Table of Contents

- Introduction

- Backlighting Technologies Overview

- LED Backlighting Systems

- Light Guide Film Design and Optimization

- Electroluminescent Backlighting

- Fiber Optic Illumination

- Design Considerations and Challenges

- Color and Brightness Management

- Power Consumption and Efficiency

- Environmental and Durability Factors

- Manufacturing and Assembly Integration

- Frequently Asked Questions

- Conclusion

Quick Answer: Backlit membrane switches utilize LED, electroluminescent (EL), or fiber optic technologies to illuminate graphics and indicators, achieving 20-500 cd/m² brightness with power consumption from 5-100mW per switch. LED backlighting dominates with 50,000+ hour lifespan, while EL offers uniform area lighting at 3,000-10,000 hours. Effective design requires proper light distribution (>80% uniformity), color consistency (ΔE<3), thermal management, and integration with switch layers maintaining tactile response and environmental sealing.

Backlighting transforms membrane switches from simple input devices into sophisticated user interfaces that function effectively in any lighting condition. Throughout my 15 years at JASPER developing backlit membrane switches for aerospace, medical, and automotive applications, I've witnessed the evolution from simple indicator lights to complex multi-color displays. This comprehensive guide explores all aspects of membrane switch backlighting, from fundamental technologies to advanced design optimization techniques.

Backlighting Technologies Overview

Understanding the characteristics of different backlighting technologies enables optimal selection for specific application requirements.

Technology Selection Criteria

Brightness requirements range from 20 cd/m² for indoor office environments to 500+ cd/m² for outdoor daylight visibility. Uniformity specifications typically demand >80% consistency across illuminated areas preventing hot spots or dark zones. Power consumption constraints particularly critical for battery-powered devices favoring LED efficiency. Environmental conditions including temperature (-40°C to +85°C), humidity, and vibration influence technology selection. Cost considerations balance initial component expense against lifetime operating costs including power and replacement.

Comparative Analysis

LED backlighting provides 50,000-100,000 hour lifespan with excellent efficiency of 100-150 lumens/watt. Electroluminescent technology offers uniform area lighting but limited 3,000-10,000 hour life expectancy. Fiber optic systems eliminate electrical components at switch location ideal for hazardous environments. Light guide films distribute LED point sources achieving uniform illumination with minimal thickness. Each technology presents unique advantages requiring careful evaluation against application requirements.

Emerging Technologies

Mini-LED arrays increase local dimming zones improving contrast and reducing power consumption. Micro-LED technology promises higher brightness and efficiency in thinner packages. Quantum dot films enhance color gamut achieving 95%+ NTSC coverage for display applications. OLED integration enables flexible, transparent lighting layers for advanced interfaces. Smart phosphors provide color-changing capabilities responding to temperature or electrical signals.

LED Backlighting Systems

LED technology dominates modern membrane switch backlighting due to superior efficiency, reliability, and design flexibility.

LED Selection and Specification

Surface-mount LEDs in 0603 to 1206 packages balance size with light output for most applications. High-brightness white LEDs achieve 20-40 lumens output suitable for daylight visibility. Color LEDs enable status indication with wavelengths from 470nm (blue) to 630nm (red). Viewing angle considerations range from 120° for general illumination to 30° for directed light. Forward voltage matching ensures uniform brightness in parallel configurations. Thermal characteristics determine maximum current and heat dissipation requirements.

Circuit Design and Control

Constant current drivers maintain uniform brightness despite voltage and temperature variations. PWM dimming from 1-100% enables brightness adjustment without color shift. Series-parallel configurations balance current sharing with voltage requirements. Protection circuits including TVS diodes prevent ESD damage to sensitive LEDs. Multiplexing reduces connection count for multi-zone backlighting applications. Temperature compensation maintains consistent brightness across operating range.

Integration Methods

Side-firing LEDs couple efficiently into light guides minimizing thickness. Direct backlighting places LEDs behind translucent overlays for localized illumination. Edge-lit designs distribute light through acrylic or polycarbonate light guides. Embedded LEDs within flexible circuits eliminate separate mounting requirements. Discrete LED mounting on rigid PCBs provides thermal management for high-power applications. Chip-on-board technology integrates bare LED dies directly onto substrates.

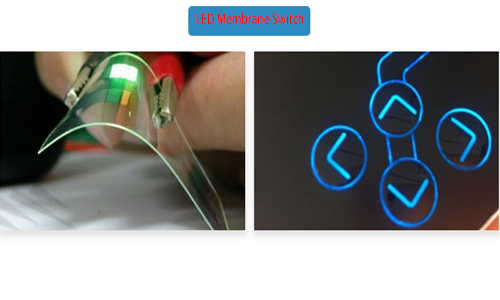

Light Guide Film Design and Optimization

Light guides transform point LED sources into uniform area illumination essential for professional backlit interfaces.

