Custom vs. Standard Membrane Switch Designs: Engineering Decision Guide

Time:

2025-12-18

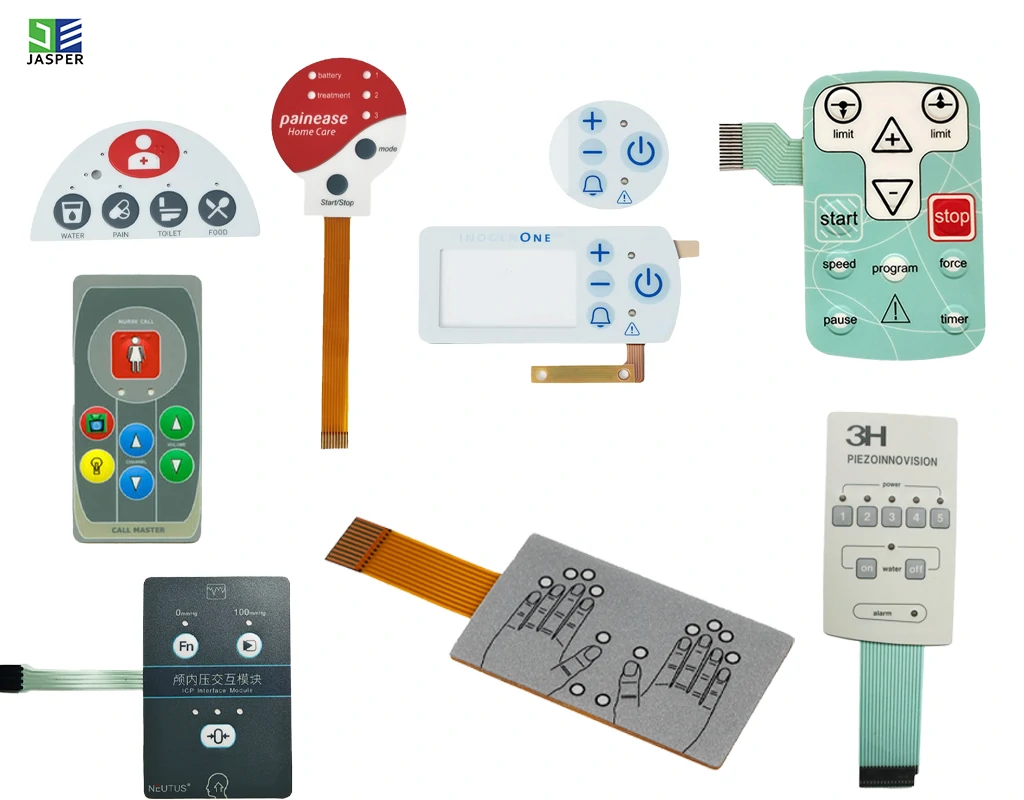

Expert guide to choosing between custom and standard membrane switch designs covering cost analysis, break-even points, development timelines, customization options, and decision criteria.

Table of Contents

- Introduction

- Standard Membrane Switch Designs

- Custom Membrane Switch Designs

- Decision Criteria: Custom vs. Standard

- Cost Analysis and Break-Even Points

- Customization Options and Capabilities

- Design and Development Process

- Timeline and Lead Time Considerations

- Production Volume Impact on Economics

- Engineering and Technical Considerations

- Risk Assessment and Mitigation

- Case Studies and Real-World Examples

- Frequently Asked Questions

- Conclusion

Quick Answer: Custom membrane switch designs justify investment at production volumes exceeding 1,000-3,000 annual units (depending on complexity) where tooling costs ($800-5,000 typical) amortize below $2-5 per-unit premium, while standard off-the-shelf designs suit low-volume applications (<500-1,000 units annually), rapid deployment timelines (<4-6 weeks), or applications where standard configurations adequately meet functional requirements without design-specific optimization.

The custom versus standard membrane switch decision fundamentally impacts product differentiation, user experience quality, time-to-market, development costs, and long-term manufacturing economics. Standard switches offer immediate availability, proven reliability, and minimal engineering investment—but constrain design freedom to existing configurations potentially compromising optimal user interface implementation. Custom designs enable precise tailoring to specific product requirements, brand identity expression, and user experience optimization—but require tooling investment, extended development timelines, and engineering resources justifiable only when production volumes or competitive differentiation demands warrant the incremental cost and effort.

As a membrane switch manufacturer with over 15 years of experience at JASPER, I've guided hundreds of customers through custom-versus-standard decision analysis. A medical device startup initially specified expensive fully-custom switches for a low-volume specialty product (projected 300 annual units)—development cost analysis revealed $18,000 tooling investment creating $60 per-unit cost burden making product economically unviable. Redesigning around modified-standard switches (slight customization to stock configuration) reduced tooling to $2,400 and per-unit premium to $8 enabling profitable production. Conversely, a consumer appliance manufacturer launching high-volume product (50,000+ annual units) attempted cost savings using standard switches—resulting interface proved confusing to users, generated support calls, and damaged brand perception. Investing $4,500 in custom design tooling cost only $0.09 per unit at production volume while delivering intuitive, brand-aligned interface substantially improving user satisfaction and reducing support costs.

This comprehensive guide examines custom versus standard membrane switch decision methodology, economic analysis, design process implications, and strategic considerations ensuring optimal choice for specific application requirements. We'll explore standard design capabilities and limitations, custom design options and development processes, decision criteria balancing cost against benefits, break-even analysis quantifying volume thresholds, timeline implications, engineering considerations, risk assessment, and real-world case studies demonstrating successful decision-making across diverse applications. Whether you're developing medical devices, industrial equipment, consumer appliances, or specialized controls, this analysis provides framework for confident custom-versus-standard decisions optimizing product success, development efficiency, and manufacturing economics.

Standard Membrane Switch Designs

Standard or off-the-shelf membrane switches represent pre-engineered configurations available from manufacturer stock or with minimal modification. Understanding standard design capabilities, typical configurations, and limitations enables assessment of adequacy for specific applications.

Standard Design Characteristics

Pre-Defined Configurations: Standard membrane switches utilize established layouts, materials, and construction methods refined through multiple production cycles. Common standard configurations include numeric keypads (3×4 matrix for phone-style entry, 4×4 for calculator-style), function button arrays (4-12 buttons in linear or grid arrangements), simple control panels (on/off, mode selection, basic adjustment controls), and standard connector options (12-24 position FFC, standard pin headers). These configurations suit common control requirements across diverse applications—equipment interfaces, point-of-sale terminals, access control panels, basic industrial controls, and consumer appliances with straightforward functionality.

Material and Construction Standards: Standard designs employ cost-optimized material selections and proven construction methods. Typical specifications include polyester overlays (0.005"-0.010" thickness, standard graphic capabilities, moderate durability), silver-silver chloride circuits (economical, adequate conductivity for most applications), standard metal domes (catalog force ratings: 180g, 250g, 350g, 500g), pressure-sensitive acrylic adhesives (general-purpose bonding and sealing), and embossing options (standard pillow heights 0.8-1.5mm, basic shapes). Construction follows established processes optimizing manufacturing efficiency—screen printing graphics, standardized lamination sequences, automated dome placement where applicable, and quality control procedures validated through thousands of units production experience.

Availability and Lead Times: Primary advantage of standard designs lies in immediate or near-immediate availability. Truly standard configurations maintained in manufacturer inventory ship within days (3-7 business days typical for stock items). Semi-standard designs requiring minor customization (custom graphics applied to standard construction) deliver in 2-4 weeks—significantly faster than fully custom development requiring 6-12 weeks or more. Rapid availability suits applications with urgent timelines, small pilot productions testing market reception before committing to custom development, or replacement/service parts for legacy equipment where original custom tooling no longer exists.

