000, 5,000, 10,000 cycles typical test points), measure haze increase or visual appearance change, determine cycles until unacceptable degradation (specified haze threshold or visible wear). Hard-coated polyester withstands 10,000-50,000+ cycles before significant wear, standard polyester 1,000-10,000 cycles, polycarbonate 500-5,000 cycles, digital-printed overlays with protective overlaminate 5,000-25,000 cycles. Testing validates overlay specification—compare abrasion performance against expected product use (button actuation frequency, expected service life) confirming adequate durability margin.

Chemical Resistance Validation

Exposure Testing Protocol: Chemical resistance testing exposes overlay samples to application-specific chemicals simulating field exposure. Test procedure: identify relevant chemicals (cleaning agents, disinfectants, solvents, process fluids product encounters), prepare test samples (as-manufactured overlays), expose to chemicals at expected concentrations (immersion or wipe testing at operating temperature), evaluate appearance and properties (visual inspection, adhesion testing, mechanical properties), determine acceptable exposure limits. Medical device overlays test against isopropanol, bleach, hydrogen peroxide, quaternary ammonium disinfectants—validate material selection withstands required cleaning protocols. Industrial overlays test against oils, greases, coolants, solvents specific to application environment. Testing prevents field failures—identifying incompatible materials before production deployment.

UV and Weather Resistance

Accelerated Weathering: QUV or Xenon arc weathering chambers simulate years of outdoor exposure in accelerated timeframe. Testing exposes overlays to UV radiation, moisture, and temperature cycling—typically 1,000-2,000 hours equivalent to 1-3 years outdoor exposure depending on test intensity and correlation factors. Evaluation measures color fade (Delta E color change), gloss retention, mechanical properties, and graphic integrity. UV-stabilized polyester exhibits minimal degradation (<5 Delta E after 2,000 hours), standard materials may show 10-20 Delta E indicating visible fading. Outdoor equipment overlays should demonstrate <10 Delta E after testing equivalent to expected service life ensuring appearance retention throughout product deployment.

Color Management and Consistency

Achieving accurate consistent color reproduction ensures brand identity compliance and professional appearance across production.

Color Specification Systems

Pantone Matching System (PMS): Pantone provides standardized color communication—numeric codes identify specific colors enabling consistent specification across design, proofing, and production. Screen printing easily matches Pantone colors through custom ink formulation—mixing base inks to achieve specified color within tolerance (typically Delta E <2 acceptable color match). Custom Pantone ink mixing cost minimal ($20-40 setup per color) enabling precise brand color reproduction. Digital printing color matching more challenging—CMYK process colors approximate Pantone spot colors but perfect match impossible for some colors (particularly saturated blues, oranges, purples exceeding CMYK gamut). Hybrid approach screen-prints critical brand colors (logo, accent colors demanding exact match) while digital-printing photographic content accepting CMYK limitations.

Color Consistency Control

Production Monitoring: Color variation between production lots creates unprofessional appearance and brand inconsistency. Control strategies include ink lot control (using single ink production batch for entire product run ensuring consistency), color measurement (spectrophotometer measuring printed samples comparing against standard), statistical process control (plotting color measurements identifying drift requiring correction), and visual inspection (trained operators comparing production to approved color standard). Acceptable color tolerance typically Delta E <3 between units (difference imperceptible to most observers), Delta E >5 visible requiring investigation and correction. First-article inspection establishes color baseline, ongoing monitoring maintains consistency throughout production.

Substrate and Lighting Effects

Metamerism and Viewing Conditions: Color appearance varies with lighting—colors matching under one light source (D65 daylight, incandescent, fluorescent) may appear different under alternative illumination. Metamerism affects color-critical applications—medical devices viewed under various clinical lighting, automotive applications transitioning between daylight and artificial lighting, retail displays under diverse store lighting. Color specification should reference viewing conditions—D65 daylight most common standard, CWF (cool white fluorescent) for indoor commercial environments. Critical applications validate color appearance under multiple illuminants ensuring acceptable appearance across expected viewing scenarios.

Embossing and Tactile Features

Embossing creates physical surface relief providing tactile feedback, visual differentiation, and premium aesthetic beyond flat printed graphics.