Light Guide Materials

Acrylic (PMMA) provides excellent optical clarity with 92% transmission and low cost. Polycarbonate offers superior impact resistance and temperature tolerance to 125°C. Silicone light guides accommodate extreme flexibility for conformable applications. Optical-grade materials minimize absorption losses maintaining high efficiency. UV-stabilized formulations prevent yellowing in outdoor applications. Thickness from 0.010" to 0.125" balances light distribution with space constraints.

Light Extraction Techniques

Laser etching creates precise micro-patterns controlling light extraction density and direction. Screen-printed dots vary in size and spacing compensating for distance from LED sources. Molded textures integrate extraction features during light guide formation. V-groove patterns direct light perpendicular to guide surface maximizing extraction efficiency. Gradient patterns compensate for light intensity fall-off achieving uniform output. Multi-layer extraction combines techniques for complex illumination requirements.

Optical Modeling and Simulation

Ray tracing software predicts light distribution enabling optimization before tooling commitment. Extraction pattern density calculations achieve target uniformity exceeding 85%. Coupling efficiency analysis maximizes light transfer from LEDs into guides. Color mixing simulations for RGB applications ensure uniform white point. Thermal modeling predicts temperature rise affecting LED performance and reliability. Tolerance analysis ensures robustness to manufacturing variations.

Electroluminescent Backlighting

Electroluminescent technology provides unique advantages for specific membrane switch applications despite limitations.

EL Lamp Construction

Phosphor layer between transparent and opaque electrodes emits light under AC excitation. Typical construction thickness of 0.2-0.4mm maintains switch assembly flexibility. Screen printing enables custom shapes matching specific graphic requirements. Segmented designs allow selective area illumination reducing power consumption. Encapsulation protects moisture-sensitive phosphors extending operational life. ITO-coated polyester provides transparent front electrode maintaining flexibility.

Driver Circuit Requirements

Inverters convert DC input to 100-200VAC at 400-1000Hz required for phosphor excitation. Output voltage determines brightness while frequency affects color and efficiency. Sine wave drivers reduce audible noise compared to square wave alternatives. EMI filtering prevents interference with sensitive electronic circuits. Dimming control through voltage or duty cycle adjustment enables brightness customization. Safety circuits limit output preventing shock hazards from exposed connections.

Performance Characteristics

Initial brightness of 30-150 cd/m² suitable for indoor and moderate outdoor visibility. Half-life of 3,000-10,000 hours requires replacement consideration in product design. Temperature affects brightness with 50% reduction at -40°C compared to room temperature. Humidity accelerates degradation requiring moisture barriers for extended life. Power consumption of 0.3-0.7mA/cm² at typical operating conditions. Color options limited to blue-green, white, and orange phosphor formulations.

Fiber Optic Illumination

Fiber optic systems provide unique solutions for challenging environments where electrical isolation is critical.

Fiber Optic System Design

Remote light source eliminates electrical components at switch location enhancing safety. LED or halogen sources couple into fiber bundles through focusing optics. Woven fiber panels distribute light uniformly across switch areas. Side-emitting fibers create linear lighting effects for borders or indicators. End-emitting fibers provide point illumination for discrete indicators. Flexible routing accommodates complex mechanical configurations.

Implementation Advantages

Intrinsically safe for explosive environments eliminating ignition sources at interface. EMI immunity prevents interference in sensitive electronic systems. No heat generation at switch surface maintaining comfortable touch temperature. Electrical isolation protects against high voltage and lightning strikes. Chemical resistance of glass fibers survives harsh industrial environments. Consistent color temperature maintained by single remote source.

Design Limitations

Higher initial cost compared to LED or EL backlighting systems. Light transmission losses of 3-5% per meter limiting practical distances. Mechanical protection required preventing fiber damage from crushing or sharp bends. Limited brightness compared to direct LED illumination methods. Complex assembly increases manufacturing time and costs. Replacement difficulty if fibers become damaged in service.