Standard Design Advantages

Minimal Development Investment: Standard switches eliminate or substantially reduce engineering development costs. No custom tooling required for truly standard configurations—graphics screen printing uses existing screens or simple digital printing, construction employs standard materials and processes, assembly follows established procedures. Development cost for standard switches typically ranges $0-800 (digital custom graphics on standard layout) versus $3,000-8,000+ for fully custom designs. Low development cost particularly benefits startups, small-volume producers, or products in early development stages where minimizing upfront investment preserves cash flow and reduces financial risk.

Proven Reliability: Standard configurations benefit from extensive field history and production validation. Manufacturers have produced hundreds or thousands of essentially identical units, identifying and resolving design weaknesses, optimizing materials and processes, and validating long-term reliability through actual deployed products. This proven track record reduces risk versus untested custom designs potentially harboring undiscovered failure modes. Standard switches ship with confidence they will perform reliably based on substantial field experience rather than relying solely on prototype testing and theoretical analysis.

Simplified Procurement: Standard part numbers simplify ordering, inventory management, and future reordering. Clear part number identification enables straightforward procurement—no need for complex drawings review, specification verification, or sample approval typical with custom designs. Standard switches facilitate multi-source strategies—different manufacturers may offer similar standard configurations enabling competitive sourcing or backup supply. Inventory management simplified through defined part numbers and specifications rather than custom drawing control and revision management.

Standard Design Limitations

Constrained Design Freedom: Standard configurations limit adaptation to specific product requirements. Button layout, size, and spacing follow standard patterns potentially conflicting with optimal ergonomics for specific application. Graphics constrained to standard overlay area and shape—cannot customize outline shape, unusual cutouts, or non-rectangular geometries. Material selections limited to standard offerings—cannot specify specialized materials (exotic overlays, custom adhesives, unique circuit configurations) without moving to custom development. Applications with specific user interface requirements, unique industrial design language, or specialized performance needs may find standard configurations inadequate.

Limited Differentiation: Standard switches offer minimal competitive differentiation—other manufacturers may use identical or similar standard configurations making products appear generic or interchangeable. Brand identity expression limited—standard graphics capabilities support basic logos and text but lack sophisticated visual design, premium materials, or distinctive tactile characteristics differentiating products in competitive markets. Applications where user interface significantly influences purchase decisions or brand perception may require custom design enabling differentiation supporting premium positioning or unique value propositions.

Compromise Performance: Standard designs optimize for broad applicability and cost efficiency rather than excellence in specific applications. Tactile characteristics suit general use but may not provide optimal force, travel, or feedback for specific usage patterns. Environmental protection adequate for typical indoor/moderate conditions but potentially insufficient for harsh environments. Circuit flexibility and connector options accommodate common requirements but may constrain integration for complex electronic architectures. Applications demanding optimized performance, specialized environmental resistance, or integration with unique electronic systems may require custom engineering achieving performance levels beyond standard configuration capabilities.

Custom Membrane Switch Designs

Custom membrane switches represent application-specific designs engineered precisely to product requirements. Custom development enables optimal user experience, brand differentiation, and performance optimization—at cost of tooling investment, extended timelines, and engineering effort.

Custom Design Capabilities

Complete Layout Freedom: Custom designs enable arbitrary button placement, size, and arrangement optimized for specific user tasks and ergonomics. Button positioning matches hand size, finger reach, and typical usage patterns for target user population. Button sizes optimized—critical frequently-used controls larger (easier targeting), secondary functions smaller (efficient space utilization). Layout accommodates product industrial design—switches conform to curved surfaces, unusual outline shapes, integrated with displays or other interface elements creating cohesive visual design. Connector placement, routing, and configuration tailored to specific product electronics architecture and enclosure constraints.

Advanced Materials and Construction: Custom development accesses full material and construction method spectrum. Premium overlay materials—thick polycarbonate (0.030"-0.040") for maximum durability, specialized films with chemical resistance or optical properties, textured or soft-touch surfaces creating distinctive tactile character. Advanced circuit technologies—carbon ink for cost optimization, silver flex for demanding electrical performance, rigid-flex combinations integrating membrane switch with PCB mounting. Specialized tactile feedback—custom metal dome forces and geometries, Piezo haptic feedback, or unique tactile mechanisms. Environmental protection—IP67-IP68 sealing designs, extreme temperature materials, chemical-resistant constructions for harsh environments. Material selection precisely matches application requirements rather than conforming to standard material sets.

Sophisticated Graphics and Branding: Custom graphics enable full brand expression and sophisticated visual design. Unlimited color options (versus limited standard palettes), complex graphics and imagery, photographic quality printing, selective textures creating visual and tactile interest. Premium graphic treatments—metallic inks, transparent windows over displays, backlighting with selective light blocking creating dramatic lit/unlit appearance changes, embedded lenses or optical features. Graphics integration with product industrial design language—colors, typography, iconography aligned with brand standards creating cohesive product identity. Custom shapes and profiles—die-cut outlines matching product contours, 3D embossed features, integrated bezels or trim elements.

Custom Design Development Process

Requirements Definition and Specification: Custom development begins with comprehensive requirements documentation. Specifications include dimensional requirements and mechanical constraints (available mounting area, thickness limitations, connector location, attachment method), electrical requirements (circuit resistance, contact ratings, connector type and pinout, electrical isolation), environmental requirements (operating temperature range, IP rating, chemical exposure, UV resistance), tactile requirements (actuation force, travel distance, feedback character), aesthetic requirements (graphics design, colors, surface finish, brand standards), and performance requirements (cycle life, response time, operating conditions). Detailed specifications enable effective design and prevent costly mid-development changes when requirements clarify late in process.

Conceptual Design and Review: Initial design phase creates conceptual layouts and constructions meeting specifications. Designers propose button arrangements, overlay configurations, circuit architectures, and construction approaches balancing requirements against cost and manufacturability. Conceptual designs typically present 2-3 alternative approaches with trade-off analysis—different material selections, layout variations, or construction methods offering distinct advantages. Customer review and feedback refines concepts identifying preferred direction. Iterative review cycles converge on design approach optimizing requirements satisfaction, cost, and manufacturing feasibility before detailed engineering begins.

Detailed Engineering and Prototyping: Selected concept advances to detailed engineering creating complete specifications, drawings, and prototype builds. Engineering develops overlay artwork and die-cut specifications, circuit layout and electrical testing, dome selection and placement, assembly stack-up and adhesive specifications, connector configuration, and complete dimensional drawings with tolerances. Prototypes built to engineering specifications provide physical samples for evaluation. Prototype testing validates functional performance (electrical resistance, tactile characteristics, environmental protection), evaluates user experience (button layout, tactile feel, graphics clarity), verifies mechanical fit and integration, and identifies any design refinements before tooling investment and production commitment.

Customization Levels and Approaches

Minimal Customization (Modified Standard): Lowest-cost custom approach modifies standard configurations with application-specific graphics and minor layout adjustments. Standard base construction (materials, circuit configuration, general layout) combined with custom graphics printed to customer artwork, button arrangement variations within standard overlay size, and connector location or type alternatives from standard catalog. Tooling limited to graphics screens ($300-1,200) and minimal die-cutting dies if outline shape modified. Development timeline compressed (3-5 weeks versus 8-12 weeks fully custom), cost reduced (total development $800-2,500), while enabling significant differentiation through graphics and moderate layout optimization. Minimal customization suits moderate-volume applications (1,000-5,000 annual units) where standard base construction adequate but custom graphics and minor layout changes provide meaningful user experience or branding improvements.