Embossing Methods

Male-Female Die Embossing: Matched metal dies (male convex, female concave) form overlay material creating raised or recessed features. Material heated to forming temperature, pressed between dies under pressure, cooled maintaining formed shape. Embossing creates button outlines (raised borders communicating button location through touch), logos (dimensional branding elements), text (tactile legends for accessibility), or decorative patterns. Emboss depth typically 0.1-0.5mm depending on material thickness and design—deeper embossing creates more pronounced tactile but requires thicker materials and may compromise flexibility. Embossing tooling cost $800-2,500 depending on complexity amortizing over production volume (economical >2,000-5,000 units).

Embossing Design Considerations

Material and Thickness Requirements: Embossing requires appropriate material selection—polyester and polycarbonate both formable, minimum 0.125mm thickness for shallow embossing, 0.175-0.25mm preferred for pronounced features. Emboss geometry affects formability—gradual transitions and radiused corners form more reliably than sharp angles, excessive depth (>2× material thickness) may cause thinning or material failure. Graphic integration with embossing requires planning—printing before embossing (graphics may distort in formed areas), printing after embossing (requires specialized printing adapting to dimensional surface), or separate printed layer beneath embossed clear overlay (preserving flat graphics while providing tactile surface).

Benefits and Limitations

Functional and Aesthetic Value: Embossing advantages include tactile feedback (users locate buttons by feel without looking—beneficial for frequently-used controls, accessibility applications), premium appearance (dimensional features convey quality and sophistication), brand differentiation (distinctive physical design elements), and functional button definition (physical barriers preventing accidental activation of adjacent buttons). Limitations include added cost (tooling $800-2,500, forming adds production time), design constraints (embossed features limited by material formability), and potential durability concerns (creases in embossed areas may exhibit accelerated wear). Cost-benefit analysis determines embossing justification—premium products emphasizing appearance and tactile quality justify investment, economy products typically forego embossing minimizing cost.

Cost Optimization Strategies

Balancing overlay performance requirements against cost constraints requires strategic material and printing selection optimizing total value.

Material Cost Analysis

Material Selection Trade-offs: Overlay material costs range from $0.80-4.50+ per square foot depending on type, thickness, and treatments. Standard 0.125mm polyester ($0.80-1.50/sq ft) provides excellent value for typical applications—good durability, chemical resistance, adequate appearance. Hard-coated polyester ($1.50-2.50/sq ft) justifies cost for high-wear applications—abrasion resistance extends appearance retention reducing warranty costs. Polycarbonate ($2.00-4.50/sq ft) premium only justified when impact resistance or flame rating genuinely required—many applications specify polycarbonate unnecessarily when polyester adequate saving 40-60% material cost. Specialty treatments (anti-glare, anti-fingerprint $0.30-1.20/sq ft additional) warrant evaluation—functional benefits versus cost premium. Material waste also affects economics—efficient nesting maximizing usable area from material sheet reduces scrap improving material yield.

Printing Method Economics

Volume-Based Selection: Printing cost structure varies dramatically by technology and volume. Digital printing: $2-8 per switch for prototypes and low volumes (<100 units), $1-4 per switch for moderate volumes (100-500 units), setup cost zero. Screen printing: $150-300 per color setup, $0.30-1.50 per switch at volume (>1,000 units), decreasing to $0.15-0.80 at high volume (>10,000 units). Crossover volume where screen printing becomes economical versus digital typically 500-1,500 units depending on complexity and color count. Volume planning affects printing selection—established products with predictable demand favor screen printing economy at volume, custom/low-volume products optimize with digital avoiding setup costs. Prototyping universally benefits from digital—rapid iteration without screen investment accelerating development.

Design Simplification

Cost-Reducing Design Strategies: Overlay design choices significantly impact cost. Strategies include minimizing color count (fewer screen printing colors reduces setup cost, consider grayscale or limited palette), simplifying graphics (avoiding extremely fine detail enables coarser screens and faster printing), eliminating special finishes (standard finishes versus specialty treatments), avoiding embossing (flat overlays versus dimensional features saving tooling), and optimizing sizes (standard material widths reducing waste). Design simplification potentially saves 30-50% overlay cost versus elaborate multi-color embossed designs—value engineering balances appearance goals against cost constraints identifying optimization opportunities.