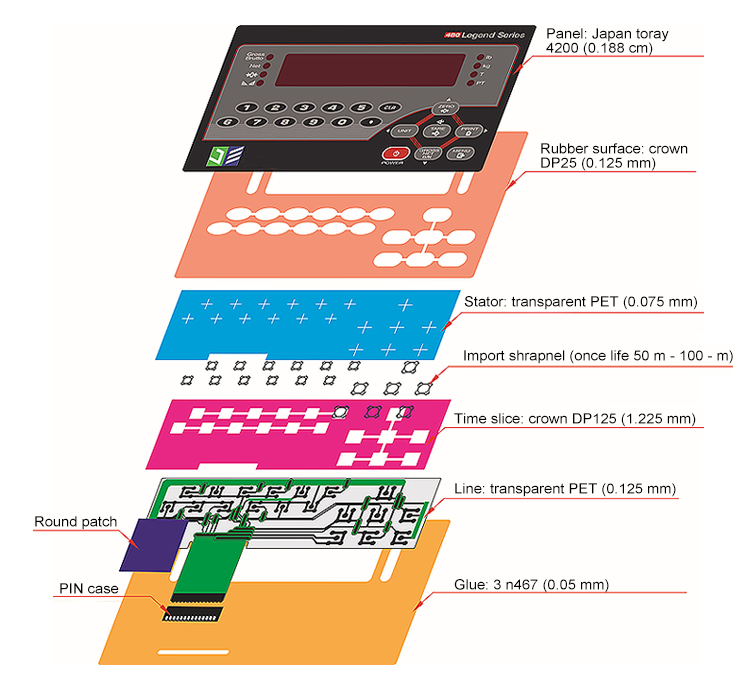

Design Considerations and Challenges

Successful backlit membrane switch design requires addressing multiple technical challenges simultaneously.

Optical Design Challenges

Hot spot elimination requires careful LED placement and diffusion techniques achieving <20% intensity variation. Color consistency across temperature maintains ΔE<3 preventing noticeable shifts. Viewing angle optimization ensures visibility from typical operator positions ±45°. Light leakage prevention through proper masking and sealing preserves graphic definition. Contrast ratio enhancement using selective opacity maintains readability in bright ambient conditions. Uniformity degradation over lifetime requires initial over-design compensating for LED aging.

Mechanical Integration

Tactile response preservation despite additional backlighting layers requires careful stackup design. Thickness minimization using thin light guides and flexible circuits maintains low profile. Flexibility retention accommodates installation on curved surfaces without damage. Adhesive compatibility prevents delamination from thermal cycling and aging. Stress relief features prevent damage at LED mounting locations during flexing. Environmental sealing integration maintains IP65+ rating despite additional components.

Thermal Management

LED junction temperature control maintains efficiency and extends operational life beyond 50,000 hours. Heat spreading using aluminum or copper substrates prevents localized hot spots. Thermal interface materials improve heat transfer from LEDs to heat sinks. Current derating at elevated temperatures prevents thermal runaway and premature failure. Ventilation considerations balance cooling requirements with environmental sealing. Thermal modeling validates designs before prototype fabrication.

Color and Brightness Management

Precise control of color and brightness ensures consistent appearance meeting design specifications.

Color Specification and Control

CIE chromaticity coordinates define precise color targets for backlit elements. White point specification typically targets 6500K (D65) for neutral appearance. Color temperature tolerance of ±500K maintains consistency across production. RGB mixing ratios achieve custom colors matching corporate branding requirements. Binning strategies group LEDs by color and brightness minimizing variation. Calibration procedures establish reference standards for production quality control.

Brightness Uniformity

Target uniformity exceeding 80% (min/max ratio) prevents visible brightness variations. Edge brightness compensation increases LED density near light guide perimeters. Diffusion films scatter light reducing visibility of individual LED sources. Multiple light zones enable selective dimming optimizing power consumption. Photometric measurement validates uniformity across entire illuminated area. Statistical process control maintains consistency throughout production runs.

Dimming and Control

Ambient light sensing automatically adjusts brightness optimizing visibility and power. PWM frequencies above 200Hz prevent visible flicker in peripheral vision. Logarithmic dimming curves match human perception for intuitive adjustment. Multi-zone control enables different brightness levels for various switch functions. Fade-in/fade-out effects provide sophisticated user experience feedback. Memory functions retain user preferences across power cycles.

Power Consumption and Efficiency

Optimizing power efficiency extends battery life and reduces heat generation in backlit membrane switches.

Power Budget Analysis

LED forward voltage and current determine individual device power consumption. Total system power includes LED, driver, and control circuit contributions. Duty cycle operation reduces average power for intermittent backlighting applications. Sleep modes disable backlighting during inactivity saving significant energy. Power distribution analysis identifies optimization opportunities reducing losses. Battery life calculations determine feasibility for portable applications.

Efficiency Optimization

High-efficiency LEDs exceeding 150 lumens/watt minimize power requirements. Switching regulators achieve 85-95% efficiency compared to 30-50% for linear regulators. Light recycling films reflect escaped light back into guides improving utilization. Selective illumination activates only required zones reducing total consumption. Adaptive brightness based on content reduces power while maintaining visibility. Component selection prioritizes efficiency within cost constraints.

Thermal Efficiency

Lower junction temperatures improve LED efficiency by 0.5% per degree Celsius reduction. Optimal drive current balances brightness against efficiency and heat generation. Pulse operation allows higher peak brightness while maintaining average temperature. Heat sink integration dissipates waste heat maintaining optimal operating conditions. Thermal feedback adjusts drive current preventing overheating in extreme conditions. Efficiency monitoring tracks degradation indicating maintenance requirements.