Moderate Customization: Mid-level customization employs some standard elements while customizing others to application requirements. Custom overlay outline shape and die-cutting matching product contours, custom button layout optimized for specific tasks, custom graphics with advanced techniques (selective textures, metallic inks, backlighting), but standard circuit construction and materials, standard dome selections and placement methods, proven assembly processes. Tooling includes custom overlay cutting dies ($800-2,000), graphics screens or digital printing setup ($500-1,500), potentially custom dome placement fixtures ($400-1,200) if layout substantially differs from standard patterns. Development cost typically $2,500-5,000, timeline 6-8 weeks. Moderate customization balances optimization against investment—suitable for volumes 3,000-15,000 annual units where layout and graphics customization substantially improve user experience justifying tooling investment.

Full Customization: Comprehensive custom engineering creates application-optimized design from first principles. Every aspect specified for application—custom overlay materials and constructions (multi-layer films, specialized substrates), custom circuit layout and materials (optimized trace routing, material selection for electrical performance or cost), custom dome selection or development (specific force-travel characteristics, custom geometries), advanced assembly techniques (selective sealing, integrated components, complex lamination sequences), specialized testing and validation. Tooling investment substantial—overlay dies ($1,200-3,000), circuit dies and screens ($1,000-2,500), assembly fixtures ($800-2,000), testing fixtures ($500-1,500), total development $4,000-10,000+ depending on complexity. Timeline extended (8-12+ weeks for development and validation). Full customization justifies at high volumes (>15,000-20,000 annual units) or applications where optimized performance, competitive differentiation, or specialized requirements demand custom engineering approach delivering maximum value despite significant investment.

Decision Criteria: Custom vs. Standard

Systematic decision framework evaluates multiple factors determining whether custom or standard design optimally serves specific application. Balancing technical requirements, business objectives, and economic constraints ensures appropriate choice.

Technical Requirements Assessment

Functional Adequacy: Primary consideration examines whether standard configurations adequately meet functional requirements. Questions include: Does standard button layout support required user tasks efficiently? Do standard tactile characteristics (force, travel, feedback) suit intended users and usage patterns? Do standard materials and environmental protection match operating environment? Does standard circuit configuration accommodate electrical requirements? If standard designs adequately fulfill all functional requirements, custom development may represent unnecessary complexity and cost. However, if functional gaps exist—required button arrangement unavailable in standard configurations, specialized tactile or environmental performance needed, unique integration requirements—custom design necessity becomes clear.

User Experience Optimization: Beyond basic functionality, consider whether custom optimization meaningfully improves user experience. Will custom button placement optimized for specific tasks improve operation efficiency or reduce errors? Does custom tactile tuning (force, travel, snap ratio) enhance user satisfaction or reduce fatigue during extended use? Do custom graphics and branding create more intuitive, learnable interface or stronger product identity? Quantifiable user experience benefits—measurable error rate reduction, task completion time improvement, user satisfaction score increases—justify custom investment even when standard designs function adequately. Applications where user experience significantly impacts product success (medical devices affecting clinical workflow, consumer products in competitive markets, professional equipment where operator efficiency drives value) benefit substantially from UX-optimized custom designs.

Integration and Mechanical Fit: Evaluate physical integration requirements and constraints. Does product enclosure design accommodate standard switch sizes and mounting? Can standard connector types and locations integrate with product electronics and internal layout? If product industrial design or packaging constraints demand specific switch outline shape, mounting configuration, or connector routing, custom design becomes necessary regardless of functional adequacy. Conversely, if product designed without predetermined switch specifications, adapting product to accommodate standard switch simplifies development and reduces cost versus customizing switch to unusual constraints.

Business and Strategic Factors

Competitive Differentiation Requirements: Assess whether interface design influences competitive positioning and purchase decisions. Products competing primarily on price in commoditized markets may tolerate generic standard interfaces focusing differentiation elsewhere (features, quality, service). Products commanding premium pricing or competing on user experience quality benefit from custom interfaces communicating attention to detail and quality. Consumer electronics, medical devices, professional equipment, and products where user interaction significantly influences brand perception justify custom design investment creating differentiation competitors using standard switches cannot match. Business strategy analysis determines whether interface differentiation delivers sufficient competitive advantage warranting custom development investment.

Time-to-Market Pressure: Development timeline constraints strongly influence custom-versus-standard decisions. Projects with aggressive launch deadlines (trade show demonstrations, seasonal market windows, competitive response urgency) may require standard switches delivering immediate availability despite functional or experiential compromises. Custom development timelines (8-12+ weeks for complete development including prototyping and validation) may prove incompatible with urgent schedules. However, if timeline permits custom development, investing time for optimized design often delivers superior long-term outcomes versus hasty standard selection creating user experience debt requiring future redesign. Strategic timing analysis balances launch urgency against custom design benefits—sometimes phased approach using standard switches for initial launch then upgrading to custom design for subsequent production proves optimal compromise.

Intellectual Property and Supply Security: Custom designs create proprietary tooling and specifications providing supply security and potential IP protection. Custom tooling owned by customer (or assigned exclusively) prevents identical switches appearing in competitor products. Custom specifications and supplier relationships can create switching costs and supply assurance. Standard switches offer no exclusivity—competitors access identical parts potentially reducing differentiation. Applications where interface design represents protectable intellectual property or where supply security is critical may favor custom development. Conversely, commodity applications or situations where multi-source capability outweighs exclusivity may prefer standard switches facilitating supplier diversity.

Economic and Volume Considerations

Production Volume Thresholds: Production volume fundamentally determines custom development economic viability. Low volumes (<500-1,000 annual units) rarely justify custom tooling—per-unit tooling cost burden excessive. Medium volumes (1,000-5,000 units) create borderline cases—minimal customization may justify at lower end of range, moderate customization at higher volumes. High volumes (>5,000-10,000 units) increasingly favor custom development as per-unit tooling cost amortizes to negligible levels while custom optimization benefits accumulate across all units. Volume analysis must consider multi-year production horizons—single-year volumes may appear low, but 5-10 year product lifespans accumulate substantial total volumes potentially justifying custom investment.

Price Sensitivity and Budget Constraints: Product price points and margin structures influence customization decisions. High-margin products (medical devices, professional equipment, premium consumer products) tolerate higher per-unit costs enabling custom development investment. Low-margin commodity products demand minimal per-unit costs potentially precluding custom tooling investment unless volumes sufficient to amortize completely. Startup or small companies with constrained budgets may require standard switches preserving capital for other development priorities despite custom design preferences. Economic constraints analysis establishes affordable development budget and acceptable per-unit cost premiums guiding design approach selection.

Total Cost of Ownership: Comprehensive economic analysis considers total lifecycle costs beyond initial development investment. Custom designs optimized for user experience may reduce support costs (fewer user errors and support calls), improve throughput (more efficient operation), or reduce training requirements (intuitive interface). Custom environmental protection or reliability engineering may extend product lifespan or reduce warranty costs. Custom integration optimizing assembly may reduce production labor. Total cost analysis quantifies these downstream economic impacts potentially revealing custom design delivering superior economics despite higher initial investment. Conversely, standard switches minimizing upfront costs may incur higher downstream costs (support, warranty, redesign) suggesting custom investment would deliver better total value.

Cost Analysis and Break-Even Points

Quantitative economic analysis determines volumes where custom development investment becomes cost-effective. Understanding cost components and break-even calculations enables data-driven custom-versus-standard decisions.

Cost Component Breakdown

Standard Switch Costs: Standard membrane switches typically cost $3-15 per unit depending on size, complexity, and quantity. Simple 4-8 button arrays with basic graphics cost $3-6 in moderate quantities (500-2,000 units). Complex keypads or multi-function panels range $8-15. Pricing declines modestly with volume—1,000 unit quantity might price $6.00 each, 5,000 units $5.20, 10,000 units $4.80 representing 15-20% reduction across order magnitude volume increase. Standard switch costs include materials, manufacturing labor, overhead, and supplier profit margin. No development costs for truly standard configurations; minimal development ($300-800) for custom graphics on standard layout represents one-time cost amortized across production quantity.