Quality Control and Testing

Comprehensive quality control ensures overlay appearance, durability, and functionality meet specifications supporting consistent production quality.

Visual Inspection Criteria

Appearance Standards: Visual inspection identifies defects and appearance issues. Inspection criteria include color accuracy (comparing to approved standard, Delta E <3 acceptable), print quality (crisp edges, no ink bleeding or gaps, uniform coverage), surface defects (scratches, contamination, bubbles, pinholes), registration accuracy (multi-color alignment within ±0.2mm), and dimensional accuracy (overall size, die-cut accuracy ±0.2mm). Inspection protocols define defect classification—critical defects (affecting function or customer-visible appearance) require 100% inspection and rejection, major defects (appearance issues in less-critical areas) evaluated against acceptable quality level (AQL), minor defects (cosmetic issues not affecting performance or visibility) tracked but may not justify rejection depending on criticality and cost. Inspection lighting standardized (D65 viewing booth) ensuring consistent evaluation conditions.

Adhesion and Lamination Testing

Peel Strength Validation: Overlay adhesive bonding to circuit layers validated through peel testing. ASTM D3330 180° peel test measures force required separating adhesive bond—test specimen bonded to standard substrate, pulled at 180° angle at specified rate (12 inches/minute typical), force recorded throughout peel. Acceptable peel strength typically >500 g/inch for permanent bonds ensuring overlay withstands handling and environmental exposure without delamination. Low peel strength indicates adhesion issues requiring surface treatment, adhesive selection change, or bonding process optimization. Testing both initial adhesion and aged adhesion (after environmental exposure, temperature cycling) confirms long-term bond reliability.

Functional Testing

Assembly Validation: Complete membrane switch assembly functional testing verifies overlay integration preserves tactile performance, electrical function, and environmental sealing. Testing includes tactile force measurement (confirming overlay doesn't excessively increase actuation force or degrade snap ratio), electrical continuity (verifying switch circuit function through overlay layers), seal integrity (IP testing confirming overlay adhesive bonding maintains environmental protection), and appearance evaluation (final assembly appearance meeting aesthetic specifications). First-article inspection validates new designs before production release, ongoing sampling monitors production consistency.

Frequently Asked Questions

Should I choose polyester or polycarbonate for my membrane switch overlay?

Polyester (PET) represents optimal choice for 80-90% of membrane switch applications offering excellent balance of performance, durability, and cost. Choose polyester when application requires chemical resistance (medical devices cleaned with alcohol disinfectants, industrial equipment exposed to solvents/chemicals), abrasion resistance (high-wear applications benefit from hard-coated polyester), outdoor durability (UV-stabilized polyester withstands years of sunlight), or cost optimization (polyester 40-60% less expensive than polycarbonate $0.80-2.50/sq ft versus $2.00-4.50/sq ft). Polyester suits medical devices, industrial controls, outdoor equipment, consumer electronics, and general commercial applications where balanced performance valued. Choose polycarbonate (PC) only when application genuinely requires impact resistance (portable equipment subject to drops, harsh industrial or public-access environments requiring vandal resistance, applications where breakage risk justifies premium), flame retardant certification (UL94 V-0/V-2 ratings for medical devices, aviation, electrical equipment mandating flammability standards), or premium aesthetic (high-gloss appearance for luxury consumer electronics, automotive applications). However, recognize polycarbonate limitations—poorer chemical resistance (attacked by alcohols, many solvents, ammonia cleaners making unsuitable for frequently-disinfected medical devices), scratching susceptibility (softer surface versus hard-coated polyester), UV yellowing (standard grades yellow outdoors requiring UV-stabilized formulations), and higher cost. Decision framework: default to polyester unless specific requirement mandates polycarbonate capabilities. Many applications unnecessarily specify polycarbonate when polyester delivers adequate performance at substantially lower cost. Medical devices requiring alcohol disinfection strongly favor polyester due to polycarbonate chemical incompatibility despite polycarbonate impact advantages. Industrial equipment frequently cleaned with solvents better served by polyester chemical resistance. Outdoor applications demand UV-stabilized polyester superior outdoor durability. Polycarbonate justified primarily for genuine impact-critical applications (portable devices, harsh environments) or flame rating requirements—where these specific capabilities outweigh cost premium and chemical/UV limitations.