Environmental and Durability Factors

Backlit membrane switches must maintain performance across diverse environmental conditions throughout product lifetime.

Temperature Effects

LED output decreases 0.5-1% per degree Celsius requiring compensation in extreme temperatures. Cold temperatures increase LED forward voltage requiring driver headroom consideration. High temperatures accelerate phosphor degradation in both LEDs and EL lamps. Thermal cycling causes differential expansion potentially damaging solder joints and connections. Material selection ensures compatibility across -40°C to +85°C operating range. Conformal coating protects electronic components from thermal stress.

Moisture and Sealing

IP65 or higher sealing prevents moisture ingress damaging electronic components. Conformal coatings protect LED circuits from humidity and condensation. Breathable vents equalize pressure while maintaining moisture barriers. Gasket materials maintain compression and sealing throughout temperature range. Moisture-absorbing materials in sealed enclosures prevent condensation formation. Accelerated testing validates long-term performance in high-humidity environments.

Vibration and Shock

Secure LED mounting prevents fatigue failures from continuous vibration exposure. Flexible circuits accommodate movement without breaking solder connections. Strain relief features protect connections at rigid-to-flex transitions. Potting compounds stabilize components while maintaining thermal dissipation. Shock testing validates survival of drops and impacts during handling. Resonance analysis identifies problematic frequencies requiring damping.

Manufacturing and Assembly Integration

Efficient manufacturing processes ensure consistent quality and cost-effective production of backlit membrane switches.

Assembly Process Flow

LED placement using pick-and-place equipment ensures accurate positioning ±0.005". Reflow soldering profiles optimize joint reliability without damaging heat-sensitive components. Light guide insertion requires careful handling preventing scratches affecting optical performance. Layer lamination under controlled pressure and temperature ensures proper adhesion. Electrical testing validates all LED functions before final assembly. Optical inspection confirms uniform illumination meeting specifications.

Quality Control Methods

Incoming inspection verifies LED brightness and color within specified bins. In-process monitoring tracks assembly parameters ensuring consistency. Photometric testing measures brightness, uniformity, and color coordinates. Burn-in testing identifies early failures before product shipment. Environmental testing validates performance across specified conditions. Statistical sampling plans balance quality assurance with production efficiency.

Manufacturing Challenges

LED handling prevents ESD damage requiring proper grounding and procedures. Light guide cleanliness maintains optical performance requiring clean room environments. Registration between layers ensures proper alignment of optical and electrical elements. Adhesive selection balances optical clarity with mechanical reliability. Process validation demonstrates capability meeting quality requirements. Yield optimization reduces scrap through systematic improvement initiatives.

Frequently Asked Questions

What is the typical lifespan of LED backlighting in membrane switches?

How much power does membrane switch backlighting consume?

Can backlit membrane switches achieve uniform illumination?

What backlighting works best for outdoor applications?

How does temperature affect backlight performance?

What are the cost implications of adding backlighting?

Conclusion

Backlit membrane switches represent a critical enhancement transforming basic input devices into sophisticated user interfaces suitable for any lighting environment. Success requires careful integration of optical, electrical, and mechanical design elements while maintaining reliability and cost-effectiveness.

Design Best Practices

Begin with clear requirements defining brightness, uniformity, color, and environmental conditions. Select appropriate technology based on lifetime, power, and cost constraints rather than defaulting to familiar solutions. Implement thorough optical modeling before committing to tooling investments. Consider manufacturing capabilities early in design to ensure producibility. Validate designs through comprehensive testing including environmental and lifetime evaluation. Document design rules and lessons learned improving future developments.

Technology Evolution

Mini and micro-LED advances promise higher efficiency and improved local dimming capabilities. Quantum dot enhancement films expand color gamut for display applications. Flexible OLED integration enables new form factors and transparent displays. Smart lighting with sensors and adaptive control optimizes user experience. Sustainable materials and energy harvesting reduce environmental impact. Cost reductions through technology maturation expand application possibilities.

Implementation Strategy

Partner with experienced suppliers understanding both optical and membrane switch requirements. Invest in prototyping to validate concepts before production commitment. Plan for iterative refinement achieving optimal performance. Consider total system design including drivers, controls, and power management. Maintain flexibility for future upgrades as technology evolves. Focus on user experience ensuring backlighting enhances rather than distracts from primary function.

References

- Illumination Engineering Society - IES Lighting Handbook 10th Edition

- LED Professional Review - Advanced LED Driver Technologies (2024)

- Journal of Display Technology - Light Guide Plate Design Optimization

- SAE J2839 - LED Forward Lighting Performance Standards

- IPC-7351 - Generic Requirements for Surface Mount Design

- Optical Society of America - Handbook of Optics Volume II

- JASPER Backlighting Design Guidelines (2024)