Custom Switch Development Costs: Custom development incurs one-time tooling and engineering investment before any production units. Typical cost breakdown includes overlay cutting dies ($800-2,500 depending on complexity and size), graphics screens or digital printing setup ($400-1,500 for multi-color printing), dome placement fixtures if needed ($300-1,200), engineering and design ($800-2,500 for moderately complex designs, $2,000-5,000 for sophisticated custom development), prototypes and sampling ($300-800 for initial samples and revisions), and testing and validation ($200-800 for formal qualification). Total development costs range from $2,500-5,000 for minimal customization to $5,000-12,000 for comprehensive custom engineering. These are one-time non-recurring expenses independent of production quantity.

Custom Switch Production Costs: Custom switch unit production costs typically run 5-25% higher than equivalent standard designs—materials identical or similar, but custom configurations may require additional manufacturing steps, more careful handling, or specialized assembly processes reducing efficiency. Custom circuit layout or unusual constructions may increase scrap rates during process optimization. For first production runs, custom switch unit costs might be $5.50 (versus $4.80 standard equivalent), declining to $4.90-5.10 as manufacturing optimizes. The per-unit cost premium diminishes as production volumes increase and processes mature—high-volume custom production (>20,000 annual) may approach standard pricing as manufacturing learning curve and volume purchasing power offset customization complexity.

Break-Even Analysis

Break-Even Calculation Methodology: Break-even volume determines production quantity where custom total cost equals standard total cost. Formula: Break-Even Volume = Custom Development Cost ÷ (Standard Unit Cost - Custom Unit Cost). Example: Custom development costs $4,000, standard switches cost $6.00 each, custom switches cost $5.50 each. Break-even = $4,000 ÷ ($6.00 - $5.50) = 8,000 units. Below 8,000 total units, standard switches cost less; above 8,000 units, custom switches deliver lower total cost. This simple analysis ignores time value of money (custom investment occurs upfront, savings accumulate over production period) and downstream value factors (improved user experience, reduced support costs) but provides baseline economic comparison.

Sensitivity Analysis: Break-even highly sensitive to assumptions—small variations in cost estimates significantly shift break-even volume. Conservative analysis tests range of assumptions identifying robust decisions. If custom development might cost $3,000-5,000 and per-unit cost premium ranges $0.30-0.70, break-even varies from 4,300 to 16,700 units—vastly different implications. Sensitivity analysis reveals decision confidence—if break-even ranges from 3,000-5,000 units across reasonable assumption range while planned volume is 15,000 units, custom development clearly justified. If break-even ranges from 2,000-25,000 units while planned volume 5,000 units, decision uncertainty suggests deeper analysis or risk mitigation (phased approach, starting standard then migrating to custom if volume materializes).

Multi-Year Volume Aggregation: Product lifespans typically span multiple years—break-even analysis should aggregate total lifecycle volume not just first-year production. Product producing 2,000 units annually appears low-volume in single-year view, but 5-year lifecycle totals 10,000 units potentially justifying custom development. Multi-year analysis must discount for time value of money—$4,000 custom investment today delivers savings over 3-5 years requiring net present value calculation. Conservative approach might require 18-24 month payback on custom investment—development cost recovered within 2 years through production cost savings or demonstrable revenue benefits justifying longer payback periods.

Beyond Simple Break-Even

Value-Added Benefits Quantification: Custom designs may deliver quantifiable benefits beyond direct unit cost savings. Improved user experience reducing support calls—if custom interface reduces support calls 20% saving $2 per unit in support costs, this value adds to cost savings calculation potentially reducing break-even volume 40-60%. Faster user task completion improving throughput—medical device enabling 10% faster procedure completion creates tangible value for customers justifying premium pricing or volume capture. Reduced error rates preventing costly mistakes, enhanced durability extending product life, or improved aesthetics supporting premium pricing all represent quantifiable value potentially outweighing simple unit cost considerations. Comprehensive value analysis assigns economic value to these benefits incorporating into break-even calculation presenting complete picture of custom development return on investment.

Strategic Value Considerations: Some custom development benefits resist easy quantification but deliver strategic value. Brand differentiation creating market perception of quality and innovation, competitive positioning preventing "me-too" comparisons with competitors using standard switches, intellectual property creation through proprietary designs, design excellence awards or recognition enhancing brand reputation. While difficult to assign precise economic value, strategic benefits may justify custom investment even when pure financial break-even analysis marginal. Business judgment weighs strategic value against financial investment determining overall justification.

Risk-Adjusted Economics: Custom development introduces risks absent with standard switches—development timeline overruns potentially delaying product launch (opportunity cost), design issues requiring revision and rework (additional cost and delay), production yield challenges initially reducing gross margins. Risk-adjusted analysis incorporates probability-weighted cost of these risks. If 15% probability of 4-week launch delay costing $20,000 opportunity cost, risk-adjusted custom development cost increases $3,000. Conversely, standard switches carry user experience risks—interface inadequacy creating support issues or user dissatisfaction. Balanced risk analysis considers both custom development execution risks and standard switch functional/experiential risks enabling informed decision accounting for uncertainties.

Customization Options and Capabilities

Understanding available customization options across different membrane switch aspects enables targeted customization focusing investment on highest-value modifications while accepting standard approaches where adequate.

Layout and Configuration Customization

Button Arrangement and Sizing: Custom layouts optimize button placement for specific tasks and user ergonomics. Button positioning mirrors typical hand position and finger reach for target users—frequently-accessed controls positioned for easy reach without hand movement, button spacing prevents accidental adjacent actuation, button grouping reflects logical task flow. Button size variation emphasizes hierarchy—primary functions receive larger targets (12-20mm), secondary controls smaller (8-12mm), creating intuitive visual and tactile function importance communication. Custom layouts accommodate left-hand, right-hand, or ambidextrous operation as required. Gaming controllers, medical devices, industrial equipment, and professional tools benefit substantially from ergonomically-optimized custom button arrangements improving operation efficiency and reducing errors.

Outline Shape and Form Factor: Custom die-cutting creates arbitrary outline shapes matching product industrial design or packaging constraints. Rectangular, oval, circular, or completely free-form outlines conform to product aesthetics and available mounting areas. Cutouts accommodate displays, mounting bosses, ventilation, or other product features. Multiple membranes integrated in single assembly, folded or multi-plane configurations fitting complex 3D spaces. Outline customization enables seamless integration with product design rather than constraining product around standard rectangular switch. Die-cutting tooling costs $800-2,500 depending on size and complexity—relatively modest investment enabling significant integration and aesthetic benefits.

Connector Configuration: Custom connector placement, type, and pinout match product electronics architecture. Connector exit location optimized for cable routing within enclosure, connector type selected for mating with product electronics (ZIF connectors for easy assembly, pin headers for PCB mounting, overmolded cable for permanent attachment), pin assignment matches product circuit board layout minimizing routing complexity. Custom circuit layout creates optimal trace routing reducing electrical resistance or enabling complex switching matrices. Connector customization facilitates clean product integration versus adapting product electronics to standard switch connector limitations.

Tactile Customization

Custom Actuation Force: Specifying custom metal dome forces enables precise tactile character tuning. Standard catalog domes typically available in 50-100 gram increments (180g, 250g, 350g, 500g); custom force specification achieves intermediate values (220g, 300g, 425g) matching specific user requirements or ergonomic studies. Different forces across button array creates tactile hierarchy—light forces (180-220g) for frequently-used controls enabling rapid comfortable actuation, heavier forces (350-450g) for critical or infrequent functions preventing accidental activation. Custom force requires dome manufacturer development ($800-2,000 tooling) and minimum quantities (typically 5,000-10,000 domes) but enables optimized tactile character unavailable with standard offerings.