What printing method should I use for membrane switch overlays?

Printing method selection depends primarily on production volume, color requirements, and development stage. Screen printing optimal for established designs with moderate-to-high production volumes (>1,000 units) requiring vibrant durable graphics—advantages include exceptional opacity (thick ink deposits create solid coverage), color vibrancy (custom Pantone inks match brand colors precisely), proven durability (thick ink layers withstand abrasion), and economical high-volume production ($0.15-0.80 per switch at >5,000+ units). Setup costs $150-300 per color amortize over production making screen printing cost-effective above 1,000-1,500 unit volumes. Screen printing suits established products with predictable demand, applications requiring exact Pantone color matching, designs emphasizing durability over photo-quality detail. Digital printing (UV-curable inkjet) optimal for prototypes, low-volume production (<500 units), and designs requiring full-color photo-quality graphics—advantages include zero setup cost (no tooling or screens required), fast turnaround (hours versus days for screen preparation), unlimited color capability (CMYK plus white creates photo-quality images), and design flexibility (graphic changes via file update without tooling cost). Digital cost-effective for 1-500 units ($1-8 per switch), screen printing more economical above 1,000+ units. Digital revolutionizes prototyping—enabling rapid design iteration, customer approval samples, market testing without screen investment. Low-volume specialty products (custom designs, limited editions, personalized versions) benefit from digital economics. Hybrid approaches combine advantages—screen-printed Pantone spot colors (brand-critical exact color match) plus digital-printed photographic elements (complex images impractical via screen). Production planning influences selection: prototype phase universally uses digital for flexibility, established production transitions to screen printing for volume economics, consider maintaining digital capability for design variations or custom versions. Color requirements matter—simple designs with 1-3 solid colors favor screen printing simplicity and opacity, complex multi-color photographic content better suited to digital full-color capability. Quality considerations: screen printing delivers superior opacity and abrasion resistance via thick ink deposits, digital prints may require protective overlaminate for demanding wear applications adding $0.30-0.80 cost but matching screen durability.

How do I improve membrane switch overlay abrasion resistance?

Overlay abrasion resistance optimization employs multiple strategies depending on application wear severity and cost constraints. Hard-coated polyester films provide superior abrasion resistance versus standard polyester—silica or silicone-based surface coating increases wear resistance 2-5× (withstanding 10,000-50,000+ Taber cycles versus 1,000-10,000 for uncoated). Hard-coat cost premium 30-50% ($1.50-2.50/sq ft versus $0.80-1.50 standard polyester) justified for high-wear applications—public access terminals, industrial equipment with frequent button actuation, portable devices subject to abrasive contact. Implement hard-coat when accelerated testing reveals standard materials insufficient for expected service life. Protective overlaminates add clear protective film over printed graphics—0.050-0.125mm polyester or polycarbonate film with hard coating laminated over printed overlay. Overlaminate advantages include protecting printed graphics from direct abrasion (wear occurs on replaceable protective layer versus permanent graphics), enabling protective coatings on digitally-printed overlays (matching screen-printed durability), and adding chemical/UV resistance. Overlaminate cost $0.30-0.80 per switch depending on material and size. Screen printing with UV-curable inks delivers inherent abrasion resistance—thick ink deposits (10-25 micron) withstand wear better than thin digital prints (2-8 micron). UV inks cross-link creating durable polymer film resistant to scratching, chemicals, and UV exposure. Applications prioritizing maximum durability favor screen printing despite higher setup costs. Embossed button areas concentrate wear on raised surfaces rather than flat graphics—embossed borders protect critical legends in button centers. Textured finishes mask wear better than smooth surfaces—fine texture hides scratches appearing obvious on glossy smooth overlays. Surface treatments including anti-fingerprint coatings reduce perceived wear (cleaner appearance despite actual abrasion). Design strategies minimize wear including oversizing critical graphics (wear-prone legends made larger providing margin before illegibility), high-contrast colors (dark text on light background remains readable despite fading versus low-contrast combinations), and wear-resistant ink colors (blacks and dark colors maintain appearance better than light colors showing dirt/wear prominently). Validation testing confirms optimization effectiveness—Taber abrasion testing comparing material options, measuring cycles until unacceptable degradation, selecting approach meeting expected service life with appropriate safety margin. Systematic optimization balances abrasion resistance against cost—high-wear applications justify hard-coated materials and protective measures, moderate-wear environments adequately served by standard materials minimizing cost.