Snap Ratio and Travel Optimization: Custom dome geometry, overlay thickness, and embossing height tune snap ratio (tactile definition) and travel distance. High snap ratio (>60%) creates crisp, distinct tactile feedback ideal for data entry or professional equipment. Lower snap ratio (<40%) produces softer, more gradual tactile sensation suitable for gentle-touch consumer applications. Travel distance optimization balances tactile clarity (longer travel enhances feedback perception) against low-profile requirements (minimal travel reduces assembly thickness). Custom tactile engineering through prototyping and testing identifies optimal force-travel characteristics for specific user populations and usage patterns.

Materials and Construction Customization

Premium Overlay Materials: Custom designs access full overlay material spectrum. Thick polycarbonate (0.030"-0.040") provides maximum abrasion resistance for public kiosks or harsh industrial environments. Specialized films offer chemical resistance (resisting cleaning agents, solvents, or industrial fluids), optical properties (anti-glare, anti-fingerprint coatings), or unique textures (soft-touch, rubberized, metallic). Rigid overlays on flexible base combines durability with circuit flexibility. Automotive-grade materials withstand extreme temperature cycling and UV exposure. Medical-grade materials meet biocompatibility and sterilization requirements. Material customization precisely matches environmental exposure and performance requirements rather than compromising with general-purpose standard materials.

Advanced Circuit Technologies: Circuit customization optimizes electrical performance or cost. Silver flex circuits (versus standard silver-silver chloride) deliver lower resistance for sensitive electronics or longer circuit tails. Carbon ink circuits reduce material costs for economy applications. Rigid-flex constructions integrate membrane circuit with rigid PCB sections. Shielded circuits prevent electromagnetic interference. Conductive adhesives or specialized contacts optimize electrical reliability. Circuit customization addresses specific electrical architecture requirements or cost optimization opportunities unavailable with standard single-circuit-type approach.

Environmental Sealing: Custom sealing designs achieve application-specific IP ratings and environmental protection. IP65-IP67 sealing through custom gasket selection and perimeter seal design, chemical-resistant seal materials for harsh exposure, high-temperature adhesives and materials for extreme environments, custom vent integration for pressure equalization, potted or encapsulated constructions for ultimate protection. Sealing customization ensures environmental protection precisely matches operating conditions rather than over-specifying (wasting cost) or under-specifying (risking failures) with standard environmental protection approaches.

Graphics and Aesthetic Customization

Unlimited Color and Graphic Capabilities: Custom graphics enable complete creative freedom. Full color printing (screen printing multi-color, digital UV printing full CMYK), photographic quality images, gradient fills and complex artwork, brand-specific colors matched to PMS standards, metallic or specialty inks. Selective textures create visual and tactile interest—glossy legends on matte background, textured areas for grip, smooth areas for aesthetics. Graphics integration with embossing creates 3D visual depth. Transparent window areas over displays, selective light blocking for backlit designs creating dramatic appearance changes between lit and unlit states. Graphics customization enables brand expression and sophisticated visual design impossible with limited standard graphic capabilities.

Premium Surface Treatments: Specialized overlay surface treatments create distinctive aesthetics or functional benefits. Anti-glare coatings improve visibility in bright environments, anti-fingerprint treatments maintain clean appearance, hard coatings enhance abrasion resistance beyond base material properties. Soft-touch or rubberized coatings create pleasant tactile feel. Selective coatings—glossy clear over graphics with matte background, or reversed pattern. Dead-front appearance (opaque when unlit, graphics visible when backlit). Surface treatment customization differentiates premium products or optimizes functional performance for specific operating environments.

Design and Development Process

Understanding custom membrane switch development process stages, timelines, and deliverables enables effective project planning and successful execution. Systematic approach minimizes iterations and prevents costly late-stage changes.

Requirements Phase

Comprehensive Specification Development: Successful custom development begins with detailed requirements documentation. Requirements should specify dimensional constraints (available mounting area, maximum thickness, clearance limitations, connector location constraints), electrical specifications (circuit resistance limits, contact current/voltage ratings, connector type and pinout, any special electrical requirements like ESD protection or shielding), environmental requirements (operating temperature range, IP rating needed, chemical exposure, UV resistance, cleaning methods), tactile requirements (desired actuation force range, travel distance, tactile character preferences), cycle life expectations (minimum actuation cycles required), aesthetic requirements (brand colors, graphic style, surface finish), regulatory compliance needs (UL, medical device standards, automotive requirements), and any other application-specific constraints or preferences. Incomplete requirements lead to misalignment, redesign cycles, and schedule delays—investing time in thorough upfront specification prevents far more expensive downstream corrections.

Preliminary Feasibility Assessment: Before committing to full development, preliminary feasibility review identifies potential challenges or constraints. Manufacturer reviews requirements assessing technical feasibility (Can specified performance be achieved? Are requirements mutually conflicting?), timeline implications (Do requirements or quantity dictate specific processes affecting schedule?), cost implications (Do requirements necessitate premium materials or processes substantially affecting pricing?), and regulatory or compliance considerations (Do certifications require specific approaches or extended validation?). Feasibility assessment may identify requirement adjustments enabling more cost-effective or timely development while still meeting core needs—alternative materials achieving similar performance at lower cost, requirement relaxation simplifying development without compromising functionality, or phased approach deferring some requirements to later product generations.

Conceptual Design Phase

Preliminary Layout Development: Initial design phase creates rough layouts and concept sketches exploring design approaches. Designers typically develop 2-3 alternative concepts demonstrating different layout philosophies, material approaches, or construction methods. Concepts presented as simple drawings or renderings showing button arrangement, general size and shape, connector placement, and key construction decisions. Preliminary mechanical drawings indicate overall dimensions and mounting approach. Early-stage concepts enable direction-setting without investing in detailed engineering—customer provides feedback on preferred layout approach, graphic style direction, and construction philosophy before detailed design proceeds. Concept review typically takes 1-2 weeks including initial development and customer feedback iteration.

Material and Construction Selection: Concept phase establishes baseline material and construction approach. Decisions include overlay material type and thickness balancing durability, tactile, and cost requirements, circuit material and configuration, tactile feedback method and dome specifications, adhesive systems for lamination and mounting, environmental sealing approach, and connector type. Material selection considers trade-offs—thicker overlays provide durability but reduce tactile clarity and increase cost, premium circuit materials improve electrical performance but add expense, advanced sealing enhances environmental protection but complicates assembly. Concept phase crystallizes material decisions enabling cost estimation and detailed engineering to proceed efficiently.

Detailed Engineering Phase

Complete Design Documentation: Detailed engineering creates production-ready specifications. Deliverables include overlay artwork files (graphics provided in vector format with color specifications, registration marks, dimension verification), overlay die-cut specifications (outline shape, holes, cutouts with tolerances), circuit layout drawings (trace routing, contact locations, connector pinout), dome selection and placement specifications (dome part numbers, force ratings, precise placement coordinates), assembly stack-up drawings (layer sequence, adhesive specifications, thickness callouts), connector specifications (type, supplier part number, attachment method), environmental sealing details (gasket specifications, seal locations and widths), dimensional drawings with full tolerancing, and electrical schematics showing circuit connectivity. Complete documentation enables prototype fabrication, serves as production reference, and provides customer approval documentation before tooling investment.

Prototype Development: Detailed designs translate into physical prototypes for evaluation. Initial prototypes may use prototype-specific methods—digital printing graphics instead of screen printing (faster, lower cost for small quantities), manual assembly versus production tooling, expedited processes prioritizing speed over cost. Prototype quantities typically 3-10 units enabling functional testing, user evaluation, mechanical fit verification, and destructive testing validation. Prototype testing identifies design refinements—tactile force adjustment, graphic modifications, mechanical fit corrections, assembly process improvements. Prototype iteration may cycle 1-3 times converging on final design before production tooling commitment. Prototype phase typically requires 3-5 weeks including build time, evaluation, and refinement iterations.

Validation and Production Release

Formal Design Validation: Final prototype undergoes systematic validation testing confirming specification compliance. Validation tests include dimensional verification (confirming drawings accuracy, mechanical fit), electrical testing (circuit resistance, insulation resistance, contact reliability), tactile testing (force-displacement measurement, actuation consistency), environmental testing (temperature exposure, humidity conditioning, IP rating validation if applicable), cycle life testing (accelerated actuation confirming lifespan projections), and any regulatory testing (UL submission, medical device biocompatibility, automotive qualifications). Formal test reports document validation results providing evidence design meets requirements and customer approval for production release. Validation typically requires 2-4 weeks depending on test program comprehensiveness.

Production Tooling and First Article: Design approval triggers production tooling fabrication. Tooling includes overlay cutting dies (steel-rule dies for high-volume production), graphics screens (if screen printing) or digital printing setup, dome placement fixtures (for automated or semi-automated assembly), assembly fixtures (alignment and lamination tooling), and testing fixtures (electrical test adapters, functional test setups). Tooling fabrication requires 3-5 weeks typically. First production run using production tooling creates "first article" inspection samples verifying tooling accuracy and production process capability. First article inspection compares production units to engineering drawings and validation samples confirming production quality matches development intent. Production release follows first article approval authorizing ongoing production.

Timeline and Lead Time Considerations

Development and production timelines significantly differ between custom and standard membrane switches. Understanding timeline implications enables realistic project planning and schedule-driven design decisions.

Standard Switch Timelines

Stock Item Availability: Truly standard configurations maintained in manufacturer inventory deliver fastest possible timelines. Stock switches ship within 3-7 business days from order placement—essentially immediate availability limited only by order processing and shipping logistics. Stock availability suits urgent replacement needs, rapid prototype builds requiring functional switches for system testing, or small-quantity projects where standard meets needs. However, stock inventory typically limited to highest-volume generic configurations—numeric keypads, basic function arrays—with limited customization options.

Modified Standard Lead Times: Semi-standard designs with custom graphics on standard construction deliver in 2-4 weeks. Timeline includes artwork processing and approval (3-5 days), graphics screen fabrication or digital printing setup (5-7 days), production scheduling and material procurement (3-5 days), manufacturing build (3-5 days), quality inspection and packaging (2-3 days), and shipping (varies by destination and method). Four-week timeline typical for moderate complexity; simple graphics on basic layouts may compress to 2 weeks, complex multi-color graphics or quality hold points extend to 4-5 weeks. Modified standard approaches balance relatively rapid availability with meaningful customization—suitable for projects requiring modest branding or layout adaptation without timeline accepting full custom development.

Custom Development Timelines

Complete Development Cycle: Fully custom membrane switch development from requirements through production-ready units typically requires 8-12 weeks. Timeline breakdown: requirements definition and preliminary review (1 week), conceptual design and customer review (1-2 weeks), detailed engineering and design documentation (2 weeks), prototype fabrication and initial evaluation (2-3 weeks), design refinement and second prototype iteration if needed (1-2 weeks), validation testing and formal qualification (2-3 weeks), production tooling fabrication (3-4 weeks concurrent with validation), and first production run and first article inspection (1-2 weeks). Timeline variations depend on design complexity, number of prototype iterations required, regulatory testing scope, and tooling complexity. Aggressive schedules with simple designs, minimal iterations, and expedited tooling may compress to 6-7 weeks. Complex designs requiring multiple iterations, extensive testing, or specialized tooling may extend to 14-16 weeks.

Fast-Track Development Options: When custom design necessary but timeline critical, expedited development compresses schedule at premium cost. Fast-track approaches include expedited prototyping using rapid methods (digital printing, laser cutting, overnight shipping) potentially delivering samples in 5-7 days versus 2-3 weeks, concurrent activities (starting tooling fabrication before final validation complete, preparing production based on high-confidence prototype design), expedited tooling (premium charges for rush fabrication compressing 4-week tooling to 2 weeks), and compressed review cycles (daily progress updates, immediate feedback enabling continuous progress versus awaiting weekly review meetings). Expedited development may compress timeline 30-40% (12-week standard program to 7-8 weeks fast-track) but typically adds 25-50% cost premium through rush charges, overtime labor, and expedited shipping. Fast-track justifies when early market entry value or urgent product launch window exceeds expedite premium costs.

Schedule Risk Management

Common Timeline Delays: Understanding typical delay sources enables proactive mitigation. Frequent delay factors include incomplete or changing requirements extending design phase (customer feedback identifying new needs mid-development requiring redesign), extended prototype evaluation (customer testing revealing issues necessitating additional iteration), design challenges requiring additional engineering (unexpected technical difficulties solving layout, tactile, or integration problems), tooling delays (tooling vendor capacity constraints or fabrication complexity), and validation testing failures (designs failing qualification requiring correction and re-test). Each prototype iteration adds 2-3 weeks; tooling delays extend 1-4 weeks; validation failures potentially add 3-6 weeks if significant redesign required. Schedule risk mitigation includes thorough upfront requirements (preventing mid-development changes), early prototype feedback (rapid customer evaluation preventing multiple slow iterations), proven design approaches (leveraging established solutions reducing technical risks), and qualified supplier selection (capable manufacturers with capacity and track record).

Timeline-Driven Design Decisions: When timeline critical, design decisions may favor proven approaches over optimal solutions. Selecting standard materials and constructions with known performance reduces development risk and time versus experimental approaches requiring extended validation. Accepting standard connector types and locations simplifies design versus custom integration. Deferring advanced features (complex backlighting, sophisticated sealing) to later product generations enables faster initial launch with enhancement plan. Phased development—launching with modified-standard switches delivering in 4 weeks, then migrating to optimized custom design for ongoing production—balances timeline urgency with long-term optimization. Timeline-driven decisions require trade-off discipline—understanding what compromises acceptable versus non-negotiable ensuring schedule achieved without unacceptable functional sacrifice.

Production Volume Impact on Economics

Production volume fundamentally alters custom-versus-standard economics through tooling amortization, pricing leverage, and long-term supply considerations. Volume-appropriate decisions optimize total program economics.

Low-Volume Economics (< 1,000 Annual Units)

Standard Switch Preference: Low production volumes strongly favor standard switches minimizing upfront investment. Custom development cost of $3,000-5,000 creates $3-5 per-unit burden at 1,000 units, $6-10 at 500 units, $15-25 at 200 units—dramatic cost premiums difficult to justify. Standard switches at $5-12 each deliver functional interface without development investment preserving capital for other product priorities. Low-volume applications—specialized equipment, niche markets, pilot production, service parts—typically accept standard configurations or minimal customization (graphics only) avoiding substantial tooling costs. Exception cases where custom design delivers quantifiable value (error reduction saving $20 per unit, premium pricing supported by differentiated interface capturing $30 additional revenue) can justify development investment even at low volumes through value-capture exceeding tooling cost.

Minimizing Customization Investment: When customization necessary at low volumes, aggressive cost minimization focuses investment on highest-impact modifications. Graphics-only customization ($300-800 total development) enables branding and basic interface optimization at manageable cost. Simple die-cut outline modification ($800-1,200) allows product integration without comprehensive custom development. Using standard materials, constructions, and tactile components while customizing only layout and graphics balances differentiation against investment. Careful specification defining must-have versus nice-to-have customizations prevents gold-plating—focusing limited budget on critical differentiation while accepting standard approaches elsewhere.