What surface finish should I specify for my membrane switch overlay?

Surface finish selection depends on operating environment, lighting conditions, user interaction patterns, and aesthetic priorities. Glossy finishes provide vibrant color saturation, premium showroom appearance, and easy cleaning—smooth surface reflects light uniformly maximizing perceived color intensity creating attractive aesthetic. Choose gloss for indoor controlled-lighting applications (retail displays, consumer electronics in moderate use), products emphasizing visual appeal over function, or applications where glare and fingerprints not concerns. Gloss disadvantages include severe glare under bright lighting obscuring graphics, prominent fingerprint visibility creating smudged appearance, and scratch visibility making damage apparent. Matte (satin, velvet) finishes diffuse light reducing reflections and glare—excellent readability in bright environments, reduced fingerprint visibility, and sophisticated professional appearance. Choose matte for medical devices (clinical overhead lighting, frequent handling), outdoor equipment (direct sunlight exposure), industrial controls (bright shop floor lighting), applications prioritizing function and readability over showroom aesthetics. Matte trade-offs include slightly reduced color vibrancy versus gloss and potential texture dirt accumulation. Anti-glare (AG) treatments provide maximum reflection reduction—specialized coatings or surface textures reducing reflections 80-95% dramatically improving readability in extremely bright environments. Specify AG for outdoor equipment in direct sunlight, medical devices under bright surgical lights, automotive dashboards (windshield reflections, bright daylight), or applications where readability under all lighting conditions critical. AG cost premium $0.30-0.80/sq ft justified when glare prevention essential. Anti-fingerprint (AF) coatings employ oleophobic chemistry preventing fingerprint adhesion—smudges wipe away easily versus untreated surfaces. Specify AF for high-touch interfaces (frequent button pressing), consumer electronics emphasizing clean appearance, public-access terminals maintaining professional appearance despite heavy use. AF cost $0.30-0.60/sq ft. Combined AG+AF treatments optimize for bright-environment high-touch applications requiring both readability and clean appearance. Textured surfaces (leather-grain, linen patterns) provide visual interest, reduce glare/fingerprints through diffusion, and hide wear/scratches—choose for portable equipment (grip improvement), premium products (tactile quality perception), or applications where texture hides operational wear. Application-specific recommendations: medical devices favor matte or AG for clinical lighting readability plus AF for frequent handling, outdoor equipment specifies AG plus UV-stable materials for sunlight exposure, consumer electronics balance gloss appearance (showroom appeal) against matte function (home use readability), industrial controls prioritize matte/AG for harsh lighting without appearance concerns. Testing validates selection—evaluate mockups under actual operating conditions (lighting, viewing angles, touch patterns) confirming finish meets functional and aesthetic requirements.

How do I ensure consistent color across membrane switch production?