Medium-Volume Economics (1,000-10,000 Annual Units)

Transition Zone Analysis: Medium volumes create interesting economics where custom development begins justifying but standard remains viable. At 3,000 annual units, $4,000 custom development amortizes to $1.33 per unit—modest premium easily offset by 10-20% unit cost reduction through custom optimization or $2-3 value-added benefits (reduced support, improved throughput). At this volume range, decision depends on specific value proposition—if custom design delivers meaningful user experience improvements, competitive differentiation, or cost optimization opportunities, development investment justified. If standard adequately serves needs without significant compromises, preserving $4,000 development budget for other purposes may prove wiser allocation.

Moderate Customization Optimization: Medium volumes suit moderate customization approaches balancing optimization against investment. Custom layout and graphics ($2,000-3,500 development) delivering substantially improved user interface justify at 2,000-3,000 units. Premium overlay materials or specialized environmental protection ($3,000-5,000 development) justify at 5,000+ units when performance demands warrant. Full custom engineering with comprehensive optimization ($5,000-8,000+ development) requires 8,000-10,000+ volume or very high per-unit value capture. Medium-volume optimization focuses development investment on aspects delivering highest value—perhaps custom layout and graphics while accepting standard tactile and circuit configurations, or custom environmental sealing while using standard layout, targeting investment where differentiation or performance value greatest.

High-Volume Economics (> 10,000 Annual Units)

Custom Development Strongly Favored: High volumes make custom development economically compelling. At 15,000 annual units, $6,000 custom development amortizes to $0.40 per unit—negligible versus potential per-unit savings or value benefits. Custom optimization reducing unit cost $0.50 (through material optimization, construction efficiency, or volume leverage) delivers $7,500 annual savings exceeding development cost in single year. Custom design improving user experience reducing support costs $2 per unit creates $30,000 annual value far exceeding development investment. High-volume economics strongly incentivize custom development—even modest per-unit benefits generate substantial total value justifying comprehensive custom engineering.

Continuous Improvement Investment: High volumes justify ongoing design optimization and refinement. After initial custom development, production experience may identify further improvement opportunities—assembly efficiency enhancements reducing labor, material substitutions reducing costs, quality improvements reducing scrap. At high volumes, engineering investment of $2,000-4,000 optimizing manufacturing process delivering $0.20 per-unit savings generates $3,000-6,000 annual value at 15,000 volume (assuming 3-4 year remaining product life) justifying continuous improvement investment. High-volume programs should budget ongoing engineering maintaining design optimization rather than treating custom development as one-time activity.

Volume Uncertainty and Risk

Managing Volume Forecast Risk: Production volume forecasts carry uncertainty—new products may exceed or fall short of projections. Volume risk management strategies include conservative custom development proceeding only when volume confidence high (validated customer demand, proven market, established product family), phased approach starting with standard or minimal customization then upgrading to comprehensive custom design when volume validates, tooling cost recovery in pricing (adding $1-2 per-unit margin recovering development cost over first 5,000 units providing break-even protection if volumes disappoint), and flexible designs enabling future upgrades (standard initial switches designed for easy migration to custom when volume justifies). Volume uncertainty should inform decision conservatism—higher uncertainty argues for lower upfront custom investment, high confidence enables aggressive custom development.

Engineering and Technical Considerations

Technical factors beyond pure cost-benefit analysis influence custom-versus-standard decisions. Understanding engineering implications ensures technically sound choices supporting product success.

Design Complexity and Feasibility

Technical Difficulty Assessment: Some custom requirements prove technically challenging requiring specialized capabilities, materials, or processes. Complex requirements include very tight tolerances (<±0.005" on critical dimensions), extreme environmental exposure (temperature extremes beyond -40°C to +85°C, aggressive chemical resistance), unusual geometries (very small keys <5mm, very large assemblies >300mm dimension, complex 3D contours), specialized electrical performance (very low resistance <5 ohms over long tails, high-voltage isolation >1000V, RF shielding), or novel tactile mechanisms (custom haptic actuators, force-sensing, variable tactile). Technically demanding custom designs require manufacturer with proven capabilities, may necessitate extended development validating feasibility, and carry higher risk of design challenges extending schedule or requiring specification compromise. Technical complexity argues for standard approaches when feasible, or selection of highly capable custom manufacturer when advanced requirements essential.

Manufacturability Optimization: Custom designs should incorporate design-for-manufacturing principles enabling efficient, high-quality production. Manufacturability considerations include avoiding very small features prone to registration or handling difficulties, using standard material thicknesses and dimensions enabling efficient procurement, specifying tolerances appropriately tight for function but not unnecessarily constrained, designing self-locating features facilitating assembly alignment, minimizing manual operations preferring automated or semi-automated processes, and incorporating inspection and test access points. Manufacturer input during design phase identifies manufacturability concerns enabling design optimization. Well-designed custom switches manufacture as efficiently as standards; poorly-designed custom switches create yield losses, handling difficulties, and quality issues partially offsetting volume-based cost advantages.

Supply Chain and Sourcing

Supplier Qualification and Selection: Custom development creates dependency on selected manufacturer possessing design tooling and process knowledge. Supplier selection criteria include technical capability matching design requirements, quality system appropriate for application (ISO 9001, medical device QMS, automotive IATF 16949), capacity supporting volume requirements and growth, financial stability ensuring long-term support, responsiveness and communication quality, and competitive pricing. Qualified supplier selection mitigates risks—capable manufacturers deliver on schedule with high quality, questionable suppliers create delays, quality issues, and potential redesign needs. Standard switches offer multi-source flexibility—if one supplier proves unsatisfactory, alternate sources available. Custom designs should consider supplier relationship importance and qualification rigor accordingly.

Intellectual Property and Tooling Ownership: Custom tooling ownership affects supply flexibility and IP protection. Customer-owned tooling (customer pays tooling cost, owns dies and screens) provides maximum flexibility—can move production to alternate supplier if needed, prevents supplier using designs for competitors. Supplier-owned tooling (tooling cost amortized in unit pricing) reduces upfront cost but creates supplier dependency. Exclusive agreements prevent supplier producing for competitors but don't provide portability. IP and tooling ownership structures should match application criticality and competitive sensitivity—commodity applications may accept supplier-owned tooling for cost benefits, proprietary designs demand customer ownership protecting competitive position.

Regulatory and Compliance Factors

Industry-Specific Requirements: Some industries impose specific requirements influencing custom-versus-standard decisions. Medical device applications require design control procedures, biocompatibility validation, and formal design verification documentation—custom development must incorporate these requirements potentially extending timeline and cost. Automotive applications specify quality systems (IATF 16949), environmental testing (AEC-Q100 component qualification), and PPAP submission—adding development burden. Military/aerospace applications demand extensive qualification, documentation, and potentially source inspection. Standard switches with established regulatory approvals (UL listing, medical device master files) reduce compliance burden—custom designs must recreate validation adding cost and time. Applications in regulated industries should factor compliance requirements into custom-versus-standard economics and timeline analysis.

Risk Assessment and Mitigation

Custom and standard switches present different risk profiles. Systematic risk assessment and mitigation strategies minimize probability and impact of potential issues.

Custom Development Risks

Schedule Risk: Custom development timelines subject to delays from design iterations, technical challenges, tooling issues, or validation failures. Schedule delays risk missing market windows, delaying revenue, or enabling competitor preemption. Mitigation strategies include realistic timeline planning with contingency buffers (15-20% schedule margin), aggressive early prototype evaluation accelerating design iteration, proven design approaches reducing technical risk, qualified supplier selection minimizing execution risk, and timeline-driven design decisions when necessary accepting proven solutions over optimal but risky approaches. Critical launch deadlines may warrant standard switches ensuring timeline certainty despite functional compromises, with custom development following for production optimization.