Color consistency requires systematic controls throughout design, specification, and production. Precise color specification using Pantone Matching System (PMS) provides universal color communication—numeric Pantone codes identify exact colors enabling consistent specification across design, proofing, and production. Specify critical brand colors as Pantone spot colors rather than CMYK process colors—screen printing custom-mixes inks to match Pantone ensuring consistency. Pantone specification eliminates ambiguity of "blue" or "red" providing objective standard. Color standards and approval samples establish baseline—first production run creates approved color standard, subsequent production compares against standard confirming match. Physical approved sample serves as definitive reference preventing interpretation variations. Maintain consistent ink lots—purchase sufficient ink from single production batch for entire product run avoiding batch-to-batch variation. Ink manufacturers blend batches to specifications but minor variations occur between production lots—single lot ensures consistency. Spectrophotometer measurement provides objective color assessment—measure printed samples, compare against standard using Delta E metric (color difference quantification), target Delta E <3 (imperceptible difference to most observers), investigate Delta E >5 (visible requiring correction). Spectrophotometer eliminates subjective visual judgment variations. Statistical process control monitors production—sample frequency (every 50-100 units or hourly), plot color measurements on control charts, detect trends indicating process drift (ink aging, contamination, press variations), implement corrections before out-of-tolerance production. Proactive monitoring prevents color deviation accumulation. Substrate consistency affects color appearance—specify polyester or polycarbonate from qualified suppliers ensuring batch-to-batch consistency, avoid mixing substrate lots mid-production (color appearance varies slightly on different substrate batches). Lighting standardization for visual inspection—D65 viewing booth provides consistent evaluation conditions eliminating ambient lighting variations, define viewing conditions for color-critical approval (daylight D65, cool white fluorescent CWF, or application-specific lighting). Metamerism awareness for applications viewed under multiple illuminants—colors matching under daylight may appear different under fluorescent or incandescent lighting. Critical applications validate color under expected viewing conditions. Digital printing color consistency requires ICC color profiles—printer characterization ensuring consistent CMYK output, regular calibration maintaining accuracy, test prints before production confirming color accuracy. Screen printing consistency requires press maintenance—consistent squeegee pressure, screen tension, ink viscosity monitoring ensuring uniform printing. First-article inspection validates production setup—compare initial production to approved standard before full run commitment. Operator training emphasizes color criticality and inspection standards—trained personnel recognize variations requiring attention. Documentation maintains consistency across time—specifications, approved standards, process parameters recorded enabling consistent production across months or years as repeat orders manufactured. Following systematic color management—precise specification, objective measurement, process control, substrate consistency, standardized evaluation—ensures professional consistent color supporting brand identity and customer satisfaction.

What overlay thickness should I specify for my membrane switch?

Overlay thickness selection balances tactile performance, durability, appearance, and cost requirements. Standard polyester thicknesses include 0.125mm (5 mil, most common), 0.175mm (7 mil), and 0.25mm (10 mil). Polycarbonate typically 0.25mm (10 mil), 0.375mm (15 mil), or 0.50mm (20 mil). Select 0.125mm polyester for standard applications requiring balance of tactile response, durability, and economy—thin material provides good tactile clarity (crisp dome feel transmitted through overlay), adequate durability (suitable for typical actuations 1-5 million cycles), reasonable flexibility, and economical cost ($0.80-1.50/sq ft). 0.125mm suits consumer electronics, general industrial controls, indoor commercial applications without extreme durability demands. Choose 0.175-0.25mm polyester for enhanced durability requirements—thicker material provides better abrasion resistance (more material to wear through), improved chemical resistance (additional thickness resists penetration), reduced puncture susceptibility, and stiffer feel (less overlay deflection during actuation). Thicker polyester suits high-wear applications (public access terminals, industrial equipment with frequent heavy actuation), outdoor equipment (weather durability), or applications prioritizing maximum overlay life. Trade-offs include increased cost (20-40% premium for thicker material), potentially reduced tactile clarity (thick stiff overlay may dampen dome snap feel requiring dome force adjustment), and reduced flexibility (affecting 3D forming if complex shapes required). Polycarbonate 0.25-0.50mm specified when impact resistance required—thicker polycarbonate withstands drops and abuse without cracking. Applications include portable equipment, harsh industrial environments, vandal-resistant public-access devices. Polycarbonate thickness selection balances impact protection (thicker better) against cost and tactile considerations. Tactile optimization consideration: overlay stiffness increases with thickness affecting transmitted tactile feel—thicker overlays may require higher-force domes maintaining acceptable snap ratio, or accept reduced tactile crispness as trade-off for durability benefits. Testing with actual assembly (overlay + spacers + domes) validates tactile performance meeting user expectations. Embossing requirements influence thickness—shallow embossing possible on 0.125mm, pronounced dimensional features require 0.175-0.25mm providing adequate material for forming without thinning or distortion. Cost optimization: specify minimum thickness meeting performance requirements—unnecessary thickness wastes cost without proportional benefit. Application assessment determines requirements—typical indoor moderate-use applications adequately served by 0.125mm, demanding environments justify thicker materials, extreme-duty applications may warrant 0.25mm+ or polycarbonate. Prototype testing validates thickness selection—evaluate tactile feel, appearance, durability under realistic use confirming specified thickness meets requirements or identifying adjustment needs before production commitment.

Conclusion

Graphic overlay material and printing method selection critically determines membrane switch appearance, durability, functionality, and cost—superior overlay design delivers attractive professional graphics, withstands environmental exposure and operational wear throughout product life, provides appropriate tactile and surface characteristics supporting user experience, and optimizes manufacturing cost matching performance requirements to application demands. The comprehensive overlay knowledge outlined in this guide—material options and properties, selection criteria considering chemical resistance, abrasion resistance, environmental stability, printing technology comparison, screen and digital printing capabilities, surface finish options, durability optimization, color management, embossing techniques, cost-performance trade-offs, and quality control methods—provides technical foundation for confident overlay decisions supporting product success.

Polyester (PET) represents optimal overlay material for 80-90% of membrane switch applications—excellent chemical resistance (alcohols, mild acids/bases, solvents suitable for medical disinfection and industrial exposure), good abrasion resistance (hard-coated grades achieving 10,000-50,000+ Taber cycles), superior outdoor durability (UV-stabilized formulations withstanding years of sunlight), and economical cost ($0.80-2.50/sq ft versus $2.00-4.50 polycarbonate). Standard 0.125mm polyester balances tactile clarity, adequate durability, and cost for typical applications. Polycarbonate justified only when genuine impact resistance required (portable equipment, harsh environments) or flame rating mandated—cost premium and chemical/UV limitations restrict to applications where specific capabilities outweigh polyester advantages.

Printing method selection depends primarily on production volume—screen printing optimal for established products >1,000 units offering vibrant opaque colors, excellent durability, Pantone color matching, and economical high-volume production ($0.15-0.80 per switch at volume). Digital printing revolutionizes prototyping and low-volume production (<500 units) through zero setup cost, fast turnaround, full-color capability, and design flexibility enabling rapid iteration and specialty production. Hybrid approaches combining screen-printed spot colors with digital-printed imagery optimize quality and capabilities.

Surface finish selection affects usability and appearance—matte/anti-glare finishes provide superior readability in bright environments suited to medical devices, outdoor equipment, industrial controls prioritizing function. Glossy finishes deliver vibrant appearance for indoor controlled-lighting consumer products emphasizing aesthetics. Anti-fingerprint treatments maintain clean appearance for high-touch interfaces. Systematic finish selection matching operational environment and user interaction patterns optimizes functionality.

Durability optimization through hard-coated materials, protective overlaminates, UV-curable inks, and validation testing ensures overlay appearance retention throughout product service life preventing premature degradation and warranty claims. Color consistency via Pantone specification, spectrophotometer measurement, process control, and standardized evaluation maintains brand identity and professional quality across production.

At JASPER, our 15 years of membrane switch manufacturing experience demonstrates that effective graphic overlay design requires balanced consideration of material properties, environmental exposure, wear patterns, printing capabilities, aesthetic requirements, and cost constraints. We partner with customers selecting appropriate materials, optimizing printing methods, specifying surface finishes, validating durability through comprehensive testing, ensuring color consistency, and supporting production delivering excellent overlay quality. Our engineering team maintains extensive material and ink resources, conducts durability and color testing in certified laboratory, provides transparent cost-performance guidance, and helps optimize overlay specifications balancing appearance and durability against budget achieving professional results supporting product success. Contact us to discuss your membrane switch graphic overlay requirements and develop solutions delivering superior visual appeal, robust durability, and optimal value.

References and Further Reading

- ASTM D1044, "Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion," ASTM International, 2018

- ASTM D3330, "Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape," ASTM International, 2018

- ASTM G154, "Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials," ASTM International, 2016

- ISO 4892-2, "Plastics - Methods of Exposure to Laboratory Light Sources - Part 2: Xenon-Arc Lamps," International Organization for Standardization, 2013

- Pantone LLC, "Pantone Color Bridge Guide," 2023 Edition

- Harper, C.A., "Handbook of Plastics, Elastomers, and Composites," McGraw-Hill, 2022

- Kipphan, H., "Handbook of Print Media," Springer, 2001

- Seymour, R.B. and Carraher, C.E., "Polymer Chemistry," CRC Press, 2019

Relevant news