Cost Overrun Risk: Custom development costs may exceed estimates from scope expansion, technical challenges requiring additional engineering, iteration beyond planned cycles, or tooling complexity. Cost overruns absorb budget allocated elsewhere or erode margins if absorbed in product cost. Mitigation includes detailed upfront scoping and fixed-price quotations, change control discipline preventing scope creep, design reviews at concept stage before detailed engineering investment, and contingency budget (15-25% of estimated development cost) absorbing moderate variance. Fixed-price contracts with qualified suppliers transfer cost risk, though suppliers may include contingency premium in pricing.

Performance Risk: Custom designs may fail meeting performance targets—tactile feel not matching preferences, environmental protection inadequate, reliability issues emerging in field. Performance failures necessitate redesign and rework (cost, delay) or product compromises and field issues (support costs, reputation damage). Mitigation strategies include prototype testing and user validation before production commitment, conservative design margins exceeding minimum requirements providing buffer for variation, validation testing confirming specification compliance, and field trial or pilot production with feedback loop before volume production. Standard switches offer proven performance reducing this risk dimension.

Standard Switch Risks

Functional Inadequacy: Standard switches may prove inadequate for application creating user experience issues, functionality limitations, or integration compromises. Interface awkwardness creates user errors, inefficiency, or satisfaction issues potentially manifesting as support costs, returns, or negative reviews. Mitigation requires honest adequacy assessment—prototype testing with standard switches evaluating real usability, user feedback gathering on standard interface adequacy, and willingness to invest in custom development when standard clearly inadequate rather than forcing poor fit. Functional inadequacy often invisible until real user interaction—pilot production or beta testing with standard switches provides validation but may delay custom development decision.

Competitive Disadvantage: Standard switches limit differentiation potentially creating competitive vulnerability—products using similar interfaces appear commoditized enabling competitor price pressure. Premium positioning or differentiation strategies may prove unsupported by generic interface. Mitigation includes market analysis assessing competitor interface approaches and differentiation importance, customer research validating whether interface differentiation influences purchase decisions, and strategic decision whether accepting competitive parity adequate or differentiation necessary. Some markets truly commoditized where interface differentiation provides minimal value—standard approaches adequate. Others highly competitive where differentiation critical—custom investment justified for strategic advantage.

Availability and Obsolescence: Standard switches depend on manufacturer continued production—product lines discontinued leave customers seeking alternates potentially requiring redesign. Long product lifecycles may outlive standard switch availability. Mitigation strategies include lifecycle inquiry when selecting standards (understand manufacturer production plans and commitment), alternative identification (validate backup sources for critical applications), and larger inventory purchases when discontinuation anticipated (buying multi-year supply if economical). Very long product lifecycles (10+ years) favor custom development with customer-owned tooling ensuring continued availability rather than dependence on manufacturer standard product continuity decisions.

Case Studies and Real-World Examples

Real-world examples illustrate successful custom-versus-standard decisions across diverse applications demonstrating decision methodology and outcomes.

Case Study 1: Medical Device - Custom Development Success

Application Background: Medical device startup developing portable patient monitoring system targeting hospital and home healthcare use. Device featured small touchscreen display with 8-button membrane switch array for critical function access without touchscreen navigation. Projected volume: 5,000 first-year units scaling to 12,000 annual by year three. Product positioning as premium clinical-grade device commanding $2,800 retail price with 45% gross margins target.

Decision Analysis: Initial evaluation considered standard 8-button array ($8.50 unit cost, immediate availability, minimal development cost). However, clinician feedback during requirements definition identified critical usability requirements—buttons must accommodate gloved operation (larger size, higher force, generous spacing), clinical functions needed clear tactile differentiation (varied actuation forces communicating function importance), IP65 environmental sealing required (repeated disinfectant spray exposure), and premium appearance expected for high-price device. Standard switches failed multiple requirements—button size/spacing too compact for gloved use, single actuation force across all buttons provided no tactile hierarchy, IP54 sealing inadequate for clinical disinfection protocols, basic aesthetics inappropriate for premium positioning.

Custom Development Approach: Custom development specified: enlarged buttons (15mm vs 10mm standard) with increased spacing (18mm center-to-center vs 12mm standard) accommodating gloved operation, varied actuation forces (220g for frequent functions, 350g for critical infrequent controls, 450g for emergency stop), comprehensive IP65 sealing with silicone gaskets and sealed connector, premium polycarbonate overlay (0.025" thick) with medical-grade materials, sophisticated graphics with color-coded function groups and clear iconography. Development cost $6,200, custom unit cost $11.80 (vs $8.50 standard). Timeline: 10 weeks custom development vs immediate standard availability.

Outcomes and Value: Custom switches delivered substantial value justifying investment. Usability testing showed 35% faster task completion and 40% error reduction versus standard interface mock-ups, clinician satisfaction scores 8.7/10 vs projected 6.2/10 for standard alternative, premium appearance supported positioning and pricing strategy. Development cost amortized to $1.24 per unit at first-year 5,000 volume, $0.52 at year-three 12,000 volume. Custom unit cost premium $3.30 offset by value—reduced support costs (fewer user errors), competitive differentiation supporting premium pricing, and clinical efficiency improving customer value proposition. Total program economics strongly favored custom development despite higher initial investment and unit cost. Product achieved market success with interface cited in customer reviews as differentiating quality factor.

Case Study 2: Consumer Appliance - Modified Standard Success

Application Background: Consumer appliance manufacturer developing mid-range coffee maker for competitive retail market targeting $89 retail price. Product required 6-button control interface for brew strength, cup size selection, timer, and basic functions. Projected volume: 45,000 first-year units. Market positioned as value-oriented with acceptable quality, competing against numerous similar products in crowded category.

Decision Analysis: Initial plan specified fully custom development creating distinctive branded interface differentiating in crowded market ($5,500 development cost, $4.80 unit cost, 8-week timeline). However, cost and timeline analysis revealed concerns—$5,500 development represented significant budget allocation for mid-range product in tight margin category, 8-week custom timeline risked missing seasonal retail window. Evaluation of semi-standard approach using manufacturer's standard 6-button layout with custom graphics showed $1,200 development (graphics screens only), $4.20 unit cost (volume pricing on standard configuration), 3-week delivery enabling retail deadline.

Modified-Standard Approach: Program proceeded with modified-standard approach customizing graphics on proven standard 6-button layout. Custom graphics incorporated brand colors, clear iconography, and product-specific labeling while accepting standard button arrangement and construction. Graphics investment $1,200 enabled brand expression and product-specific interface without full custom development cost and timeline. Unit cost $4.20 vs $3.80 target, but $0.40 premium deemed acceptable given development savings and timeline certainty.

Outcomes and Value: Modified-standard approach delivered successful outcome. Three-week delivery met retail schedule enabling seasonal placement critical for category. Graphics customization provided adequate brand differentiation and functional clarity—consumer research showed no significant preference difference between modified-standard and fully-custom mock-ups suggesting custom investment wouldn't meaningfully improve market performance. Development savings $4,300 allocated to other product priorities. Product achieved volume targets with interface adequacy confirmed by low support incident rates and acceptable customer reviews. Case demonstrated modified-standard optimally balancing differentiation, cost, and timeline for value-oriented consumer product in competitive market where full custom development provided limited incremental value.

Case Study 3: Industrial Equipment - Standard Switch Appropriate

Application Background: Industrial equipment manufacturer developing specialized calibration tool for niche metrology market. Product priced $12,000 targeting 150-200 annual unit sales. Device required basic 12-button control interface supplementing primary touchscreen control. Button functions straightforward—numeric entry, mode selection, confirmation/cancel.